Ceramic brick manufacturing process with concave-convex polished in-glaze decoration

A traction wheel and netting machine technology, applied in the field of architectural ceramics, can solve the problems of low popularity or usage, old texture and atmosphere, lack of polished tiles, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

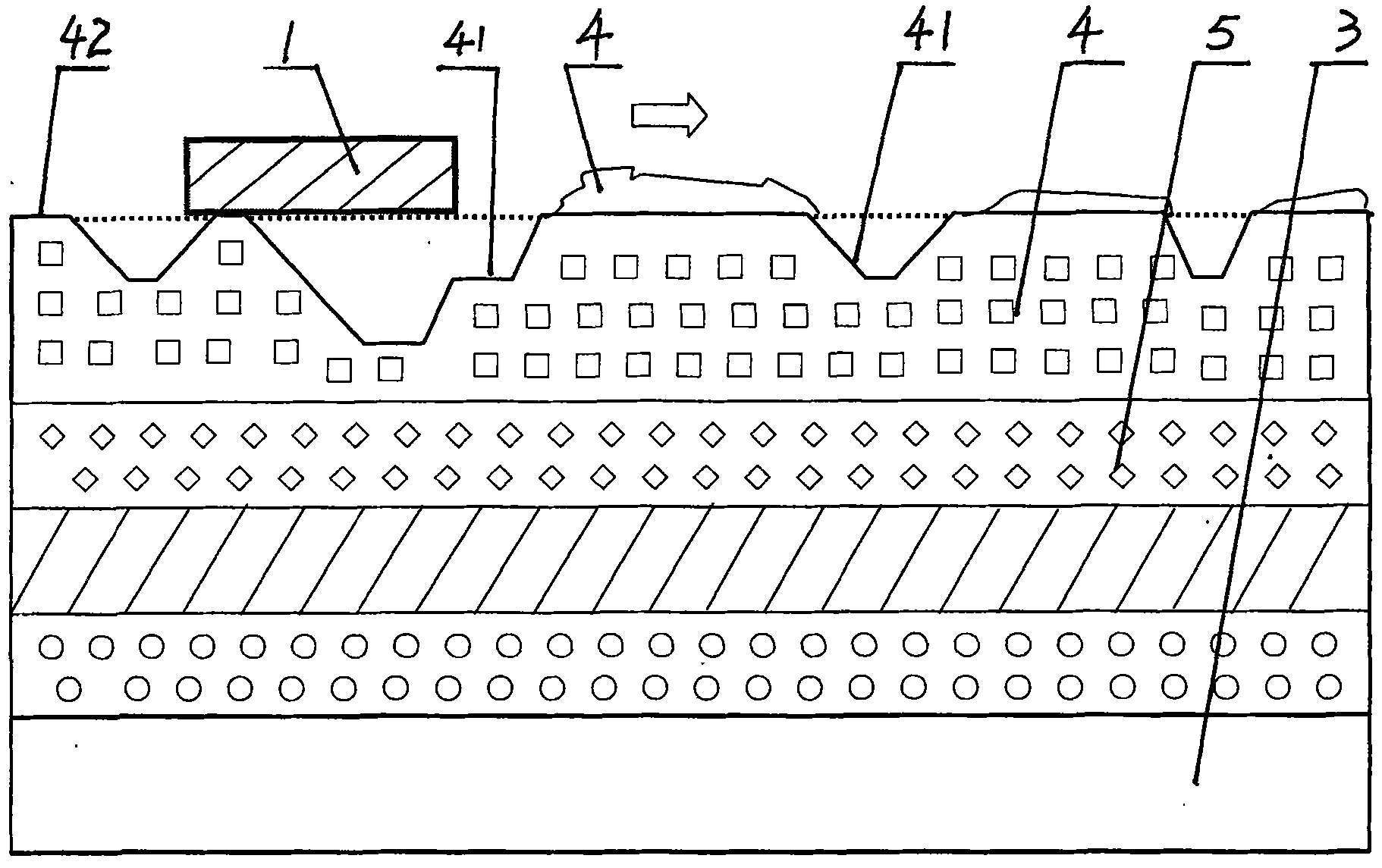

[0019] (1) Brick forming

[0020] The powder is pressed through a conventional molding die to produce adobes of specified specifications, and the thickness is required to be 10±0.3mm.

[0021] (2) Glaze printing

[0022] After the adobe is dried, spray a layer of primer on the surface of the adobe, then use screen printing to print twice according to the set pattern, and then use roller printing to print twice. The total number of printings is 4 times, and then Apply a layer of dry powder transparent glaze with a glaze thickness of 1.05mm. On this layer of transparent glaze, the pattern corresponding to the printed pattern is printed into a glaze layer with obvious concave and convex contours. The depth of the concave surface is 0.7-0.8mm in different shades.

[0023] (3) Brick firing

[0024] After the glazed and printed bricks are covered with a layer of ground slurry, they are sent to a roller kiln for firing at a high temperature of 1200 °C.

[0025] (4) glaze polishing...

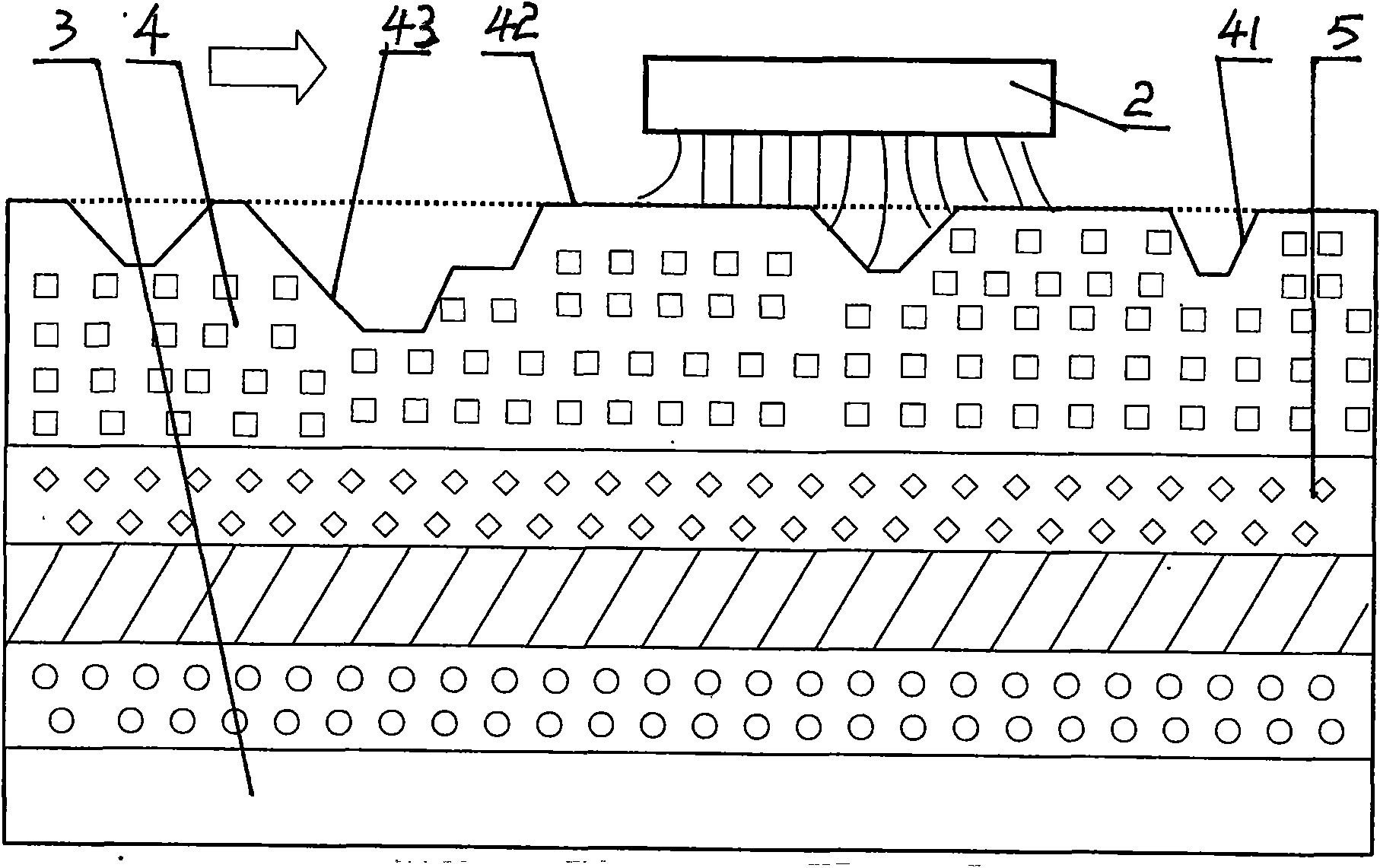

Embodiment 2

[0028] (1) Brick forming

[0029] The powder is pressed through a conventional molding die to produce adobes of specified specifications, and the thickness is required to be 11.5±0.3mm.

[0030] (2) Glaze printing

[0031] After the adobe is dried, spray a layer of primer on the surface of the adobe, and then use screen printing to print twice according to the set pattern, and then use screen printing to print three times. The total number of printings is 5 times, and then Apply a layer of dry powder transparent glaze with a thickness of 0.9mm. The transparent glaze on this layer is printed according to the pattern corresponding to the printed pattern to form a glaze layer with obvious concave and convex contours. The depth of the pit surface is 0.6-0.75mm.

[0032] (3) Brick firing

[0033] The bricks that have been glazed and printed are sent to the roller kiln for firing at a high temperature of 1220°C.

[0034] (4) glaze polishing

[0035] After the brick is fired, put...

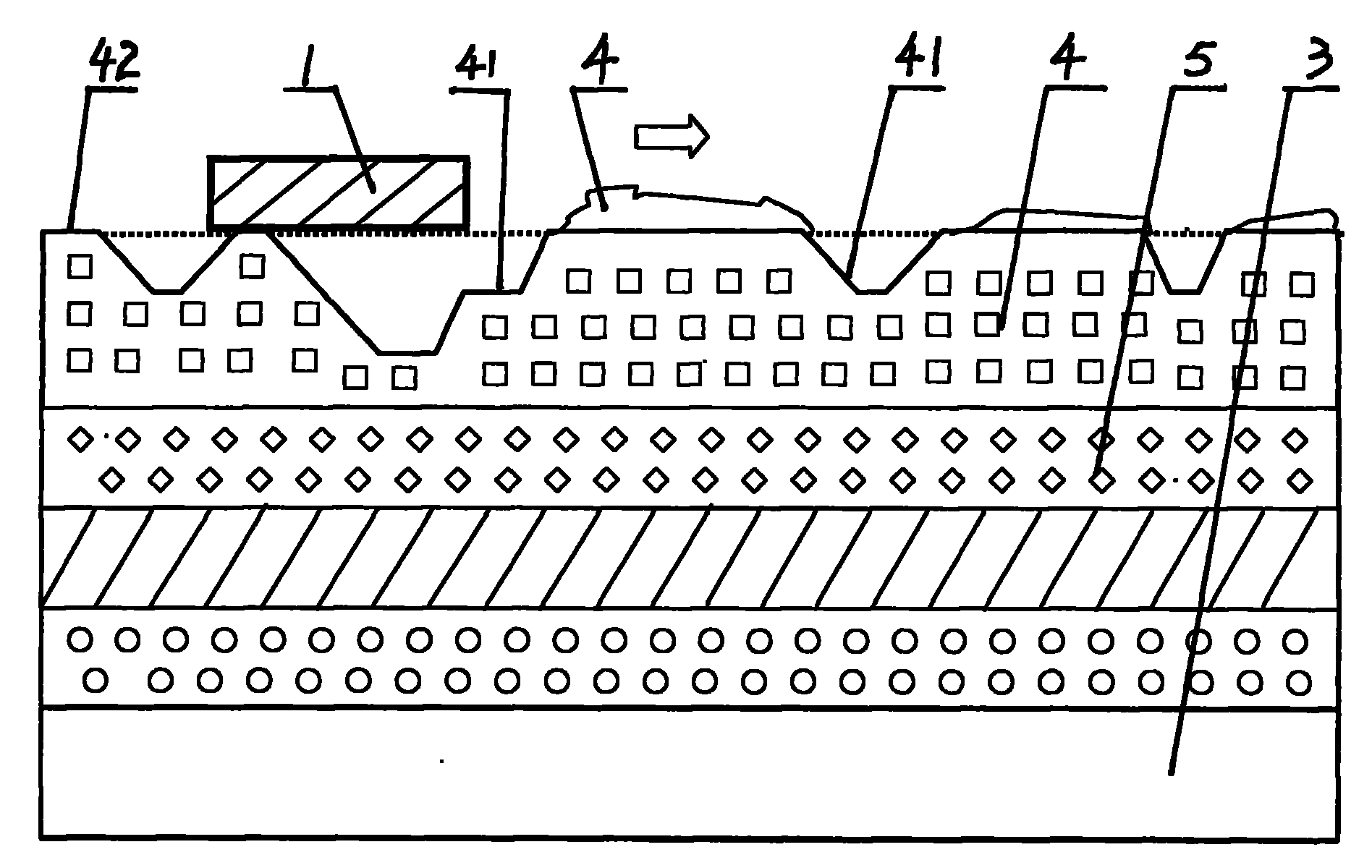

Embodiment 3

[0037] (1) Brick forming

[0038]Press the powder into a flat adobe of specified specifications through a conventional molding die, and the thickness is required to be 10±0.3mm.

[0039] (2) Glaze printing

[0040] After the adobe is dried, spray a layer of primer on the surface of the adobe, then use roller printing to print three times according to the set pattern, then spray a layer of transparent glaze, and then use roller printing to print twice. The total number of printings is 5 times, and then a layer of dry powder transparent glaze dry powder with a glaze layer thickness of 1.0mm is applied. The transparent glaze on this layer is printed into a glaze layer with obvious concave and convex contours according to the corresponding patterns of in-glaze color patterns. The depth of the pit surface varies from 0.6 to 0.7mm.

[0041] (3) Brick firing

[0042] The bricks that have been glazed and printed are sent to the roller kiln to be fired at a high temperature of 1230 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com