Method of producing nitrided li-ti compound oxide, nitrided li-ti compound oxide, and lithium-ion battery

A composite oxide, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as battery voltage reduction and potential difference reduction, and achieve the effect of low reduction potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

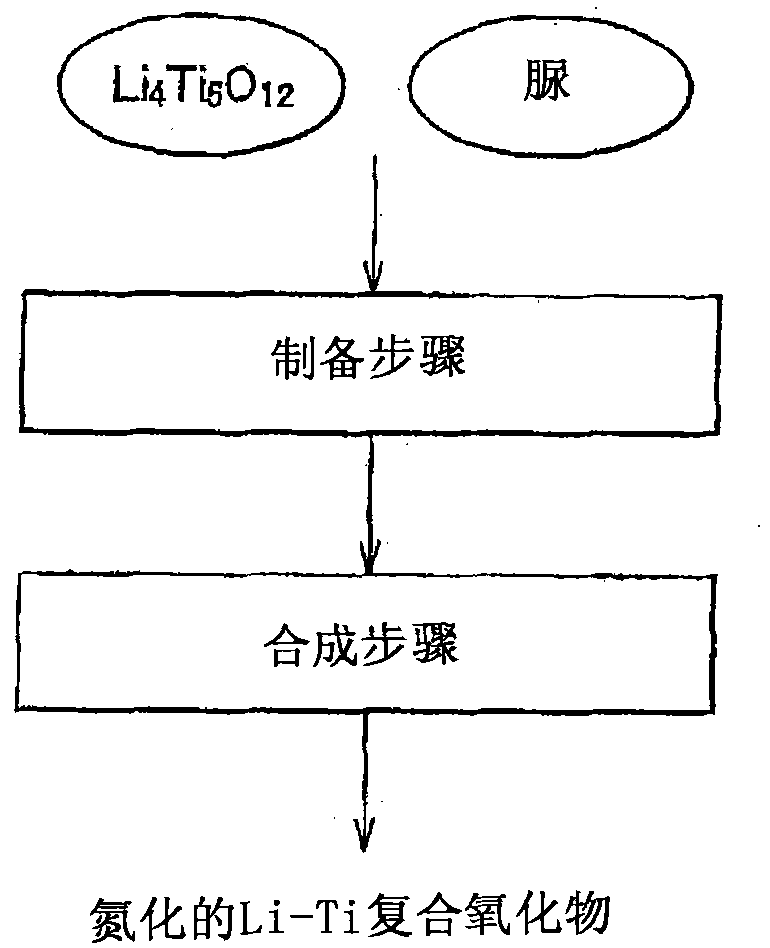

[0047] The preparation step of the present invention is a step of preparing a raw material composition comprising a raw material containing Li, Ti, and O and nitrogen represented by the above general formula (1) and which is solid or liquid at room temperature (25° C.) agent.

[0048] (1) Raw material

[0049] In the present invention, the raw material contains Li, Ti and O. The raw material may be a Li—Ti composite oxide (raw material compound), or may be a mixture of various compounds (raw material mixture) from which a Li—Ti composite oxide can be synthesized. Each of these cases will be described below.

[0050] (i) When the raw material is Li-Ti composite oxide

[0051] In this case, the raw material is not particularly limited as long as the raw material is a compound (Li—Ti composite oxide) containing all of Li, Ti, and O. Examples of such Li-Ti composite oxides include composite oxides having a spinel structure and composite oxides having a ramsdellite structure. ...

no. 1 approach

[0082] The first embodiment of the nitrided Li-Ti composite oxide of the present invention is a nitrided Li-Ti composite oxide having Li, Ti, O, and N and characterized by being in a crystalline state. The fact that the nitrided Li-Ti composite oxide is crystalline can be confirmed by X-ray diffraction (XRD).

[0083] The first embodiment provides a nitrided Li-Ti composite oxide having a low reduction potential. In addition, since this nitrided Li-Ti composite oxide is in a crystalline state, it has the advantage that the reversibility of Li ion insertion and extraction is higher compared to the case where the nitrided Li-Ti composite oxide is in an amorphous state. And the battery voltage is more highly stable. Above JP-A-2006-32321 No. description, active material is amorphous (for example its claim 2 and image 3 ). However, it is not stated therein that the active material is in a crystalline state. Even when Li-Ti composite oxides (such as Li 4 Ti 5 o 12 ) during ...

no. 2 approach

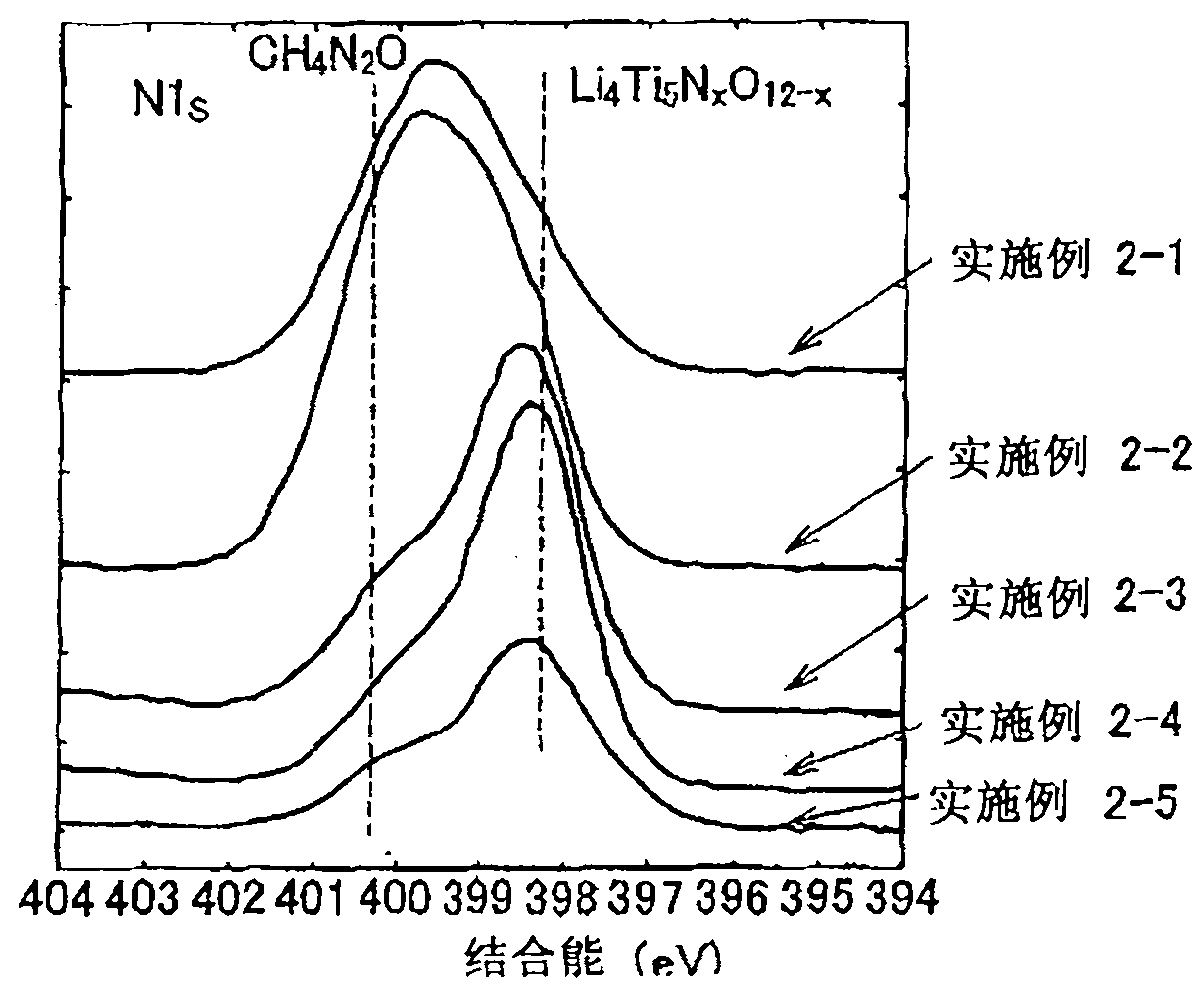

[0091] Next, a second embodiment of the nitrided Li-Ti composite oxide of the present invention will be described. Nitrided Li-Ti composite oxide of the second embodiment is a nitrided Li-Ti composite oxide having Li, Ti, O, and N and characterized by being composed of Li a Ti b o c N d Compounds represented by (0

[0092]According to the second embodiment, since the nitrided Li—Ti composite oxide has the above composition, a nitrided Li—Ti composite oxide having a low reduction potential is obtained. In No. JP-A-2006-32321 cited above, a general formula: Li x TiO y N z (wherein 0≤x≤2, 0.1x Ti 5 o Y N Z (Where 0≤X≤10, 0.5a Ti b o c (e.g. Li 4 Ti 5 o 12 ) in the case of nitriding, the nitrided Li-Ti composite oxide represented by the above general formula (B-1) cannot be obtained either. When ammonia is used, sufficient nitriding cannot be performed, so i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com