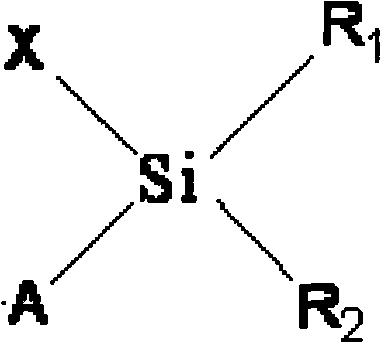

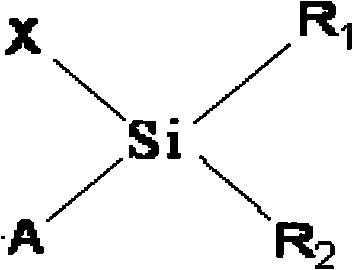

Supported metallocene catalyst and preparation and application thereof

A technology of metallocene catalysts and metallocene compounds, which is applied in physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, organic chemistry, etc., and can solve ligand shedding, complex reactions, and reduced catalyst activity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

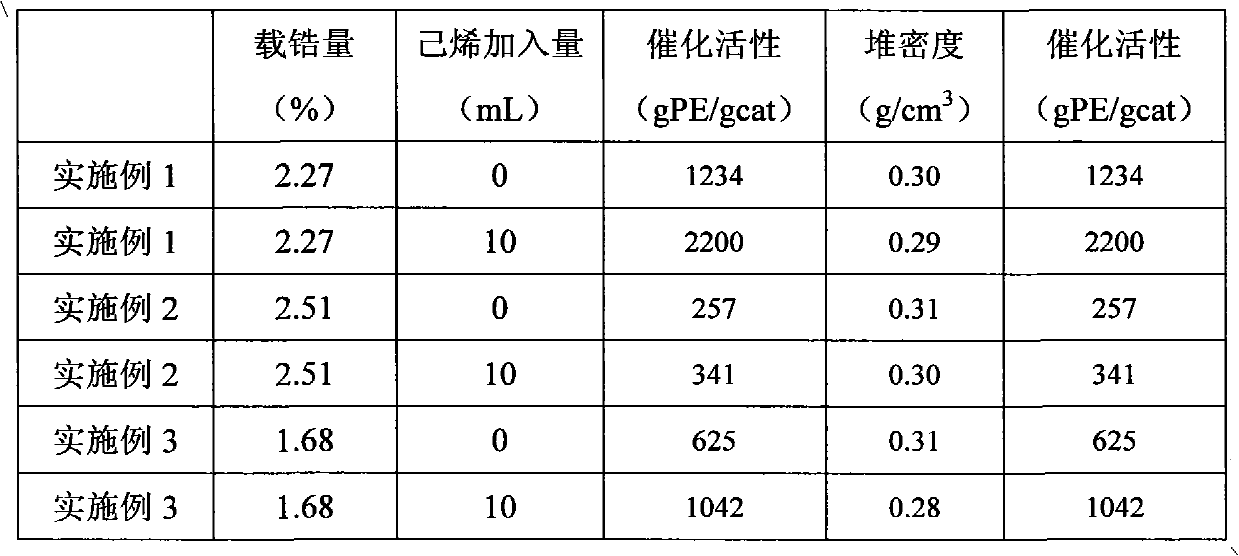

Embodiment 1

[0031] All operations are carried out under anhydrous and oxygen-free conditions, and the solvents used need to be dehydrated and deoxygenated.

[0032] 1. Dimethylvinylchlorosilane modified SiO 2

[0033] The silica gel was activated at 600°C for 6h. Activated 1g SiO 2 Uniformly disperse in 50mL dry toluene solution, add 0.02mL dimethylvinylchlorosilane dropwise at room temperature, start heating after dropwise addition, react at 75°C for 8h, stop stirring. Stand still to drain the upper layer of toluene solution, then wash with dry hexane several times, and obtain white SiO after drying. 2 Solid particles. Determination of SiO by titration method 2 Surface hydroxyl content, SiO 2 The conversion rate of surface hydroxyl groups is shown in Table 1.

[0034] 2. Preparation of ethyl bridged dichlorobisindenyl zirconium supported catalyst

[0035] The functionalized SiO obtained in the previous step 2 Disperse evenly in 50mL dry toluene solution, add 0.041mol MAO solutio...

Embodiment 2

[0040] All operations are carried out under anhydrous and oxygen-free conditions, and the solvents used need to be dehydrated and deoxygenated.

[0041] 1. SiO modified with dimethylallyl chlorosilane 2

[0042] The silica gel was activated at 600°C for 6h. Activated 1g SiO 2 Disperse evenly in 50mL dry toluene solution, add 0.02mL dimethylallyl chlorosilane dropwise at room temperature, start heating after dropwise addition, react at 50°C for 24h, stop stirring. Stand still to drain the upper layer of toluene solution, then wash with dry hexane several times, and obtain white SiO after drying. 2 Solid particles. Determination of SiO by titration method 2 Surface hydroxyl content, SiO 2 The conversion rate of surface hydroxyl groups is shown in Table 1.

[0043] 2. Ethyl bridged dichlorobisindenyl zirconium supported catalyst

[0044] The test procedure is the same as in Example 1. Arsenazo III spectrophotometry was used to measure the amount of zirconium loaded on th...

Embodiment 3

[0048] All operations are carried out under anhydrous and oxygen-free conditions, and the solvents used need to be dehydrated and deoxygenated.

[0049] 1. Methylphenylvinylchlorosilane Modified SiO 2

[0050] The silica gel was activated at 600°C for 6h. Activated 1g SiO 2 Disperse evenly in 50mL dry toluene solution, add 0.26mL methylphenylvinylchlorosilane dropwise at room temperature, start heating after the dropwise addition, react at 75°C for 8h, and stop stirring. Stand still to drain the upper layer of toluene solution, then wash with dry hexane several times, and obtain white SiO after drying. 2 Solid particles. Determination of SiO by titration method 2 Surface hydroxyl content, SiO 2 The conversion rate of surface hydroxyl groups is shown in Table 1.

[0051] 2. Ethyl bridged dichlorobisindenyl zirconium supported catalyst

[0052] The test procedure is the same as in Example 1. Arsenazo III spectrophotometry was used to measure the amount of zirconium load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com