Automatically backing weld method of pipeline MAG

A welding method and automatic welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems that the welding process cannot achieve automatic bottoming, the requirements of workers' operating skills are high, and the labor intensity is high, and the desalination operation can be achieved. Skills and labor intensity, the effect of solving high technical requirements and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

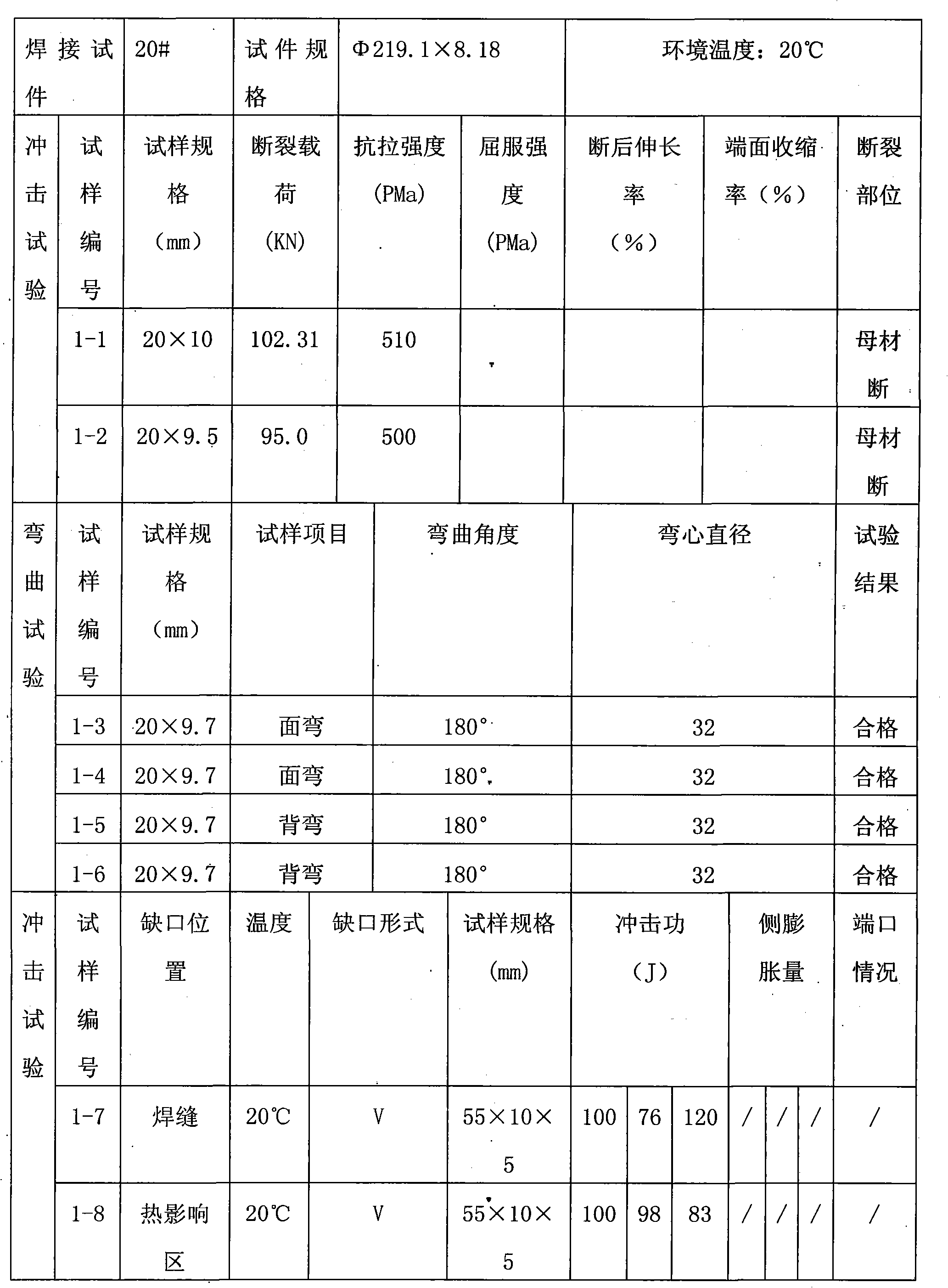

[0029] 20# steel Φ219.1×8.18 carbon steel pipe is used for automatic MAG bottom welding and filling cover welding with automatic welding equipment, and the operation is carried out according to the following steps: Working environment: 0℃~40℃

[0030] 1) Hardware preparation:

[0031] Adopt a set of automatic welding equipment that meets the following conditions:

[0032] 11) The high-performance requirements of the welding power supply, the input of the control line energy, and the high-performance digital pulse inverter power supply such as STT of Lincoln in the United States, ColdArc of EWM in Germany or CMT in Austria;

[0033] The arc control technology with low linear energy makes it possible for the automatic MAG bottoming welding process of the pipeline; precise control of the molten pool, less heat input, making the welding current smaller to about 50A, spatter-free welding, and continuous arc; and can achieve super power Arbitrary conversion of arc and pulse welding...

Embodiment 2

[0057] The carbon steel pipe of 20# steel Φ370×18 is used for automatic MAG bottom welding and filling cover welding with automatic welding equipment, and the welding process is the same as that of the first embodiment. Carry out X-ray flaw detection on the welded test piece: Level 1 is qualified.

Embodiment 3

[0059] The stainless steel 316LΦ119×16 pipeline is used for automatic MAG bottom welding and filling cover welding with automatic welding equipment, and the welding method and steps are the same as those in Example 1. The welding process parameters are as follows:

[0060] Groove form: V-shaped, 37.5° on one side, number of welding layers: 4 layers, one layer of bottom welding, three layers of filling welding, and one layer of cover.

[0061]Backing welding parameters:

[0062] Welding wire: Φ1.0, welding wire material: 316L; welding gas: Ar98%+CO22%; gas flow: 15-20L / min; welding speed: 100-200mm / min; welding current: 60A-150A; welding voltage: 18V- 23V; swing amplitude: 2~6mm; edge dwell time: 0.1~0.5s; torch angle: 30°~50°; gas flow at the back of the pipe: 20L / min. Welding degree: 365°.

[0063] Filling and covering parameters are (three layers):

[0064] Welding wire: Φ1.2, the wire material is selected according to the process requirements; welding gas: Ar98%+CO22%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com