Harmonic micrometer/nanometre film thermal property test method

A nano-film and testing method technology, applied in the field of testing, can solve the problems that the film cannot be accurately measured at the same time, and the multiple thermophysical parameters of the nano-thick film cannot be measured, so as to reduce the influence of the end effect and the influence of radiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Various details involved in the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be pointed out that the described embodiments are only intended to facilitate the understanding of the present invention, and do not have any limiting effect on the present invention.

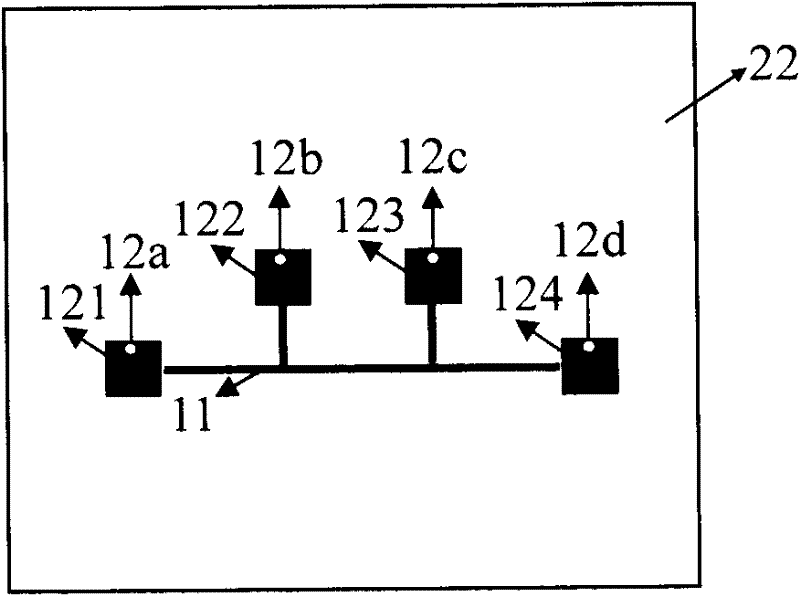

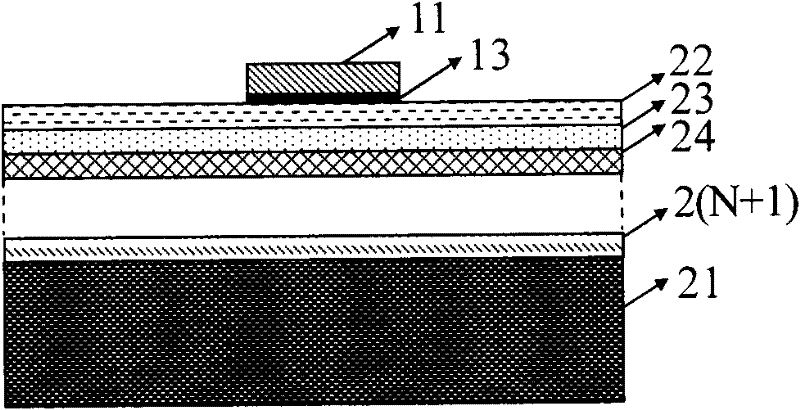

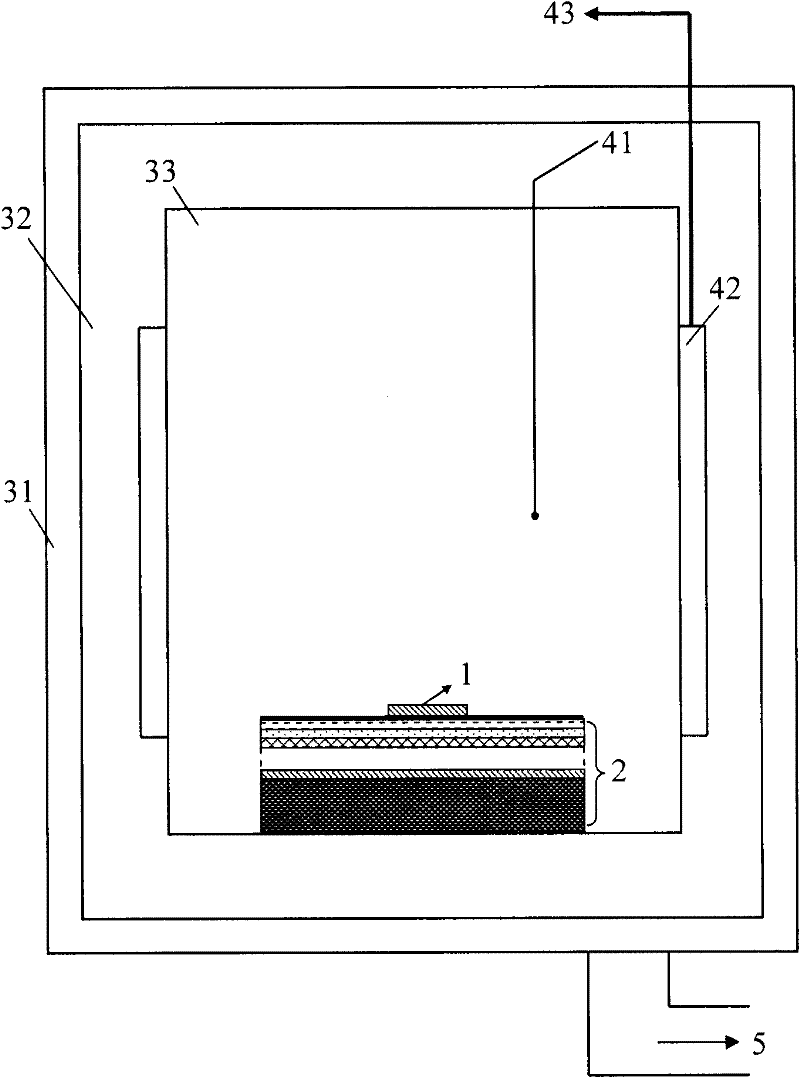

[0035] The present invention relates to a method for testing thermal properties of micro / nano thin films by means of harmonic method, which involves the technical scheme of using alternating current to heat micro metal detectors combined with harmonic detection technology to realize the detection of single / multi-layer micro / nano thin film structures on the substrate surface Simultaneous measurement of thermal conductivity and thermal diffusivity parameters. The steps to realize the thermophysical property testing method of the harmonic micro / nano thin film are as follows: ① Deposit a thin layer of metal 13 (Ti or Ge) on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com