Method for reduction, evaporation and concentration treatment of wastewater produced by acidic precipitation of vanadate-leaching solution

A technology of vanadium precipitation and evaporative concentration of acid ammonium salts, which is applied in the fields of reduced water/sewage treatment, flocculation/sedimentation water/sewage treatment, water/sewage treatment, etc. efficiency, affecting the stable operation of production, etc., to achieve the effect of high separation efficiency, low cost and high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

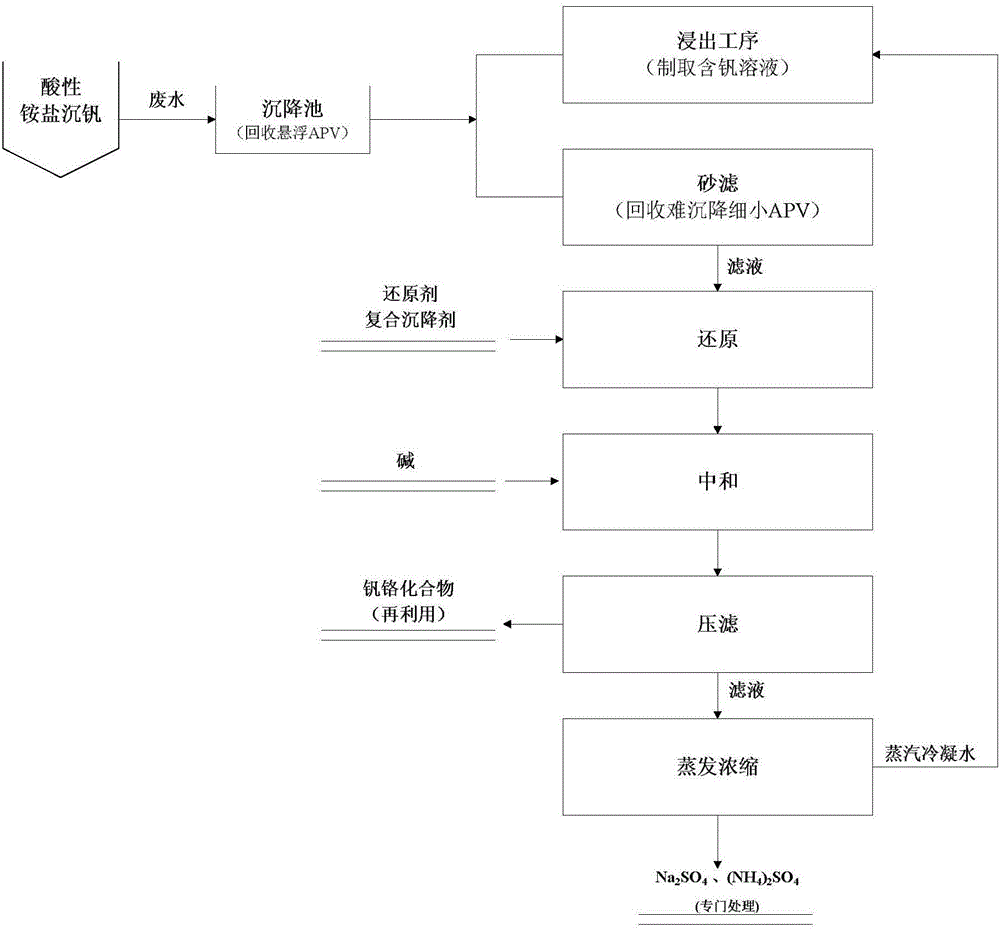

Method used

Image

Examples

Embodiment 1

[0039] Load 20 tons of vanadium extraction residue into 10 suction filtration tanks, the thickness of the residue layer is 500mm-800mm, and the continuous suction filtration is 100m 3 Acidic ammonium salt precipitation vanadium wastewater, in the obtained filtrate [Cr 6+ ]=2.0g / L~2.5g / L, [V 5+]=0.29g / L~0.40g / L, according to 6~7kg sodium metabisulfite / m 3 Add sodium metabisulfite to the proportion of waste water to carry out reduction reaction under stirring conditions, add 0.8‰~1‰ of activated carbon and cellulose (the mass ratio of activated carbon and cellulose is 1~5:1) composite sedimentation agent, add 30% of Liquid caustic soda adjusts the pH value of the solution to 7-8, and the vanadium-chromium compound is precipitated. The vanadium-chromium compound slurry is filtered through a plate and frame filter press to achieve solid-liquid separation, and the filtrate enters the four-effect evaporation concentration system for heating and concentration. When it reaches 35% t...

Embodiment 2

[0041] Load 24 tons of vanadium extraction residue into 12 suction filtration tanks, the thickness of the residue layer is 500mm-800mm, and the continuous suction filtration is 100m 3 Acidic ammonium salt precipitation vanadium wastewater, in the obtained filtrate [Cr 6+ ]=1.8g / L~2.7g / L, [V 5+ ]=0.25g / L~0.45g / L, according to 5~8kg sodium metabisulfite / m 3 Add sodium sulfite to the proportion of waste water to carry out the reduction reaction under stirring conditions, add 1.0‰~1.5‰ of activated carbon and cellulose composite sedimentation agent (mass ratio of activated carbon and cellulose is 1~5:1), add 30% liquid Alkali adjusts the pH value of the solution to 7-8, and the vanadium-chromium compound is precipitated. The vanadium-chromium compound slurry is filtered through a plate and frame filter press to achieve solid-liquid separation, and the filtrate enters the four-effect evaporation concentration system for heating and concentration. At 35% to 40%, the discharge syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com