Welding method of stainless steel composite board

A welding method and composite plate technology, applied to welding equipment, arc welding equipment, workpiece edge parts, etc., can solve the problems of deteriorating joint quality and easy cracks, and achieve the effect of improving welding quality and preventing embrittlement or cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

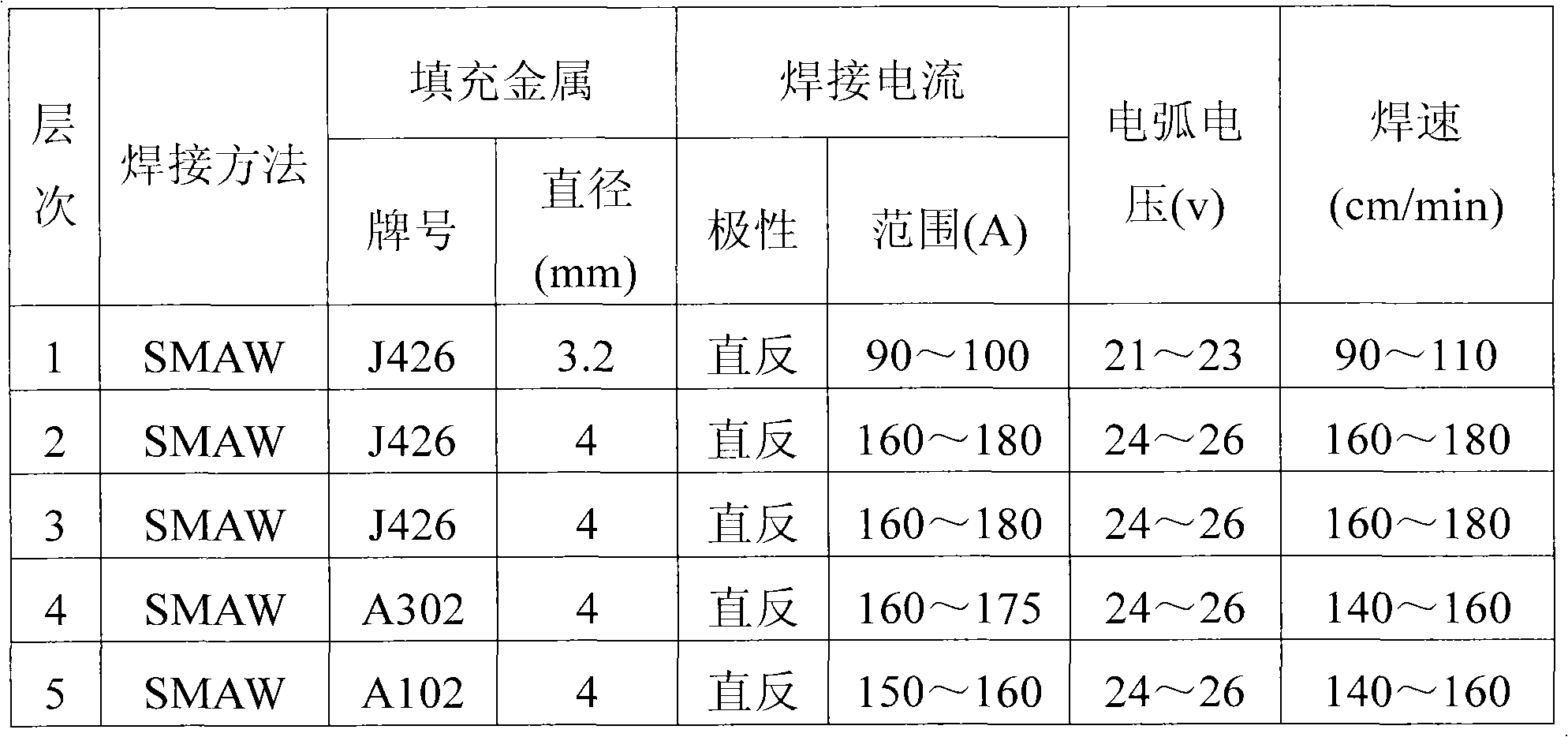

[0018] Hereinafter, embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

[0019] In the present invention, a stainless steel clad steel plate with 0Cr18Ni9 stainless steel as the composite material and low carbon structural steel as the base material is taken as an example to illustrate the embodiments of the present invention. The composite layer of the stainless steel clad plate is 0Cr18Ni9 stainless steel with a thickness of 2mm; the base layer is low carbon alloy steel Q235 with a thickness of 20mm. The welding of this stainless steel clad plate adopts the following steps.

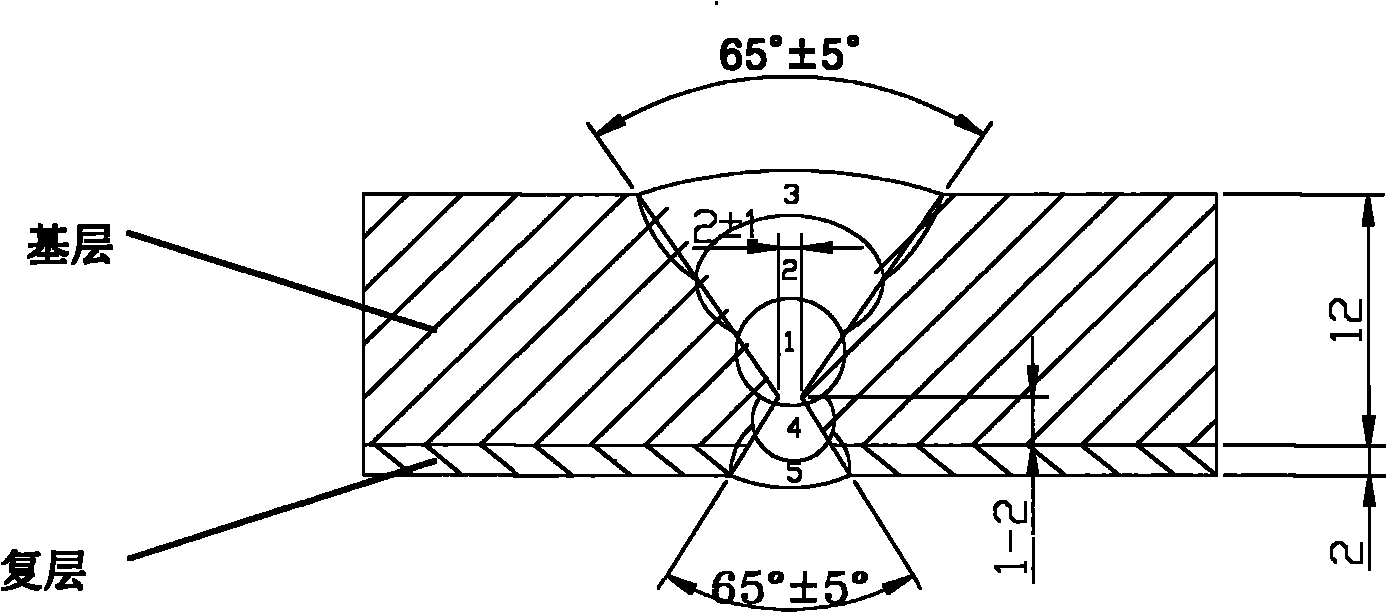

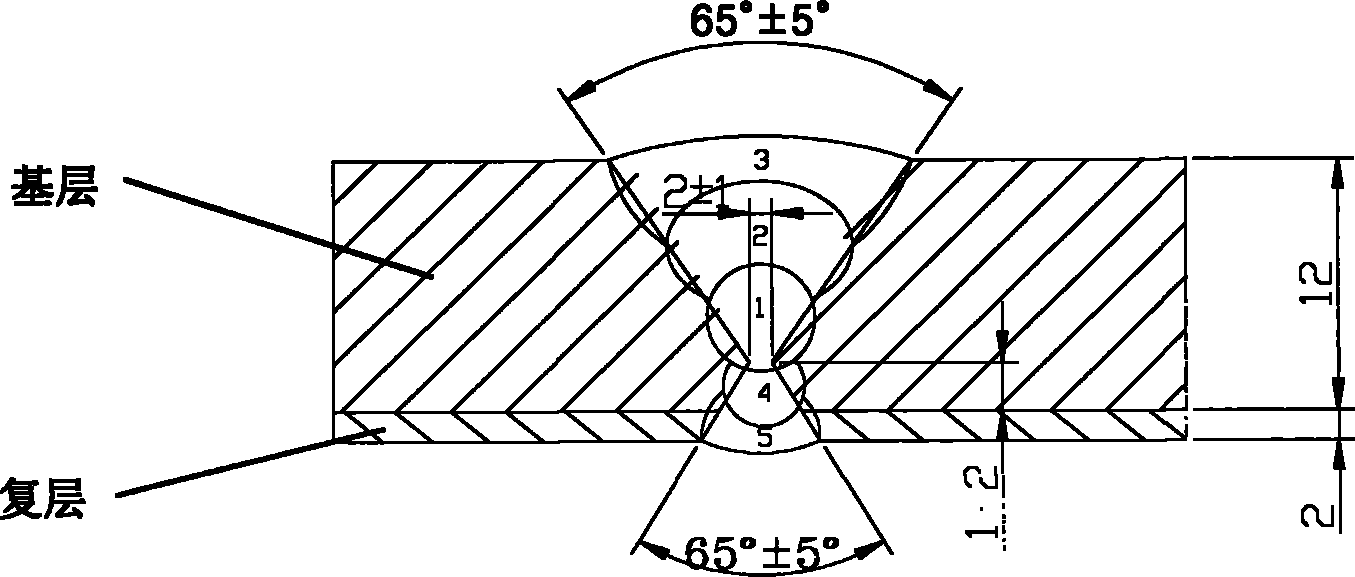

[0020] First, the welding end of the stainless steel clad plate is processed into an X-shaped bevel as shown in Figure 1 by plasma cutting, gas cutting and other mechanical processing methods. Wherein, the included angle between grooves is 65°±5°. The gap between the grooves of two relative stainless steel clad steel plates is 2±1mm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com