Method for preparing molybdenum disulfide from molybdenite

A technology of molybdenum disulfide and molybdenite, applied in the direction of molybdenum sulfide, etc., can solve the problems of instability and poor quality of molybdenum disulfide, achieve the effects of shortening leaching time, convenient operation, and improving leaching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

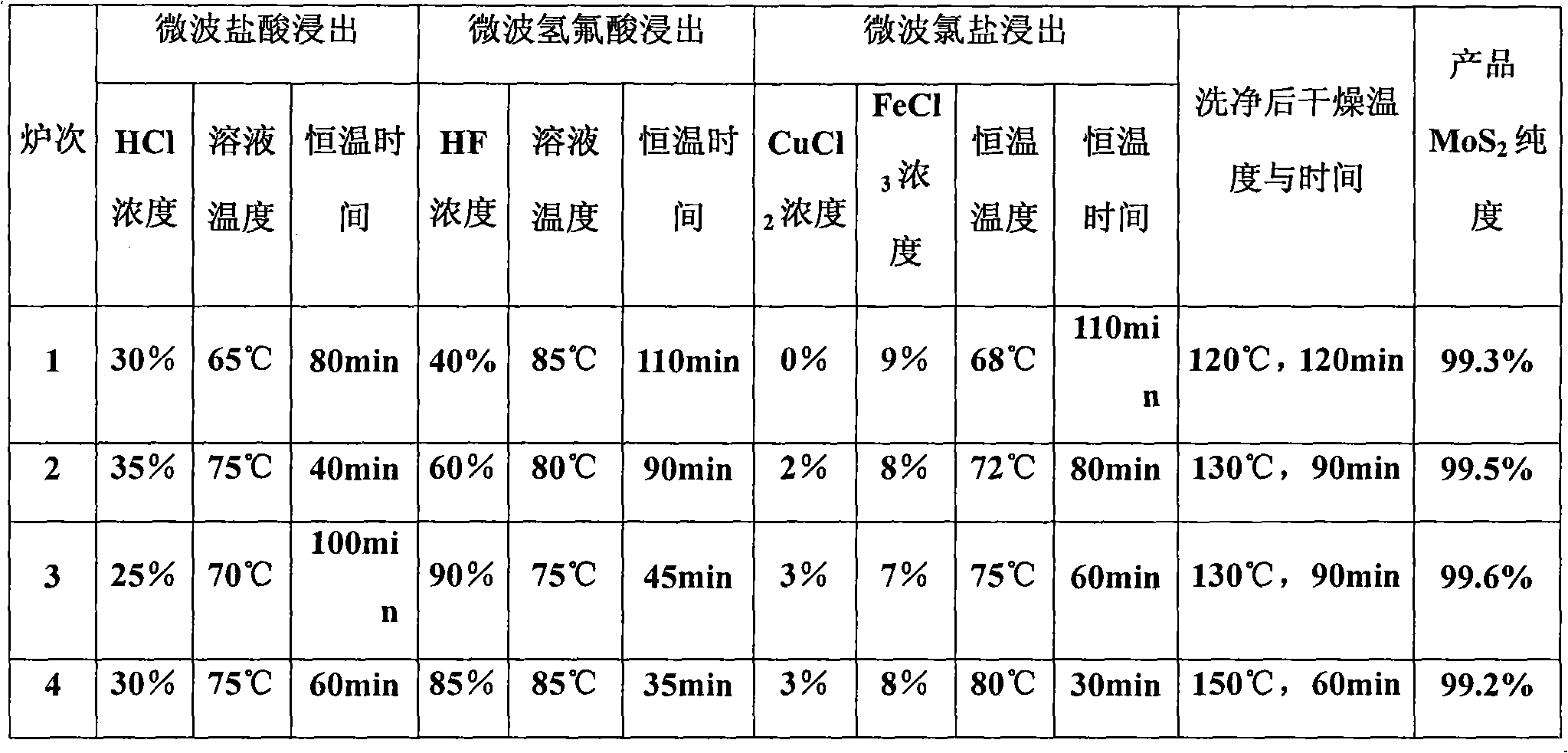

Examples

Embodiment 1

[0031] The first step microwave assisted hydrochloric acid leaching:

[0032] 1) First put 100kg of molybdenite powder into a hydrochloric acid leaching kettle with microwave-assisted heating, the concentration of hydrochloric acid is 30%, and the dosage is 100kg;

[0033] 2) Heating with microwaves, controlling the temperature of the liquid in the leaching kettle at 65°C, and the constant temperature time is 80min;

[0034] 3) Turn off the microwave, and separate the acid liquid from the powder.

[0035] The second step microwave assisted hydrofluoric acid leaching:

[0036] 1) Put the powder leached by microwave hydrochloric acid into a hydrofluoric acid leaching kettle with microwave-assisted heating, the concentration of hydrofluoric acid is 40%, and the dosage is 100kg;

[0037] 2) Heating by microwave, controlling the temperature of the liquid in the leaching tank at 85°C, and the constant temperature time is 110min;

[0038] 3) Turn off the microwave, and separate th...

Embodiment 2

[0045] The first step microwave assisted hydrochloric acid leaching:

[0046] 1) First put 100kg of molybdenite powder into a hydrochloric acid leaching kettle with microwave-assisted heating, the concentration of hydrochloric acid is 35%, and the consumption is 95kg;

[0047] 2) Heating by microwave, controlling the temperature of the liquid in the leaching tank at 75°C, and the constant temperature time is 40min;

[0048] 3) Turn off the microwave, and separate the acid liquid from the powder.

[0049] The second step microwave assisted hydrofluoric acid leaching:

[0050] 1) Put the powder leached by microwave hydrochloric acid into a hydrofluoric acid leaching kettle with microwave-assisted heating, the concentration of hydrofluoric acid is 60%, and the dosage is 95kg;

[0051] 2) Heating by microwave, the temperature of the liquid in the leaching tank is controlled at 80°C, and the constant temperature time is 90min;

[0052] 3) Turn off the microwave, and separate the...

Embodiment 3

[0059] The first step microwave assisted hydrochloric acid leaching:

[0060] 1) First put 100kg of molybdenite powder into a hydrochloric acid leaching kettle with microwave-assisted heating, the concentration of hydrochloric acid is 25%, and the dosage is 60kg;

[0061] 2) Heating by microwave, controlling the temperature of the liquid in the leaching tank at 70°C, and the constant temperature time is 100min;

[0062] 3) Turn off the microwave, and separate the acid liquid from the powder.

[0063] The second step microwave assisted hydrofluoric acid leaching:

[0064] 1) Put the powder leached by microwave hydrochloric acid into a hydrofluoric acid leaching kettle with microwave-assisted heating, the concentration of hydrofluoric acid is 90%, and the dosage is 60 kg;

[0065] 2) Heating with microwaves, controlling the temperature of the liquid in the leaching kettle at 75°C, and the constant temperature time is 45min;

[0066] 3) Turn off the microwave, and separate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com