Magnetic-stability fluidized bed photocatalytic reactor and method for treating organic wastewater with difficult degradation thereby

A photocatalytic reactor and organic wastewater technology, which is applied in chemical instruments and methods, light water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of easy loss of active components, low photocatalytic activity, and photocatalytic quantum rate. Low-level problems, to achieve the effect of reducing the loss of active components, improving utilization efficiency, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

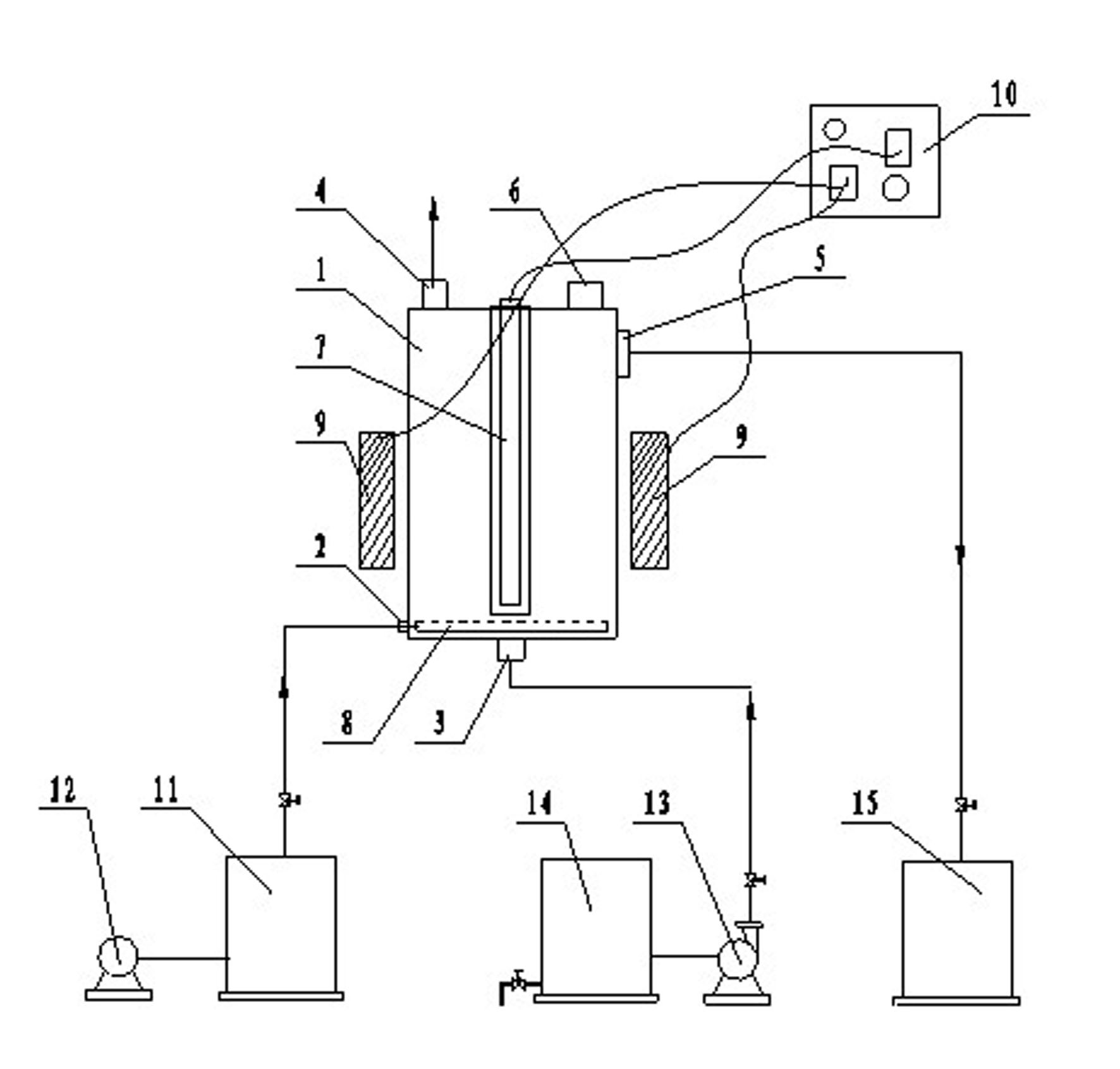

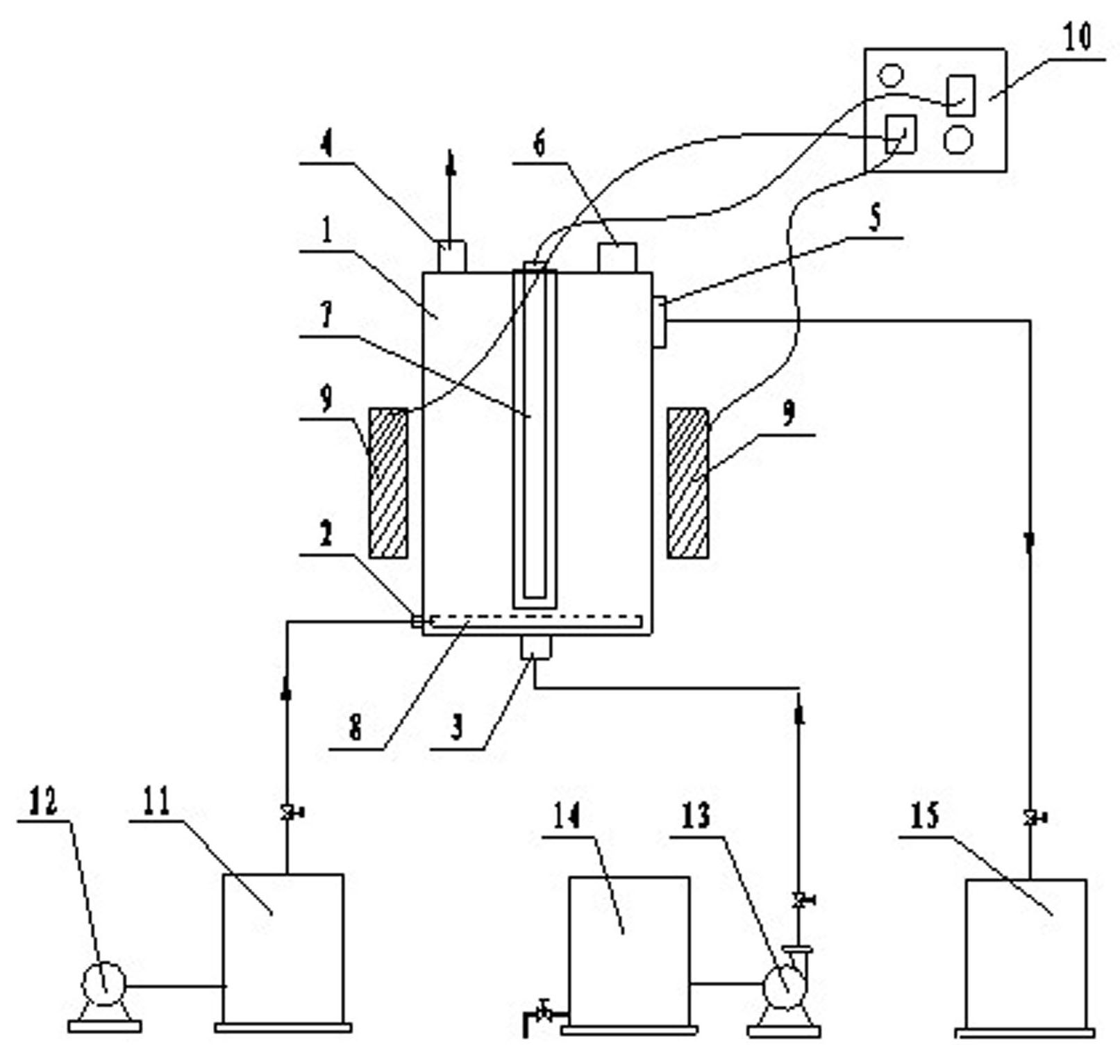

[0017] A magnetically stable fluidized bed photocatalytic reactor, comprising a cylindrical cylinder 1, a gas inlet 2 is provided on one side of the bottom of the cylindrical cylinder, a liquid inlet 3 is provided directly below, and a gas inlet is provided on the top of the cylindrical cylinder 1. Outlet 4, liquid outlet 5 and catalyst feeding port 6; a UV lamp 7 with a casing is placed in the center of the cylindrical cylinder, and a gas distributor 8 connected to the gas inlet 2 is provided under the UV lamp 7. The cylindrical cylinder There is a Helmholtz coil 9 arranged along its center outside the body; the ultraviolet lamp 7 and the Helmholtz coil 9 are connected to the power controller 10; the gas inlet 2 is connected with a flow buffer 11, a fan 12, and a liquid inlet 3 is connected to the pump 13 and the first liquid storage tank 14 through pipelines, and the liquid outlet 5 is connected to the second liquid storage tank 15 through pipelines.

[0018] The method for ...

Embodiment 2

[0021] A magnetically stable fluidized bed photocatalytic reactor, the structure of which is shown in Example 1.

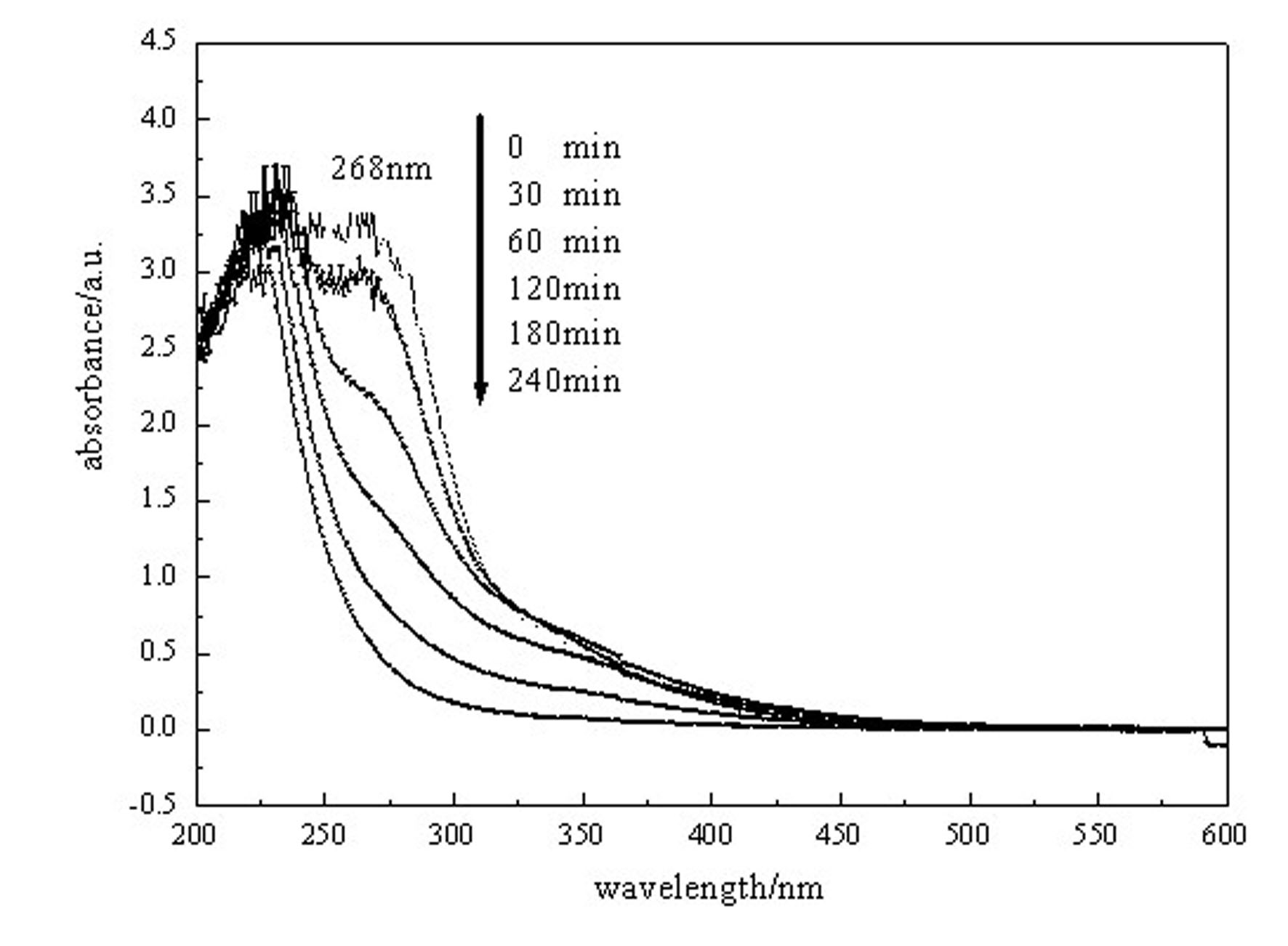

[0022] The method for treating refractory organic wastewater using the magnetically stable fluidized bed photocatalytic reactor comprises the following steps: 3 The organic wastewater nitrobenzene solution is placed in the first liquid storage tank, and is pumped to the liquid inlet of the magnetically stable fluidized bed photocatalytic reactor, and the magnetically loaded photocatalyst TiO 2 / SiO 2 / a-Fe 2 o 3 or TiO 2 / NiFe 2 o 4 Add the catalyst into the reactor from the catalyst feeding port, the dosage is 2.0 g / L, after the fan is turned on and passes through the flow buffer, the oxygen enters the gas distributor at the bottom of the magnetically stable fluidized bed photocatalytic reactor from the gas inlet, so that the magnetic The photocatalyst is in a suspension state, and then the gas is emptied from the gas outlet; the power controller of the Hel...

Embodiment 3

[0024] A magnetically stable fluidized bed photocatalytic reactor, the structure of which is shown in Example 1.

[0025] The method of using the magnetic stabilization fluidized bed light catalytic reactor to deal with difficulty degradation organic wastewater, including the following steps: the concentration is 200mg / m 3 The p-hydroxybenzoic acid solution of organic wastewater is placed in the first liquid storage tank, and is pumped to the liquid inlet of the magnetically stable fluidized bed photocatalytic reactor, and the magnetically loaded photocatalyst TiO 2 / SiO 2 / NiFe 2 o 4 or TiO 2 / CoFe 2 o 4 The catalyst is fed into the reactor through the catalyst feeding port, and the dosage is 0.1 g / L. After the fan is turned on and passes through the flow buffer, the air and ozone are mixed in any proportion and then enter the gas inlet at the bottom of the magnetically stable fluidized bed photocatalytic reactor. In the gas distributor, the magnetically loaded photocat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com