Thin-film solar cell

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unreasonable design of solar cell modules, and achieve the effects of reasonable thickness, increased power, and increased power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

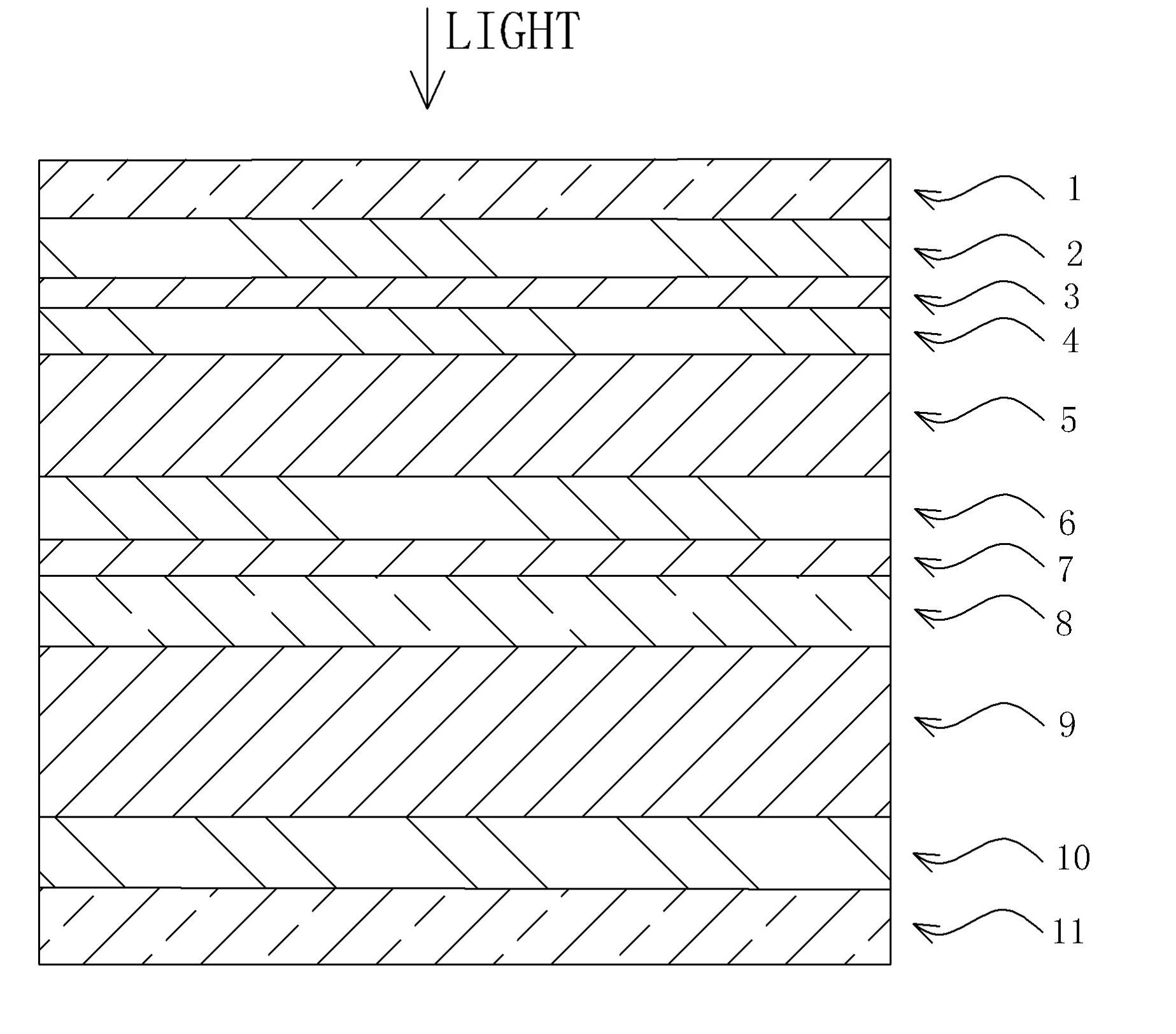

[0020] like figure 2 As shown, the thin-film solar cell of an embodiment of the present invention has a structure of: glass substrate layer 11 / Mo back electrode layer 10 / P-type copper indium gallium selenide thin film layer 9 / N-type copper indium gallium selenide buffer layer 8 / P + Layer 7 / P-type amorphous silicon layer 6 / I-type amorphous silicon layer 5 / N-type amorphous silicon layer 4 / N + Layer 3 / ZnO:Al layer 2 / front glass lining layer 1, sunlight enters from the front glass lining layer 1, and passes through ZnO:Al layer 2, N + Layer 3, N-type amorphous silicon layer 4, I-type amorphous silicon layer 5, P-type amorphous silicon layer 6, P + Layer 7 and N-type CIGS buffer layer 8 are then completely absorbed by P-type CIGS thin film layer 9 .

[0021] Among them, the thickness of the amorphous silicon P-I-N junction layer is 100nm, and the thickness ratio of the P-type amorphous silicon layer 6, the I-type amorphous silicon layer 5 and the N-type amorphous silicon layer ...

Embodiment 2

[0023] The structure of the thin film solar cell of this embodiment is the same as the structure of the thin film solar cell of Embodiment 1, see the structure figure 2 As shown, its structure is: glass substrate layer 11 / Mo back electrode layer 10 / P-type copper indium gallium selenide thin film layer 9 / N-type copper indium gallium selenide buffer layer 8 / P + Layer 7 / P-type amorphous silicon layer 6 / I-type amorphous silicon layer 5 / N-type amorphous silicon layer 4 / N + Layer 3 / ZnO:Al layer 2 / front glass lining layer 1, sunlight enters from the front glass lining layer 1, and passes through ZnO:Al layer 2, N + Layer 3, N-type amorphous silicon layer 4, I-type amorphous silicon layer 5, P-type amorphous silicon layer 6, P + Layer 7 and N-type CIGS buffer layer 8 are then completely absorbed by P-type CIGS thin film layer 9 .

[0024] The difference is: the thickness of the amorphous silicon P-I-N junction layer is 360nm, and the thickness ratio of the P-type amorphous silicon ...

Embodiment 3

[0026] The structure of the thin film solar cell of this embodiment is the same as the structure of the thin film solar cell of Embodiment 1, see the structure figure 2 As shown, its structure is: glass substrate layer 11 / Mo back electrode layer 10 / P-type copper indium gallium selenide thin film layer 9 / N-type copper indium gallium selenide buffer layer 8 / P + Layer 7 / P-type amorphous silicon layer 6 / I-type amorphous silicon layer 5 / N-type amorphous silicon layer 4 / N + Layer 3 / ZnO:Al layer 2 / front glass lining layer 1, sunlight enters from the front glass lining layer 1, and passes through ZnO:Al layer 2, N + Layer 3, N-type amorphous silicon layer 4, I-type amorphous silicon layer 5, P-type amorphous silicon layer 6, P + Layer 7 and N-type CIGS buffer layer 8 are then completely absorbed by P-type CIGS thin film layer 9 .

[0027] The difference is: the thickness of the amorphous silicon P-I-N junction layer is 200nm, and the thickness ratio of the P-type amorphous silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com