Subsurface flow constructed wetland system of secondary effluent from sewage treatment plant and application thereof

A technology for a constructed wetland system and a sewage treatment plant, applied in the field of water treatment, can solve the problems of backward technology, expensive membrane modules, complicated operation management, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

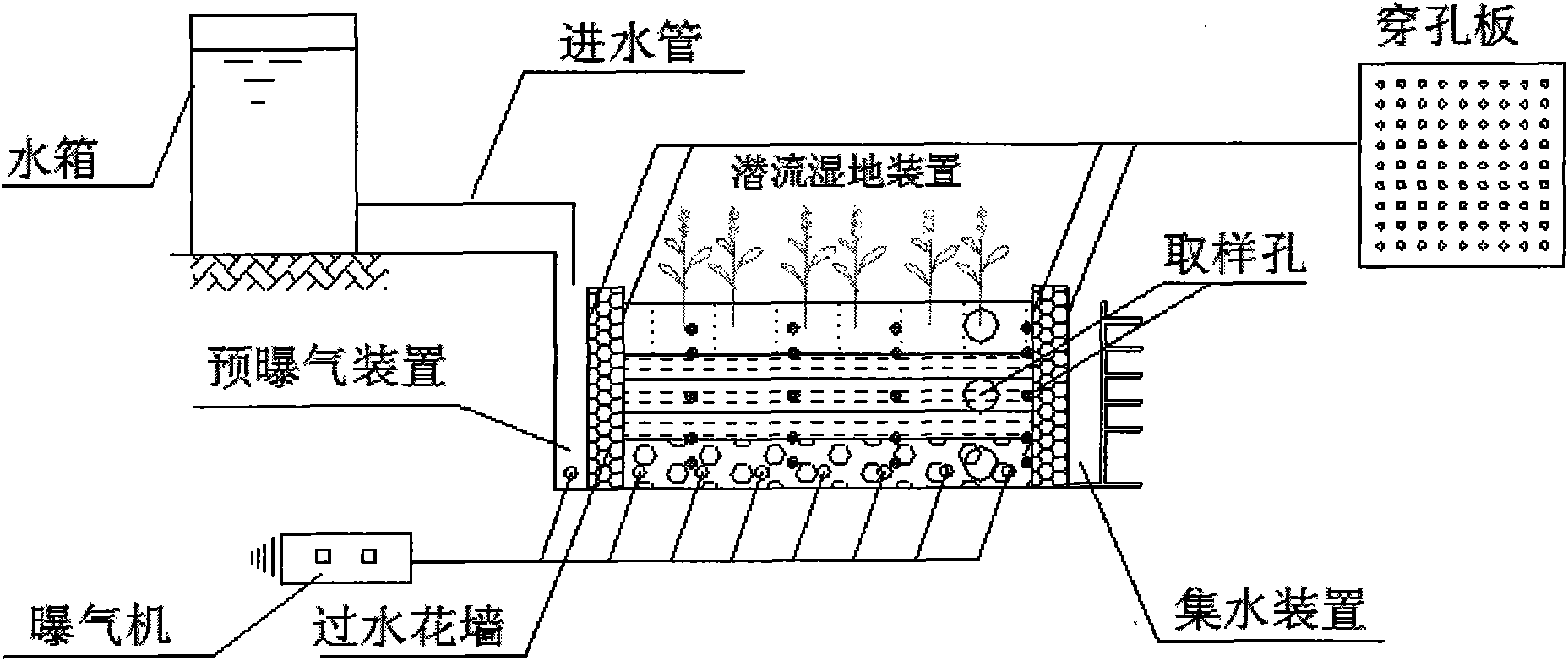

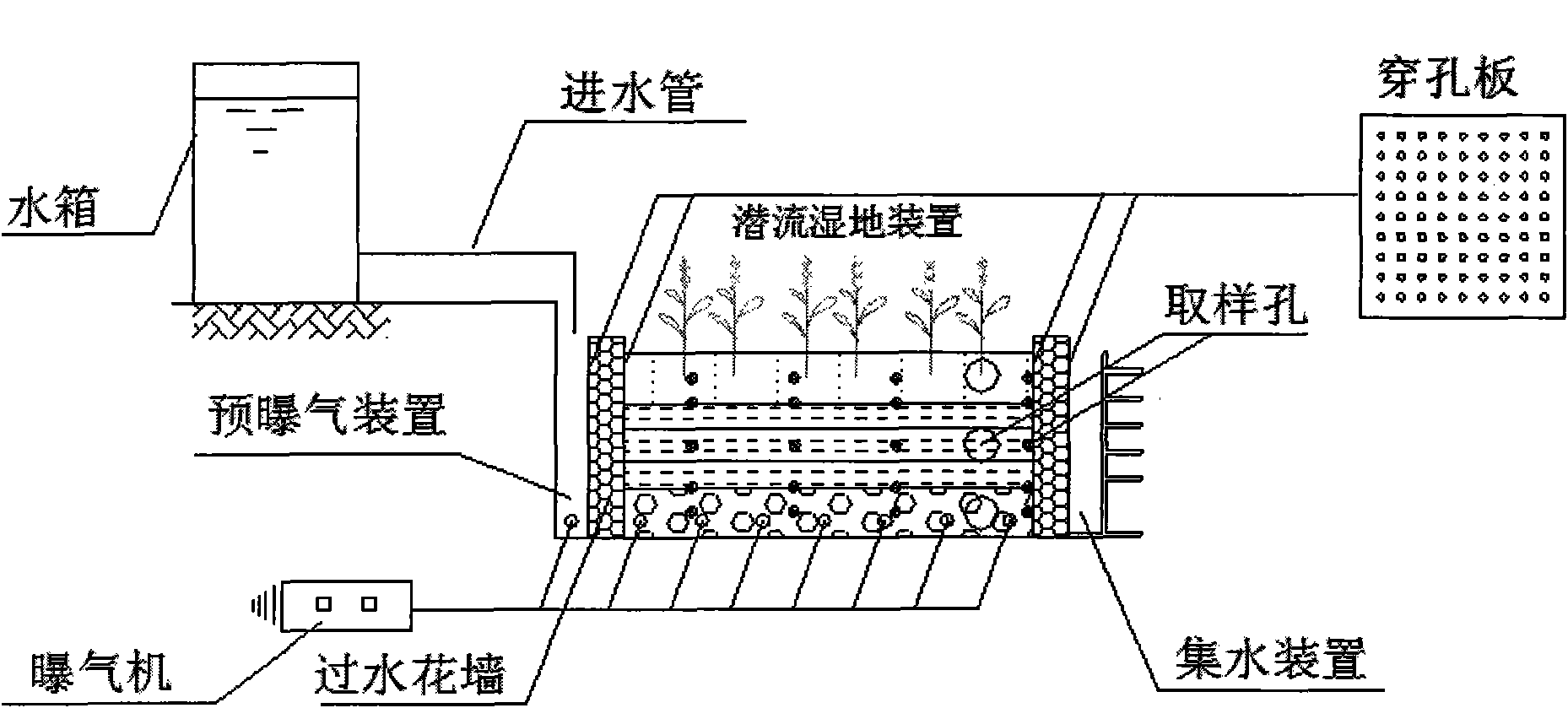

[0028] Such as figure 1 , figure 2 As shown, the subsurface flow constructed wetland system of the present invention is to allow the sewage to pass through the subsurface flow constructed wetland after pre-aeration, and the influent load is 0.6-1.2m 3 / (m 2 · Within the scope of d), obtain clear water that meets the Class III standard of "Surface Water Environmental Quality Standard (GB3838-2002)".

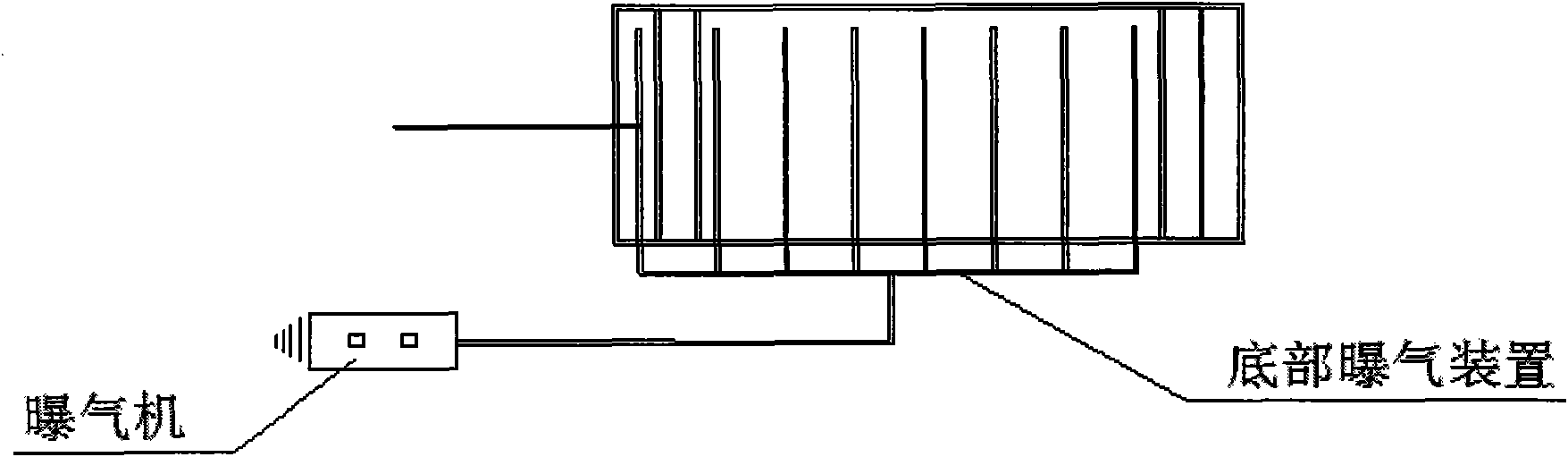

[0029] The pre-aeration device of the present invention is a box structure, an aeration pipe connected to an aerator is arranged at the bottom of the box, and small holes with the same diameter are evenly punched on the aeration pipe. The volume ratio of the pre-aeration device and the subsurface constructed wetland device is 1 / 12-1 / 8, the inner diameter of the circular tube is 8-12mm, and the diameter of the small holes on the circular tube is 2-4mm. According to the needs, the aerator can choose the appropriate model.

[0030] The subsurface flow wetland device and the pre-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com