New method for producing dihydromyrcene

A technology of dihydromyrcene and pyrolysis products, which is applied in the field of chemical technology, can solve the problems of increased system operating costs, waste of energy, and the need for cooling media, and achieve low production energy consumption and cost, reduced production costs, and full utilization of heat energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

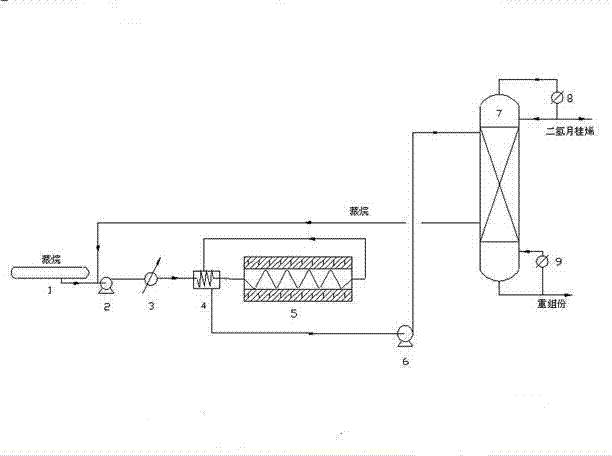

Image

Examples

Embodiment 1

[0016] The cracking furnace temperature is controlled at 500°C, the raw material pinane is mixed with the pinane recycled from the refining tower, and then it is preheated to 450°C and then enters the cracking furnace with a space velocity of 0.1 mol·ml-1·h-1, the single-pass conversion of pinane cracking The rate is 35%, the total conversion rate is 100%, and the selectivity of generating diclear myrcene is 83%. The pressure of the two-purity myrcene refining tower is controlled at 2-10kPa, and the concentration of dihydromyrcene obtained at the top of the tower can reach more than 85%. Using pyrolysis products to exchange heat with raw materials can save heat. The remaining steps are as described in the detailed description.

Embodiment 2

[0018] The cracking furnace temperature is controlled at 500°C, the raw material pinane is mixed with the pinane recycled from the refining tower, and then it is preheated to 450°C and then enters the cracking furnace with a space velocity of 0.128mol·ml-1·h-1, the single-pass conversion of pinane cracking The rate is 55%, the total conversion rate is 100%, and the selectivity of generating diclear myrcene is 83%. The pressure of the two-purity myrcene refining tower is controlled at 2-10kPa, and the concentration of dihydromyrcene obtained at the top of the tower can reach more than 85%. The remaining steps are as described in the detailed description.

Embodiment 3

[0020] The cracking furnace temperature is controlled at 520°C, the raw material pinane is mixed with the pinane recycled from the refining tower, and then it is preheated to 450°C and then enters the cracking furnace with a space velocity of 0.1mol·ml-1·h-1, the single-pass conversion of pinane cracking The rate is 65%, the total conversion rate is 100%, and the selectivity of generating diclear myrcene is 80%. The pressure of the two-purity myrcene refining tower is controlled at 2-10kPa, and the concentration of dihydromyrcene obtained at the top of the tower can reach more than 85%. The remaining steps are as described in the detailed description.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com