Method and device for comprehensively recycling waste printed circuit boards

A circuit board and waste printing technology, applied in the field of environmental engineering, can solve the problem of low comprehensive utilization rate of the treatment method, and achieve the effects of simple structure, easy enlargement and strong process adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

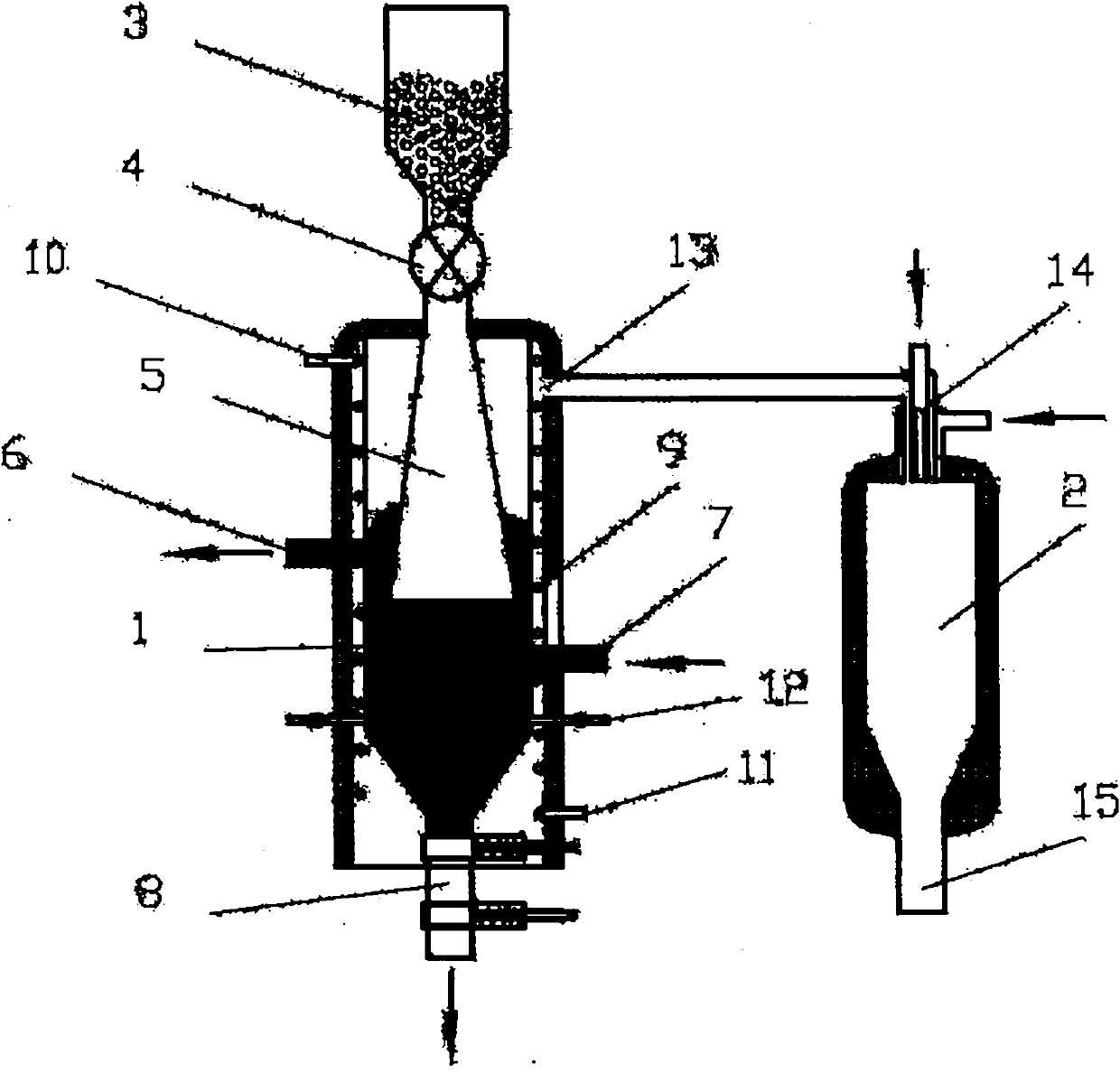

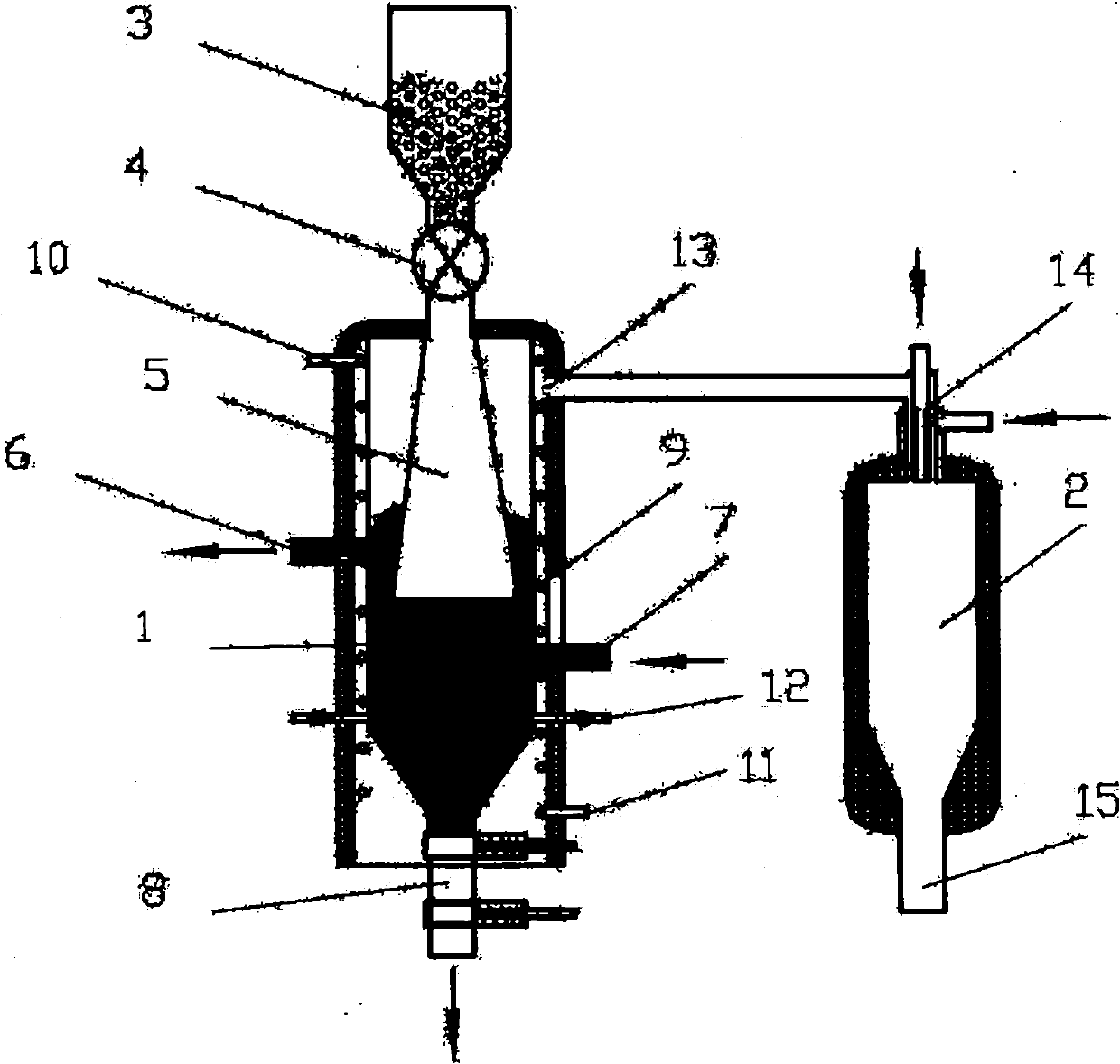

Image

Examples

Embodiment 1

[0024] A method for comprehensive recycling of waste printed circuit boards, comprising the following steps:

[0025] (1) Gasification of waste printed circuit boards: the waste printed circuit boards enter the molten salt reaction furnace after being crushed. The molten salt is a binary salt, which includes 71% Na 2 CO 3 and 29%K 2 CO 3 , gasification at 700-900°C to obtain gasification residues and gas products containing a large amount of tar. The gasification residues are stratified in the molten salt, and are discharged from the molten salt reaction furnace from different positions of the molten salt reaction furnace for recycling respectively;

[0026](2) Removal of bromine-containing pollutants: when waste printed circuit boards are gasified in molten salt, Br in waste printed circuit boards is mainly released in the form of HBr, and the released acidic HBr is immediately absorbed by alkaline molten salt, At the same time, a small amount of bromine-containing organic...

Embodiment 2

[0039] The molten salt in the molten salt reaction furnace of this embodiment is a ternary salt, which consists of the following components:

[0040] 39% Li 2 CO 3 -38.5%K 2 CO 3 -22.5% Rb 2 CO 3 ;

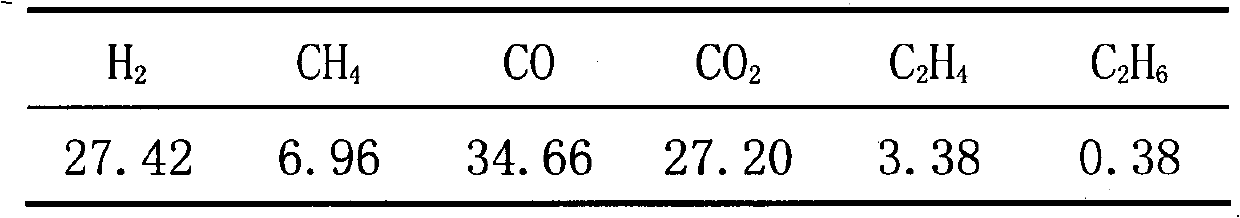

[0041] The gas volume ratio of oxygen-enriched air, gaseous product, and water vapor is=1:0.6:1; get H at the same time 2 Syngas / CO ratio of 0.9.

[0042] Other structures of this embodiment are the same as those of Embodiment 1, and will not be described in detail here.

Embodiment 3

[0044] The molten salt in the molten salt reaction furnace of this embodiment is a ternary salt, which consists of the following components:

[0045] 43.5% Li 2 CO 3 -31.5% Na 2 CO 3 -25%K 2 CO 3 ;

[0046] The gas volume ratio of oxygen-enriched air, gaseous product, and water vapor is=1:0.7:3; simultaneously obtain H 2 Syngas / CO ratio of 1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com