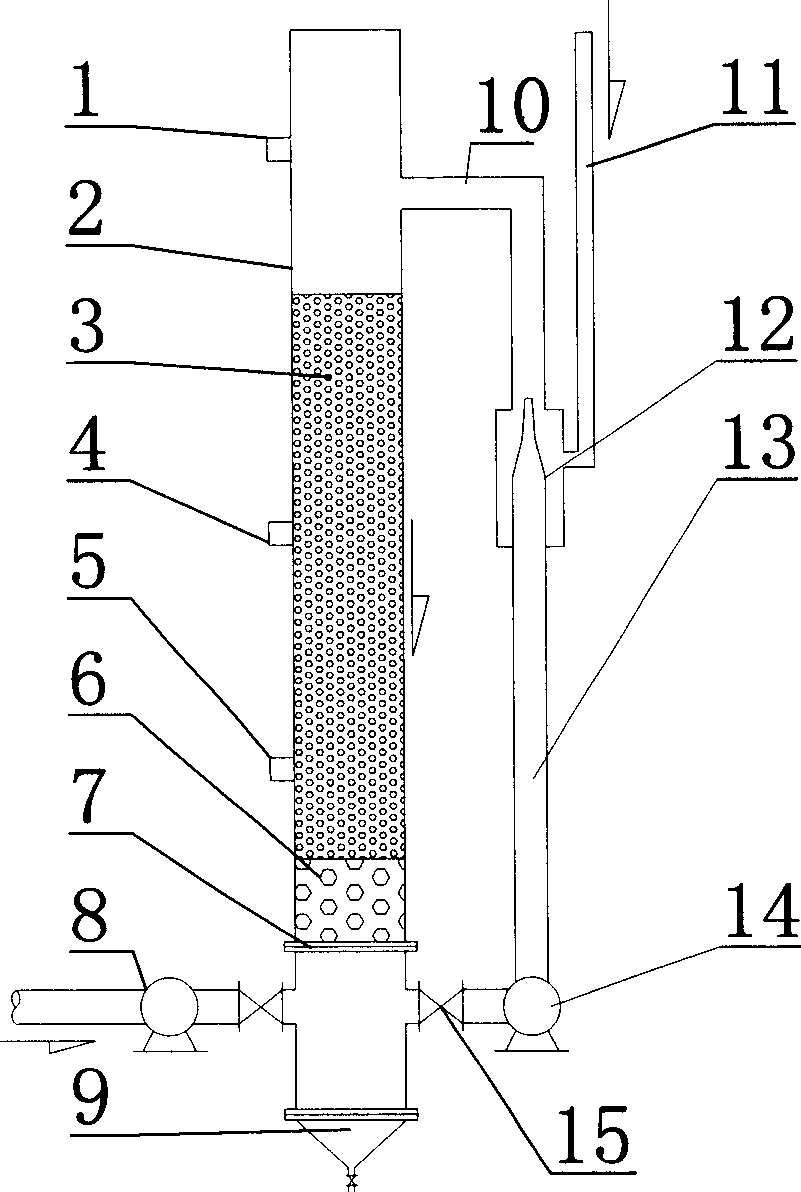

Jet-flow aeration biological filtering tank

A technology of jet aeration and biological filter, which is applied in the field of jet aeration biological filter and sewage treatment device, can solve the problems of small sewage treatment plants with many structures and complicated maintenance and management, and achieves a wide range of water quality adaptation and suspended solids concentration. The effect of low and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023]To treat domestic sewage in Minhang District, Shanghai, the biological oxidation filter tank 2 has an effective volume of 40L, a hydraulic retention time of 4 hours, a sewage treatment capacity of 10L / hr, a flow rate of the circulating water pump 14 of 45L / h, and a jet aerator 12 A small experimental device is used, the aperture ratio is 1:5, and the raw water quality is as follows: COD (chemical oxygen demand) 350mg / L, BOD 5 It is 159mg / L, ammonia nitrogen is 10mg / L, total nitrogen is 30mg / L, total phosphorus is 3mg / L, and suspended matter is 25mg / L. After being treated by jet aerated biological filter, the effluent COD30mg / L, BOD 5 The ammonia nitrogen is 5mg / L, the ammonia nitrogen is 3.5mg / L, the total phosphorus is 1mg / L, and the total nitrogen is 10mg / L. The effluent meets the first-class A standard of "Pollutant Discharge Standards for Urban Sewage Treatment Plants" (GB18918-2002), and has been disinfected Afterwards, it can be used as municipal reuse water or it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com