Polybutylene terephthalate resin composition and thin molded article

A technology of polybutylene terephthalate and resin composition, which is applied in the field of polybutylene terephthalate resin composition and thin-walled molded products, and can solve the problems of reduced mechanical strength, less warping deformation, The lack of fluidity of the composition, etc., to achieve the effect of excellent melt fluidity, excellent mechanical strength and impact strength, and less warping deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The composition of the present invention can be easily prepared using equipment and methods commonly used in conventional resin composition preparation methods. For example, any of the following methods can be used: after mixing the ingredients, they are mixed and extruded by a single-screw or twin-screw extruder to prepare granules, and then shaped; Mixing for molding, the method of obtaining a molded product with the target composition after molding; the method of directly feeding one or more than two kinds of components to the molding machine, etc. In addition, a method of mixing and adding a part of the resin component in the form of a fine powder with the other components is a preferable method because it enables these components to be uniformly blended. The fluidity of the resin composition of the present invention can be reflected by the melt viscosity at a certain piston flow shear rate as an index. For example, according to ISO11443 at a temperature of 260°C a...

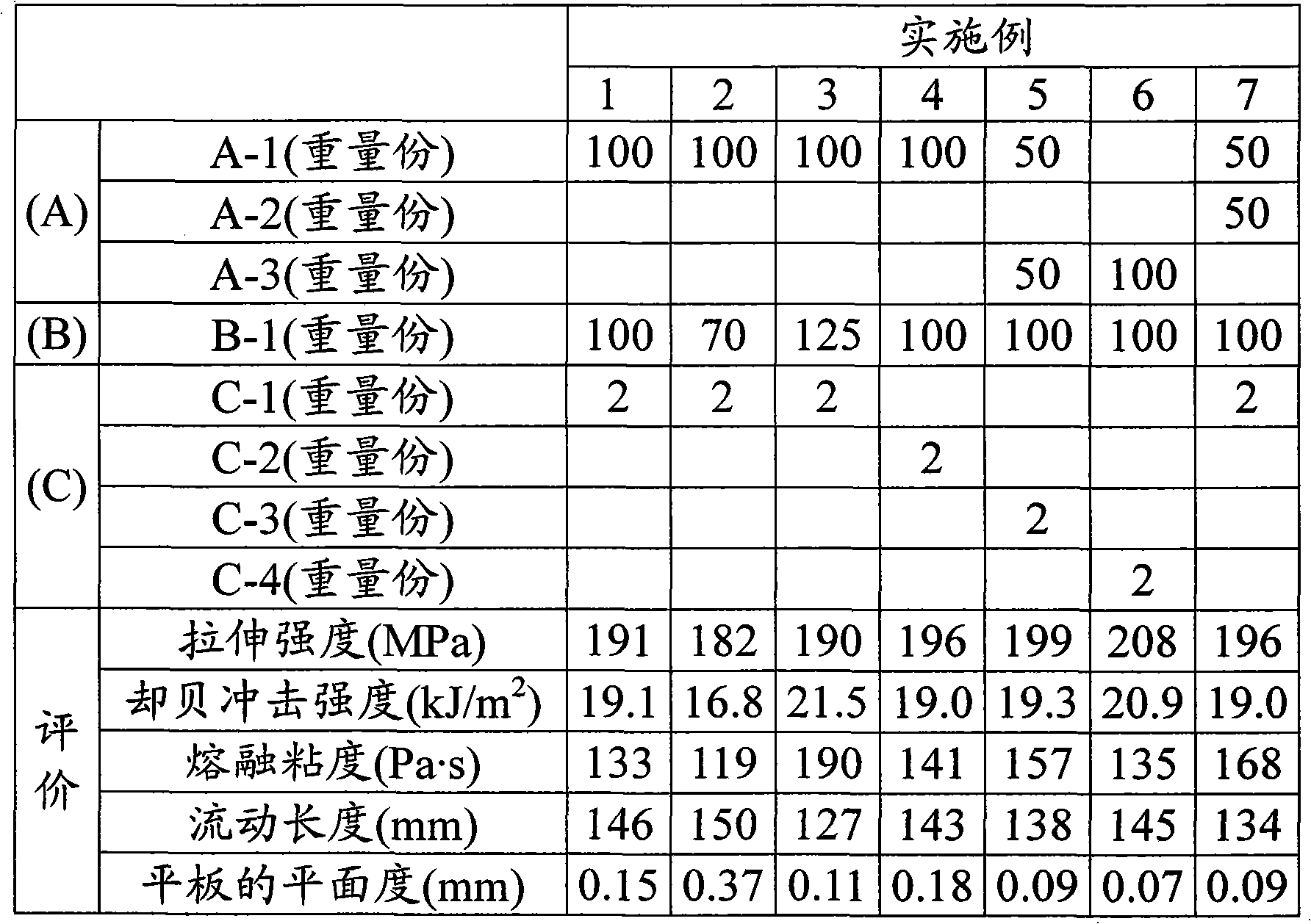

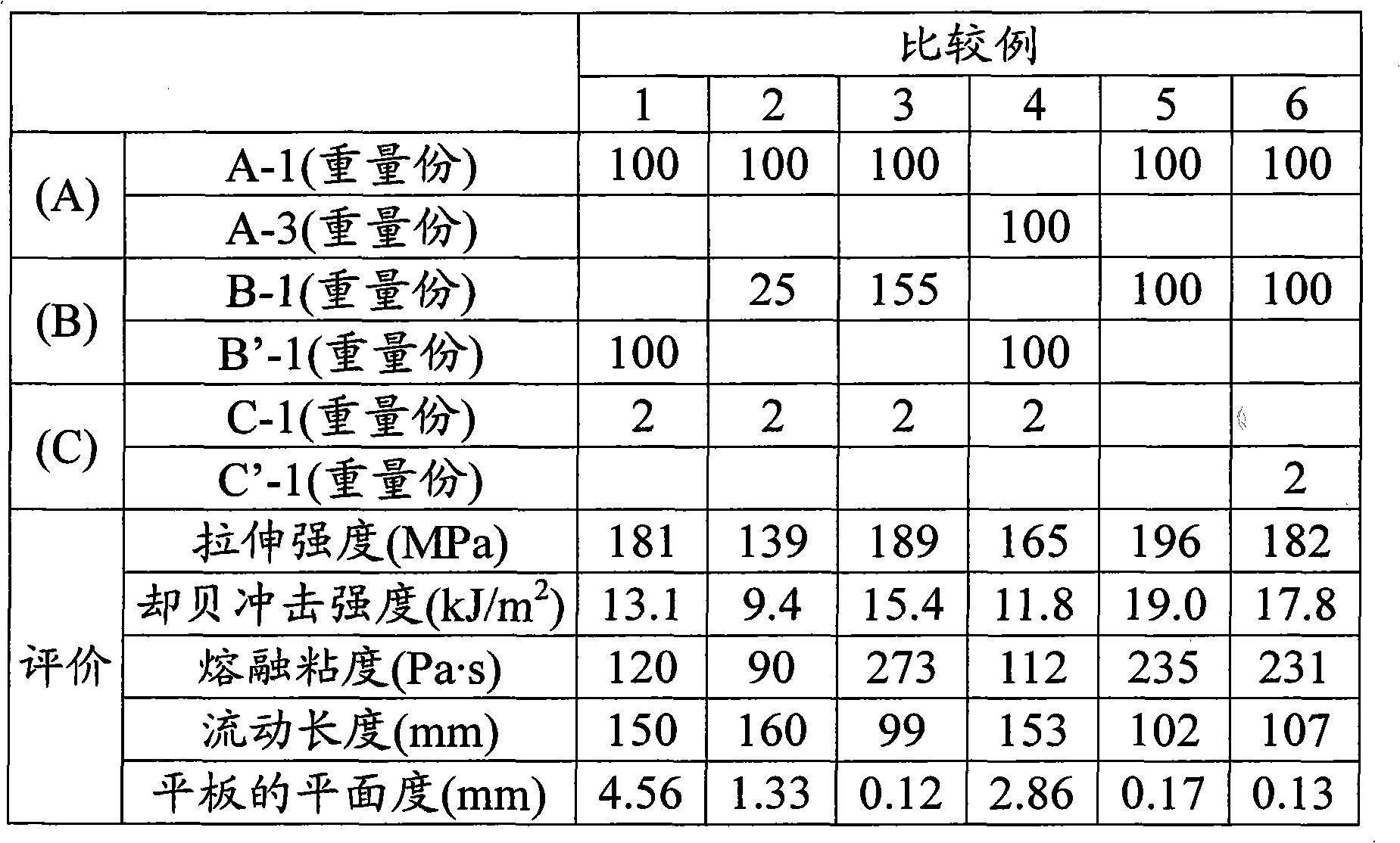

Embodiment 1~7、 comparative example 1~6

[0050] Dry mix each resin composition according to the mixing ratio shown in Table 1 and 2, and use a 30mm A twin-screw extruder (manufactured by The Japan Steel Works, LTD.) with the same screw was melt-mixed at a cylinder set temperature of 250° C., and then pelletized to produce test pieces and perform various evaluations. The results are shown in Tables 1 and 2.

[0051] In addition, the details of the components used and the measuring method of physical property evaluation are as follows.

[0052] (A) polyester resin

[0053] (A-1) Polybutylene terephthalate (intrinsic viscosity IV=0.69 dL / g, manufactured by WinTech Polymer Ltd.)

[0054] (A-2) Isophthalic acid-modified polyethylene terephthalate (12.0 mol % isophthalic acid modified, intrinsic viscosity IV=0.80 dL / g, manufactured by Bell Polyester Products, Inc.)

[0055] (A-3) Isophthalic acid modified polybutylene terephthalate (intrinsic viscosity IV=0.65dL / g)

[0056] In the reaction of terephthalic acid and 1,4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| flow length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com