Method for producing coated paper

A manufacturing method and technology of coated paper, applied in the field of coated paper manufacturing, can solve problems such as insufficient resistance to damage on the surface of feeding rollers, and achieve white paper with excellent gloss, less ink unevenness, and surface excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

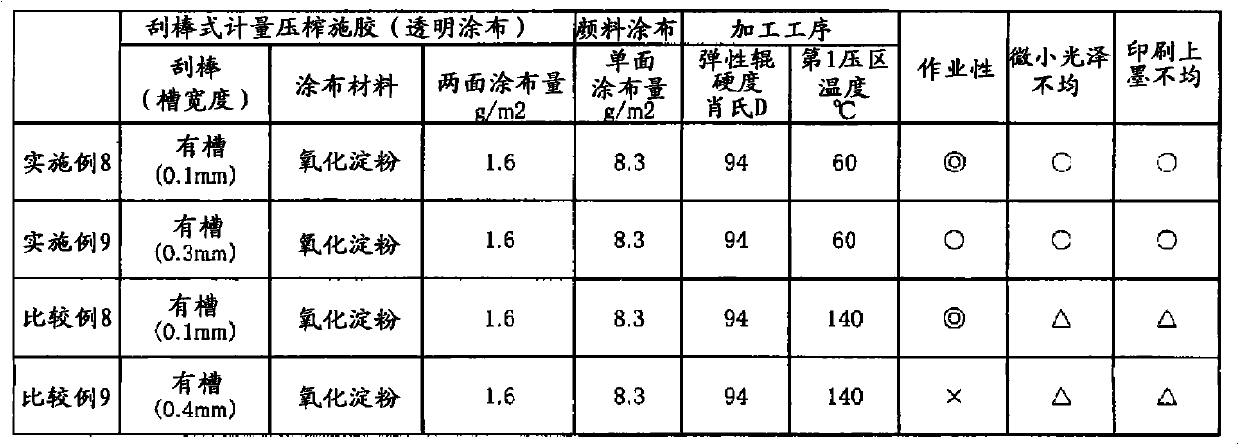

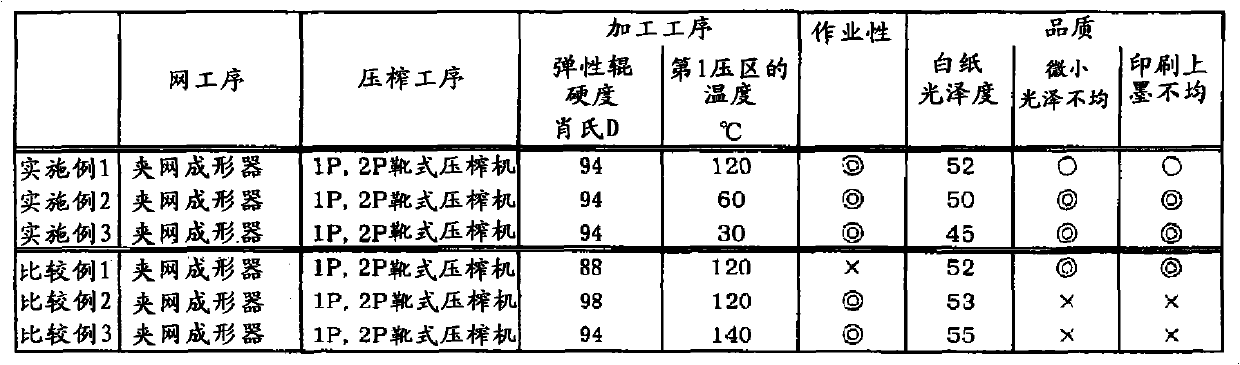

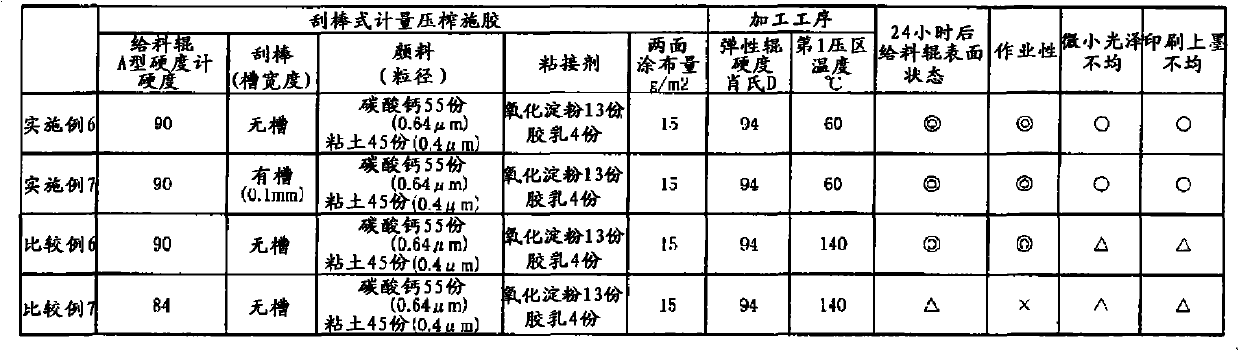

experiment example 1

[0081]

[0082] (1) Glossiness of white paper

[0083] According to JISP-8142, it measures at an angle of 75 degrees.

[0084] (2) High-speed operability

[0085] The workability during high-speed operation is based on the viewpoint that paper breakage is less likely to occur in the press section, the occurrence of mist during coating is less, the occurrence of shrinkage lines during calendering is less, and the durability of the elastic roll is high. 4 grades were evaluated.

[0086] ◎=very good, ○=good, △=slightly bad, ×=poor

[0087] (3) Minor gloss unevenness

[0088] The minute gloss unevenness of the final product was visually evaluated on the following four scales.

[0089] ◎=none, ○=almost none, △=slightly present, ×=extremely uneven gloss

[0090] (4) Uneven ink filling

[0091] Using a Roland sheet-fed printing machine (4 colors), use printing ink (Hy-UnityM manufactured by Toyo Ink) in the order of blue→red→yellow→black at a printing speed of 8000 sheets / min...

Embodiment 1

[0094] To the pulp liquid composed of 30 parts of old paper pulp and 70 parts of LBKP, light calcium carbonate was added as a filler so that the ash content in the paper reached 11%, and 3 parts of cationized starch was added as an internal paper strength agent to adjust the paper quality. material.

[0095] Use this paper stock, with the papermaking speed of 1600m / min roll and scraper former type paper machine, use 2 tandem shoe presses in the press section (press line pressure 1000kN / m, transmission The belt is in contact with the wire side of the paper of the second station), the wet paper is squeezed and dried, and the dried base paper is made into paper, and then the solid content is Concentration of 6% oxidized starch solution on both sides with 1.6g / m 2 Coated and dried to obtain 45.6g / m 2 of groundwood-containing (medium) coated base paper.

[0096] Next, 4.5 parts of oxidized starch and 8.2 parts of carboxy-modified styrene-butadiene copolymer latex were mixed with...

Embodiment 2

[0100] Coated paper was produced in exactly the same manner as in Example 1 above, except that the surface temperature of the metal roll in the first nip was changed to 60° C. in the processing step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com