Lead-free medium slurry and manufacturing method thereof

A lead-free medium and medium paste technology, applied in the field of lead-free medium paste and its manufacturing, can solve the problems of inability to use sealing, large thermal expansion coefficient of glass, deviation of bright colors, etc., to improve brightness and reduce energy consumption. , the effect of protecting the electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] 1. Preparation of lead-free glass powder

[0022] Put various inorganic materials into the mixing tank according to a certain proportion, mix evenly and pour into Al 2 o 3 The crucible is kept in a solid-phase sintering furnace at 1100°C-1300°C for 1 hour to obtain uniform glass liquid. The glass liquid passes through a glass flaker to obtain glass fragments. After these glass fragments are coarsely powdered, they are ball-milled with a ball mill to obtain ultra-fine particles. The glass powder has a particle size of 3-5 μm, so that the required lead-free glass powder is obtained.

[0023] 2. Preparation of backplane medium slurry

[0024] Mix the above-mentioned lead-free glass powder and coloring agent uniformly in a certain proportion, add an organic carrier, mix evenly, and then pass through a three-roll rolling mill to disperse the inorganic powder evenly in the organic carrier, thus obtaining the required covering electrode. Backplane media slurry.

[0025] 3....

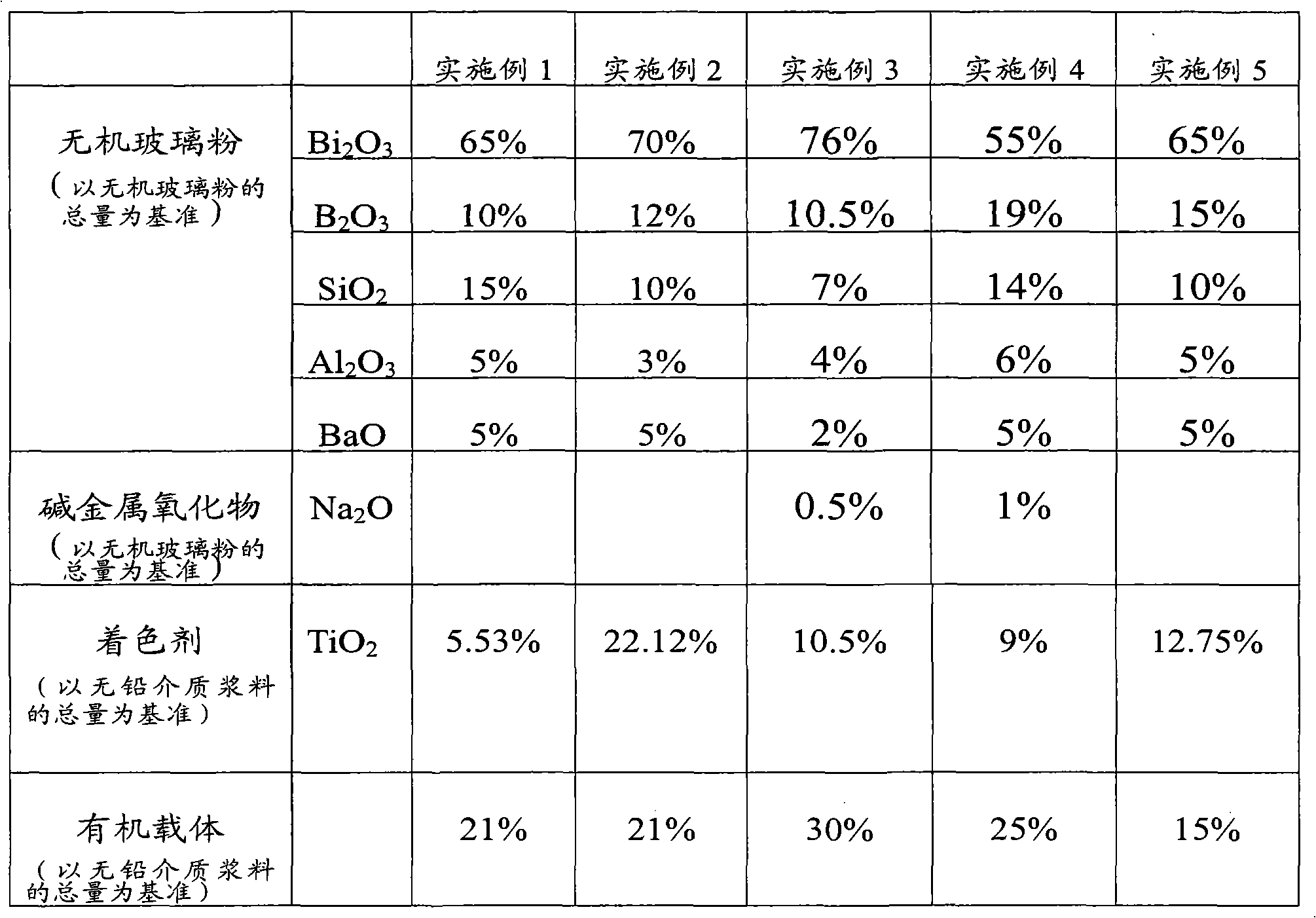

Embodiment 1

[0028] The composition ratio of lead-free glass powder is shown in Table 1. Prepare lead-free glass powder according to this formula, and then add TiO according to the weight ratio of lead-free glass powder and colorant 93:7 2 , mix evenly, add the organic vehicle prepared by EC 10wt%, BCA 20wt%, TE 40wt%, Texanol 30wt%, so that the solid content of the final lead-free medium slurry is 79%, after three-roll rolling mill Use a fineness meter to scrape the fineness below 5 μm, and the viscosity test is 18 Pa·s, so far the required backplane medium slurry is obtained.

[0029] Use a 325-mesh screen to print the above slurry on a 15cm×25cm glass, heat it at 150°C for 15 minutes, then keep it in a muffle furnace at 350°C for 20 minutes to completely remove the organic components in the paste, and finally heat it at 560°C Cool down after 20 minutes of sintering.

Embodiment 2

[0031] The composition ratio of the lead-free glass powder is shown in Table 1 below. Prepare lead-free glass powder according to this formula, and then add TiO according to the weight ratio of lead-free glass powder and colorant 72:28 2 , mix evenly, add the organic vehicle prepared by EC 10wt%, BCA 20wt%, TE 40wt%, Texanol 30wt%, the solid content of the final lead-free medium slurry is 79%, finely The scraping fineness of the meter is below 5 μm, and the viscosity test is 21 Pa·s. So far, the required backplane medium slurry has been obtained.

[0032] Use a 325-mesh screen to print the above slurry on a 15cm×25cm glass, heat it at 150°C for 15 minutes, then keep it in a muffle furnace at 350°C for 20 minutes to completely remove the organic components in the paste, and finally heat it at 560°C Cool down after 20 minutes of sintering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com