White spirit prepared by fermenting and distilling pseudo-ginseng root dregs and method

A technology of notoginseng slag and liquor, applied in the field of liquor prepared by brewing, fermentation and distillation, to achieve high yield, improve resource utilization, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

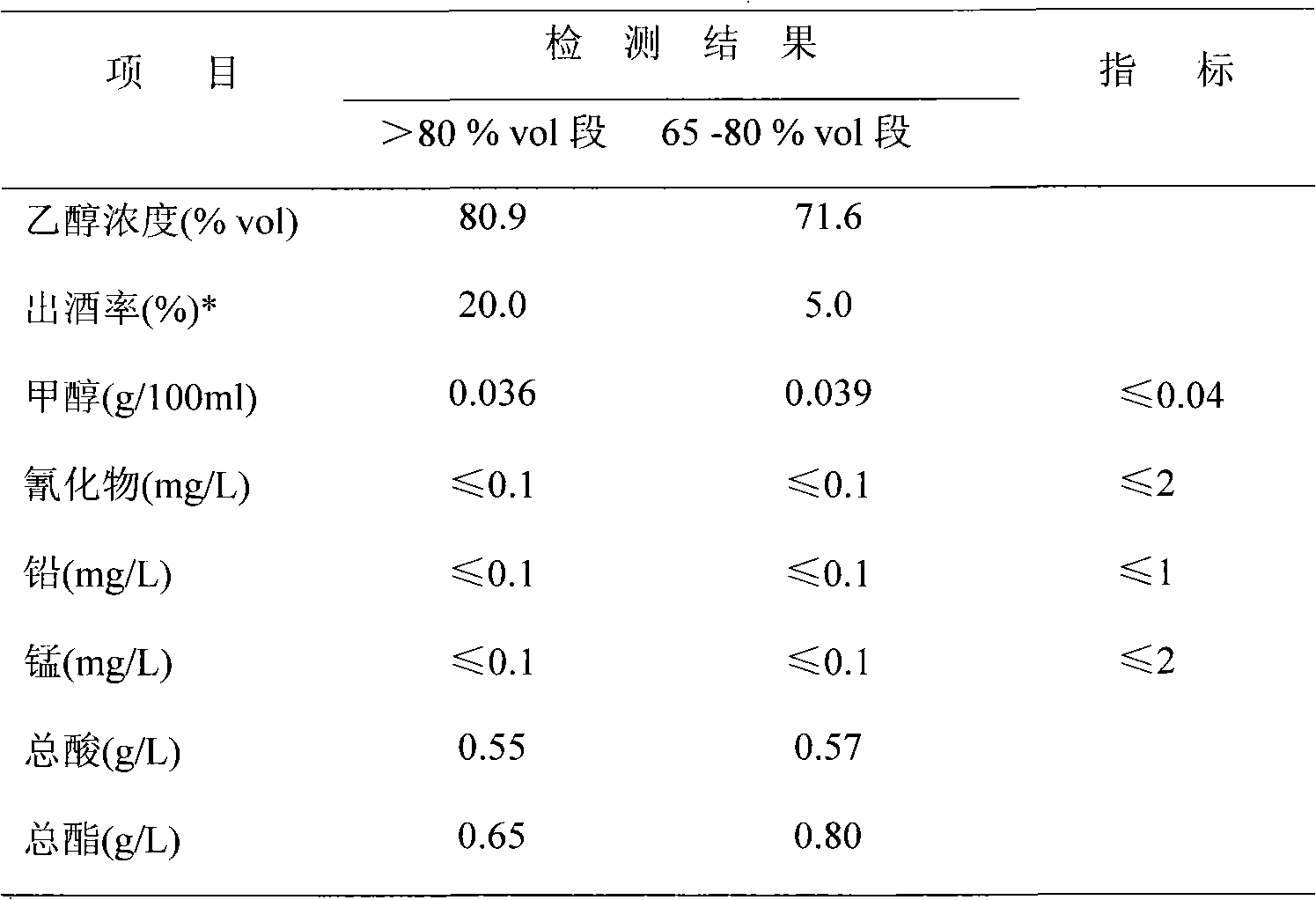

Embodiment 1

[0032] (1) Raw materials: take 8kg of notoginseng slag, sprinkle 4kg of hot water at 95°C on the surface of the notoginseng slag twice, mix evenly for several times, accumulate and moisten for 18 hours.

[0033] (2) Steaming material: Steam the moistened notoginseng slag for 3 hours in a retort, and sprinkle the material evenly by steaming when putting on the retort.

[0034] (3) Measure the water: take the steamed notoginseng slag out of the steamer, and immediately sprinkle 1kg of hot water at 85°C to replenish the moisture lost during steaming.

[0035] (4) Mixing koji: the material after splashing water is spread out to cool, and when the temperature drops to 34°C, add 0.2kg of medium-temperature Daqu powder, and mix it evenly several times.

[0036] (5) Saccharification: After the distiller's yeast powder is stirred, it is piled up, and the saccharification is started, and the saccharification time is 50 hours.

[0037] (6) Fermentation: Mix the saccharified fermented gr...

Embodiment 2

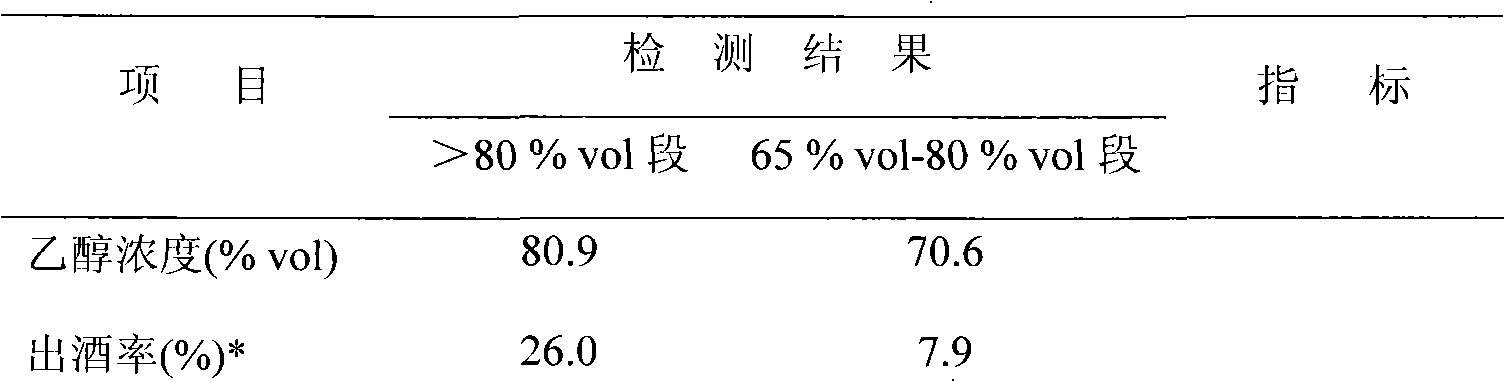

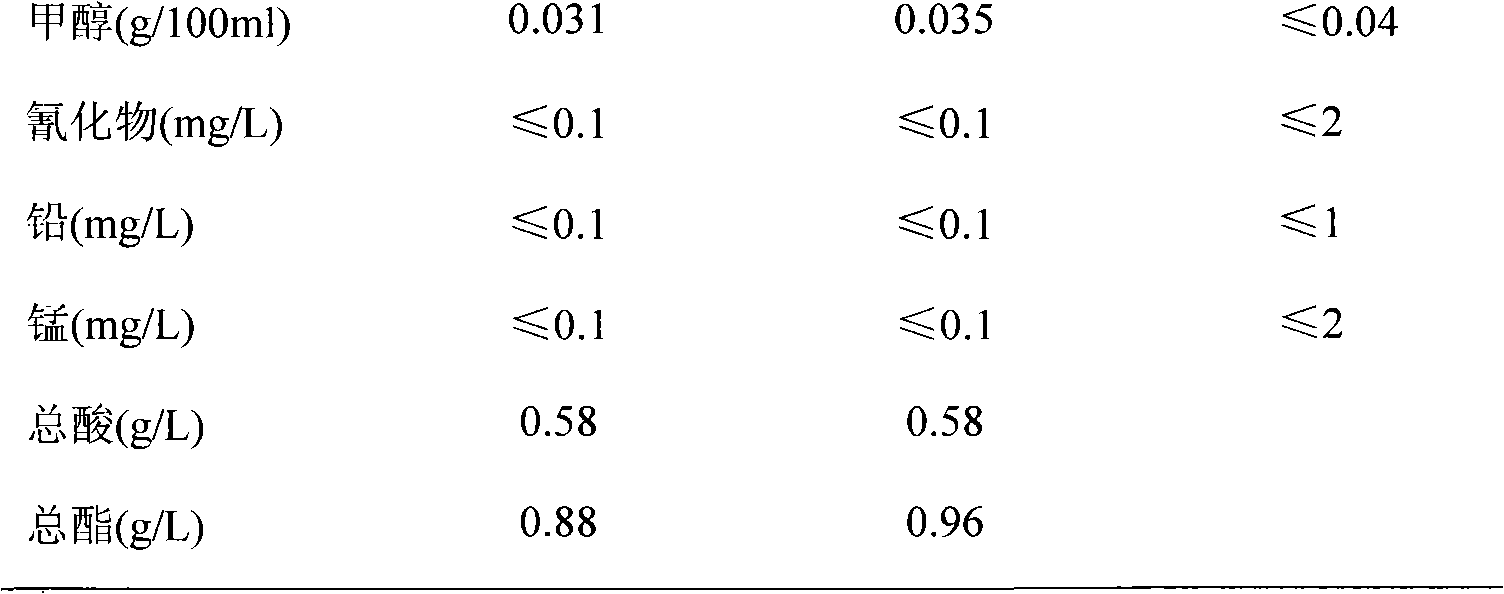

[0044] (1) Raw materials: After mixing 4 kg of notoginseng slag with 4 kg of sorghum (crushed), sprinkle 6 kg of hot water at 93°C on the surface of notoginseng slag three times, mix evenly for several times, accumulate and moisten for 15 hours.

[0045] (2) Steaming material: Steam the moistened notoginseng slag in a retort for 3.5 hours. When putting on the retort, sprinkle the material evenly by steaming.

[0046] (3) Measure the water: take the steamed notoginseng slag out of the steamer, and immediately sprinkle 0.95 kg of hot water at 87°C to replenish the moisture lost during steaming.

[0047] (4) Mixing koji: the material after splashing water is spread out to cool, and when the temperature drops to 32°C, add 0.5kg of high-temperature Daqu powder, and mix it evenly several times.

[0048] (5) Saccharification: the distiller's koji powder is stirred and piled up. The saccharification time is 48 hours.

[0049] (6) Fermentation: Mix the saccharified fermented grains e...

Embodiment 3

[0057] (1) Raw materials: take 200kg of notoginseng slag, sprinkle 100kg of hot water at 93°C on the surface of notoginseng slag three times, mix it evenly for several times, accumulate and moisten it for 15 hours.

[0058] (2) Steaming material: Steam the moistened notoginseng slag in a retort for 3.0 hours. When putting on the retort, sprinkle the material evenly by steaming.

[0059] (3) Look at the water: take the steamed notoginseng residue out of the steamer, and immediately sprinkle 25kg of hot water at 85°C to supplement the moisture lost during steaming.

[0060] (4) Mixing koji: the material after splashing water is spread out to cool, and when the temperature drops to 25°C, add 20kg of koji powder, and mix evenly several times.

[0061] (5) Saccharification: koji powder is stirred and piled up for saccharification. The saccharification time was 120 hours.

[0062] (6) Fermentation: the saccharified fermented grains are mixed well, after mixing well, the fermented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com