Pure natural raw juice of full banana fruits and production method thereof

A pure natural, banana technology, applied in the direction of food science, etc., can solve the problems of high juice yield and clarity, low juice yield, difficult to remove the astringency of juice, etc., to improve the juice yield and clarity, high conversion rate of raw materials, Good color protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

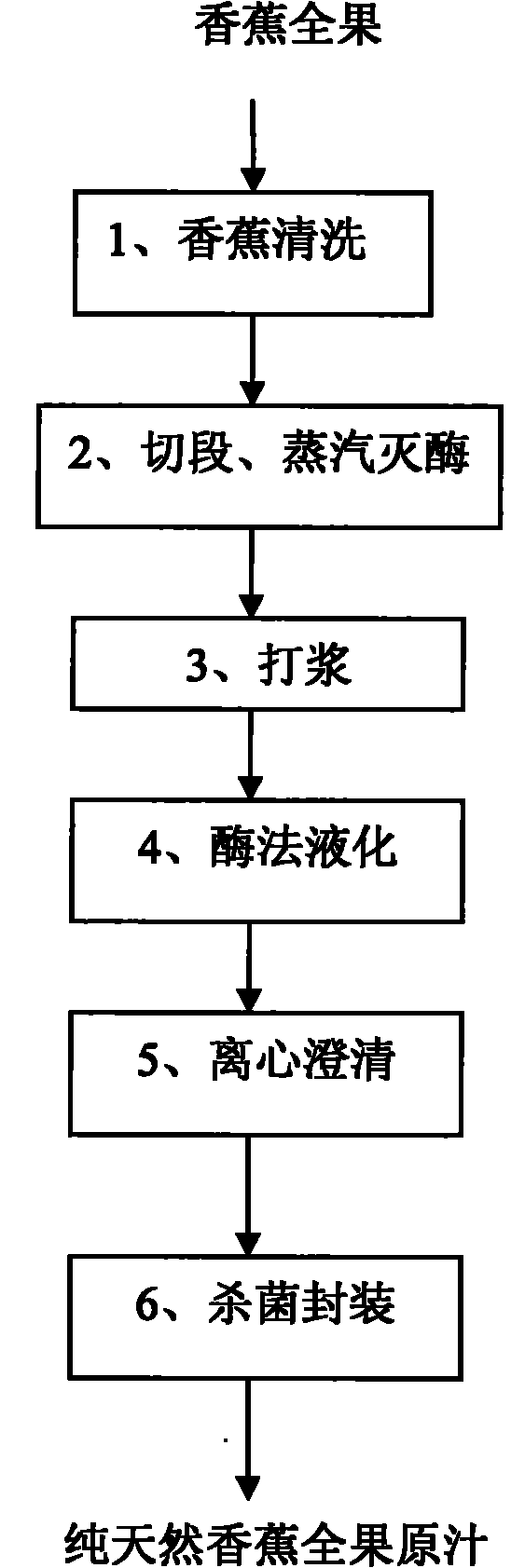

[0027] 1. Preparation method:

[0028] 1) Banana whole fruit cleaning: choose fully ripe and non-rotten bananas as raw materials, use running water to clean the dirt on the surface of the banana peel, and cut off the banana stem and fruit handle.

[0029] 2) Segment inactivation of enzymes: Take 100KG of the above-mentioned washed whole bananas without peeling, cut into small pieces about 3-4cm long, and heat them with steam at a temperature of 100°C for 6 minutes.

[0030] 3) Beating: The enzyme-inactivated banana fruit does not need to be cooled, and it is beaten to a muddy material with a beater at a speed of 2000-5000r / min to obtain a 100KG slurry.

[0031] 4) Enzymatic liquefaction:

[0032] Add the compound enzyme preparation obtained by compounding 100 ml of pectinase Ultra SP-L and 100 ml of cellulase, and react at 40-60°C for 50-70min, stirring at a speed of 150r / min; after the reaction, the temperature is raised to Maintain above 90°C for 3-5 minutes to inactivate ...

Embodiment 2

[0042] 1. Preparation method:

[0043] Its preparation method is substantially the same as Example 1, except that:

[0044] 1) Segmentation to kill enzymes: After cutting the whole banana with skin into segments, heat it with steam at 130°C for 1 minute;

[0045] 2) Enzymatic liquefaction: The compound enzyme preparation is 20ml of pectinase and 70ml of cellulase.

[0046] Obtain 75.4L of original banana juice.

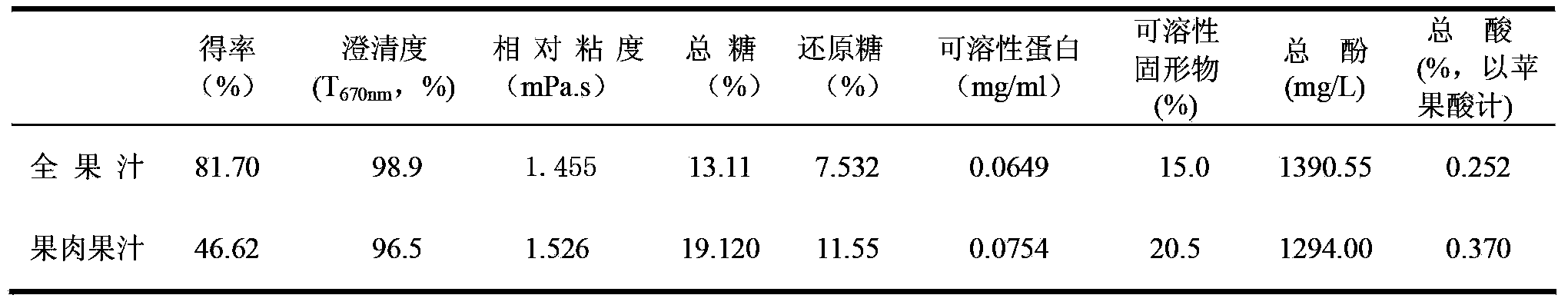

[0047] 2. The relevant physical and chemical indicators / data of the banana whole fruit juice obtained by the above method are as follows:

[0048] Juice yield: 75.4ml original juice / 100g fresh fruit

[0049] Clarity: 96.5%

[0050] Soluble solid content ≥ 15% acidity (pH4.0)

[0051] Relative viscosity: 1.594mPa.s

[0052] Sensory indicators: bright yellow color, clear and transparent, refreshing taste, with typical aroma of banana.

Embodiment 3

[0054] 1. Preparation method:

[0055] Its preparation method is substantially the same as Example 1, except that:

[0056] Enzymatic liquefaction: The compound enzyme preparation is 80 ml of pectinase, 70 ml of cellulase, and 30 grams of α-amylase.

[0057] Obtain 81.7L of original banana juice.

[0058] 2. The relevant physical and chemical indicators / data of the banana whole fruit juice obtained by the above method are as follows:

[0059] Juice yield: 81.7ml original juice / 100g fresh fruit

[0060] Clarity: 98.9%

[0061] Relative viscosity: 1.455mPa.s

[0062] Soluble solid content ≥ 15% acidity (pH4.0)

[0063] Sensory indicators: bright yellow color, clear and transparent, refreshing taste, with typical aroma of banana.

[0064] 4. Relevant experimental data:

[0065] 1. Flavor of banana whole fruit juice:

[0066] During the processing of fruit juice, thermal processing steps such as enzyme elimination, enzymolysis and sterilization are generally required. High...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com