Engineering colon bacillus for preparing biological gasoline

A technology of Escherichia coli and biogasoline, applied in the direction of microorganism-based methods, microorganisms, petroleum industry, etc., can solve the problems of poor quality, easy solidification, and high viscosity of biodiesel, and achieve the effect of easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]By co-overexpressing the acetyl-CoA carboxylase gene (accABCD) of A. calcoaceticus, the BTE gene of U. californica, the acr1 gene of A. calcoaceticus and the CER1 gene of A. thaliana in E. coli, and knocking out the E. coli The fadE gene is used in the biosynthesis of short- and medium-chain alkanes.

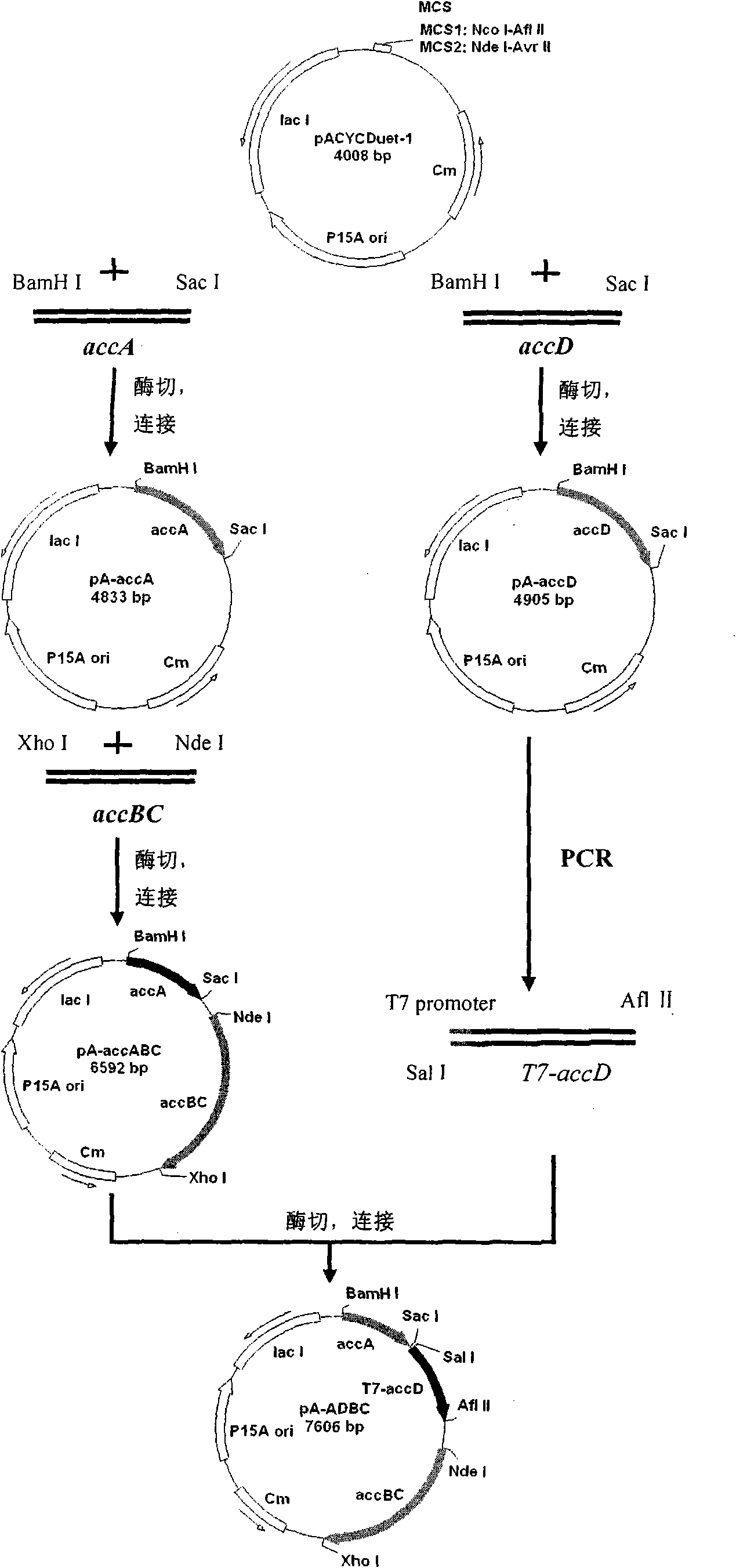

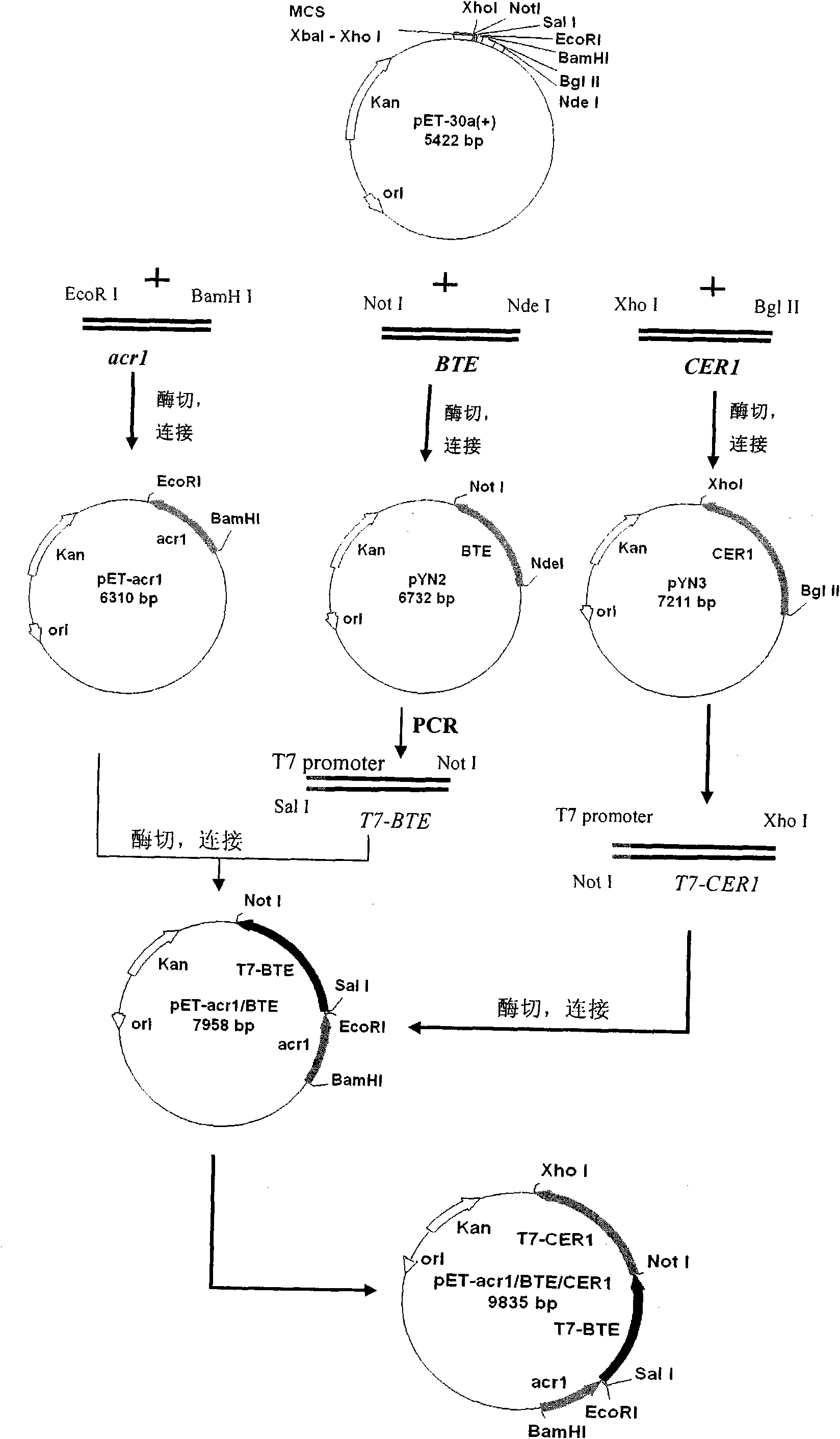

[0031] 1.1) Cloning of foreign genes and construction of expression vectors

[0032] 1.1.1) Cloning of foreign genes

[0033] 1.1.1.1) Cloning of A. calcoaceticus acetyl-CoA carboxylase gene

[0034] A. calcoaceticus genomic DNA was extracted, primers were designed according to the GenBank sequence, and the following genes were amplified by PCR:

[0035] accA: acetyl-coenzyme A carboxylase carboxyltransferase (alpha subunit) GeneID (NCBI): 2878570;

[0036] accBC (including accB and accC genes): accB: biotin carboxyl carrier protein of acetyl-CoA, GeneID (NCBI): 2878571; accC: acetyl-CoA carboxylase, GeneID (NCBI): 2878572;

[0037] accD: acetyl-CoA carboxylase, beta s...

Embodiment 2

[0079] Cc FatB of C. calophylla by co-overexpressing the acetyl-CoA carboxylase gene (accABCD) of A. calcoaceticus in E. coli 2 genes, the acr1 gene of A. calcoaceticus and the CER1 gene of A. thaliana, and the fadE gene of E. coli was knocked out for the biosynthesis of short and medium chain alkanes. Method process is the same as embodiment 1.

Embodiment 3

[0081] Ch FatB of C. hookeriana by co-overexpressing the acetyl-CoA carboxylase gene (accABCD) of A. calcoaceticus in E. coli 2 genes, the acr1 gene of A. calcoaceticus and the CER1 gene of A. thaliana, and the fadE gene of E. coli was knocked out for the biosynthesis of short and medium chain alkanes. Method process is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com