Rust-removing cleaning device for ultrasonic pulse water jet pipe wall

A cleaning device and ultrasonic technology, applied in cleaning methods and appliances, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as low production efficiency, low processing quality, and low efficiency, and achieve reduced operation and maintenance costs, Effect of improving energy conversion efficiency and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings and embodiments.

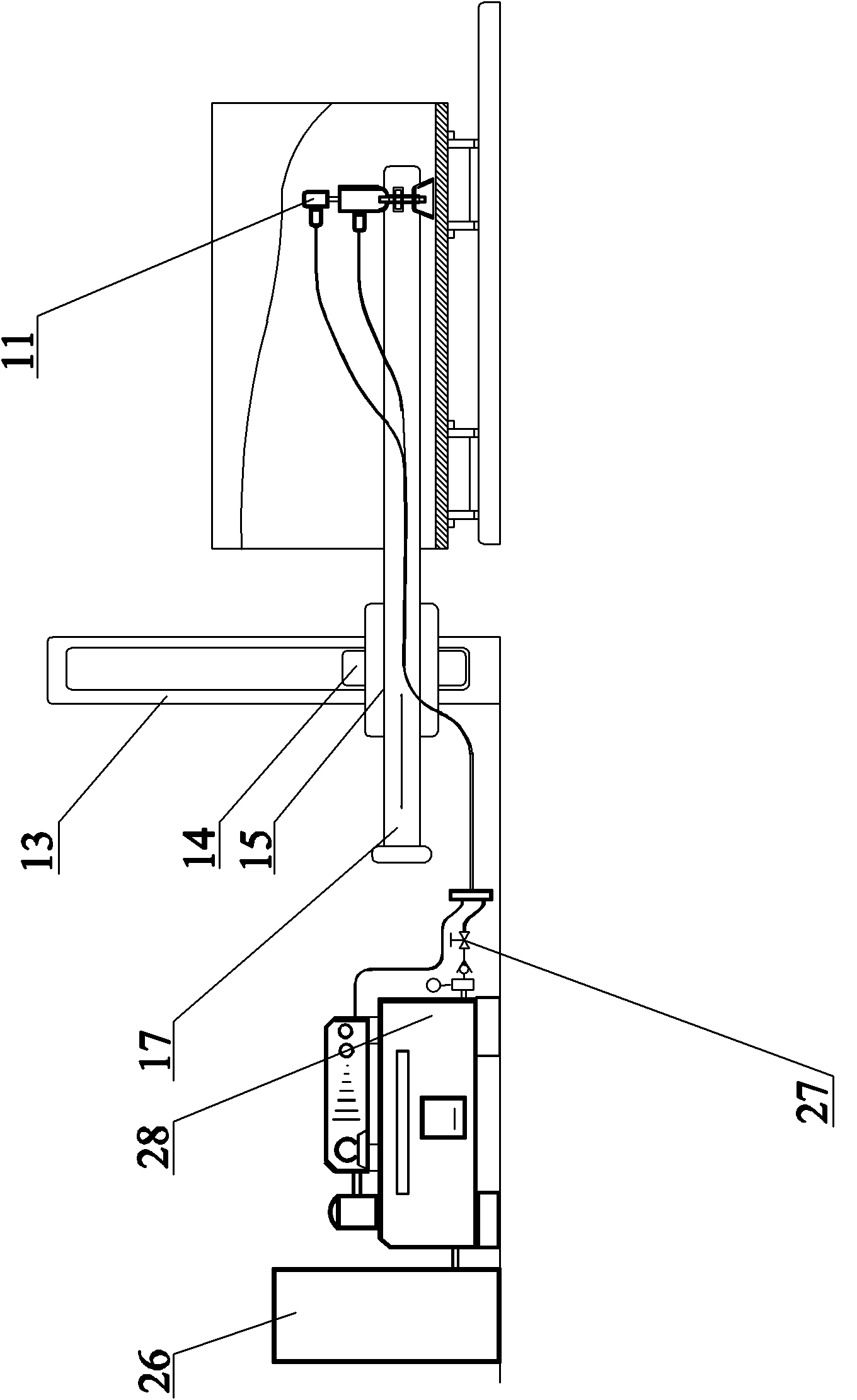

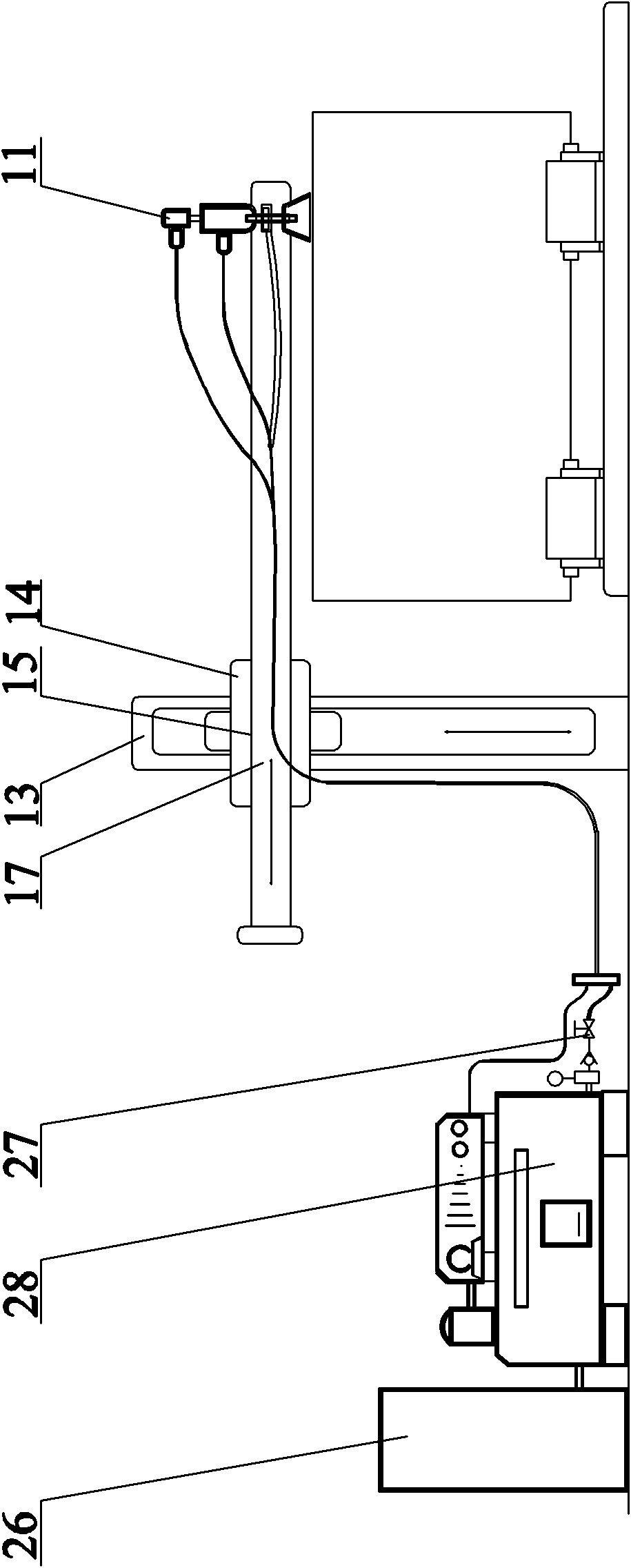

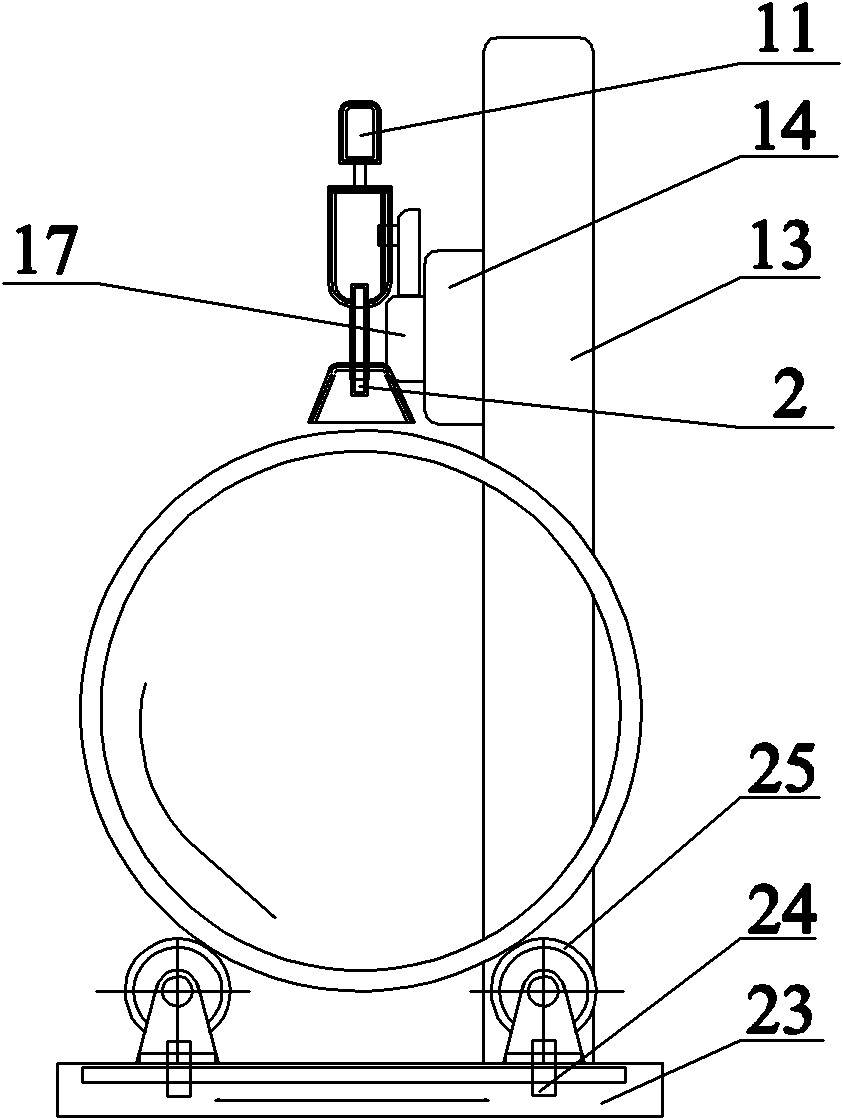

[0026] Such as figure 1 Shown: The ultrasonic pulse water jet pipe wall derusting and cleaning device includes a vortex pulse resonance jet nozzle mechanism, a translational lifting rail mechanism, a high-pressure water supply mechanism and an ultrasonic supply mechanism, including a vortex pulse resonance jet nozzle mechanism installed on a translational lifting rail mechanism Above, the high-pressure water supply mechanism and the ultrasonic supply mechanism are respectively connected with the high-pressure water input end and the ultrasonic wave input end of the vortex pulse resonance jet nozzle mechanism. Among them, the high-pressure water supply mechanism is composed of water tank 26, high-pressure pump 29, pressure regulating valve 27, high-pressure water delivery hose 30 and other components; the ultrasonic supply mechanism is composed of ultrasonic gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com