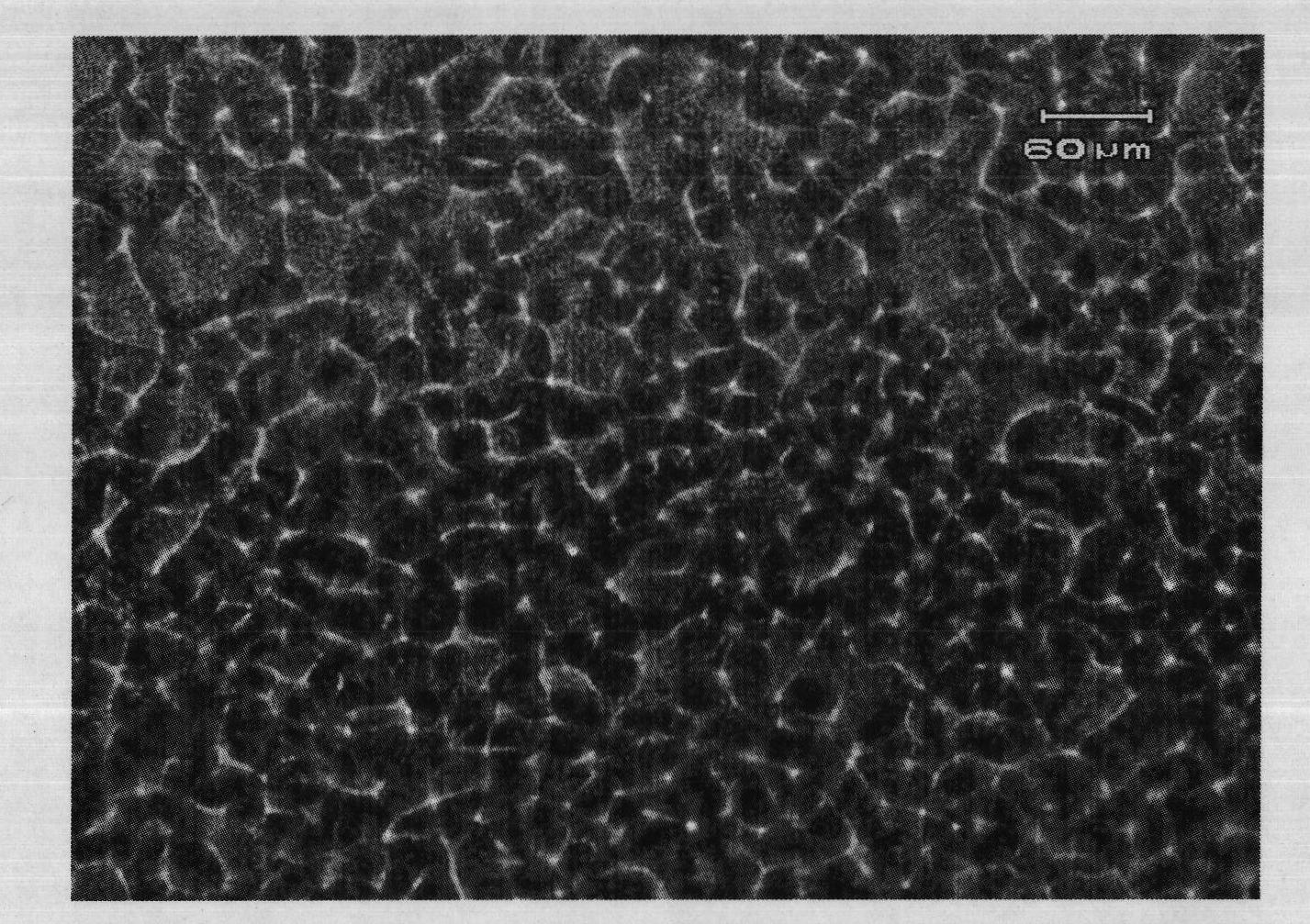

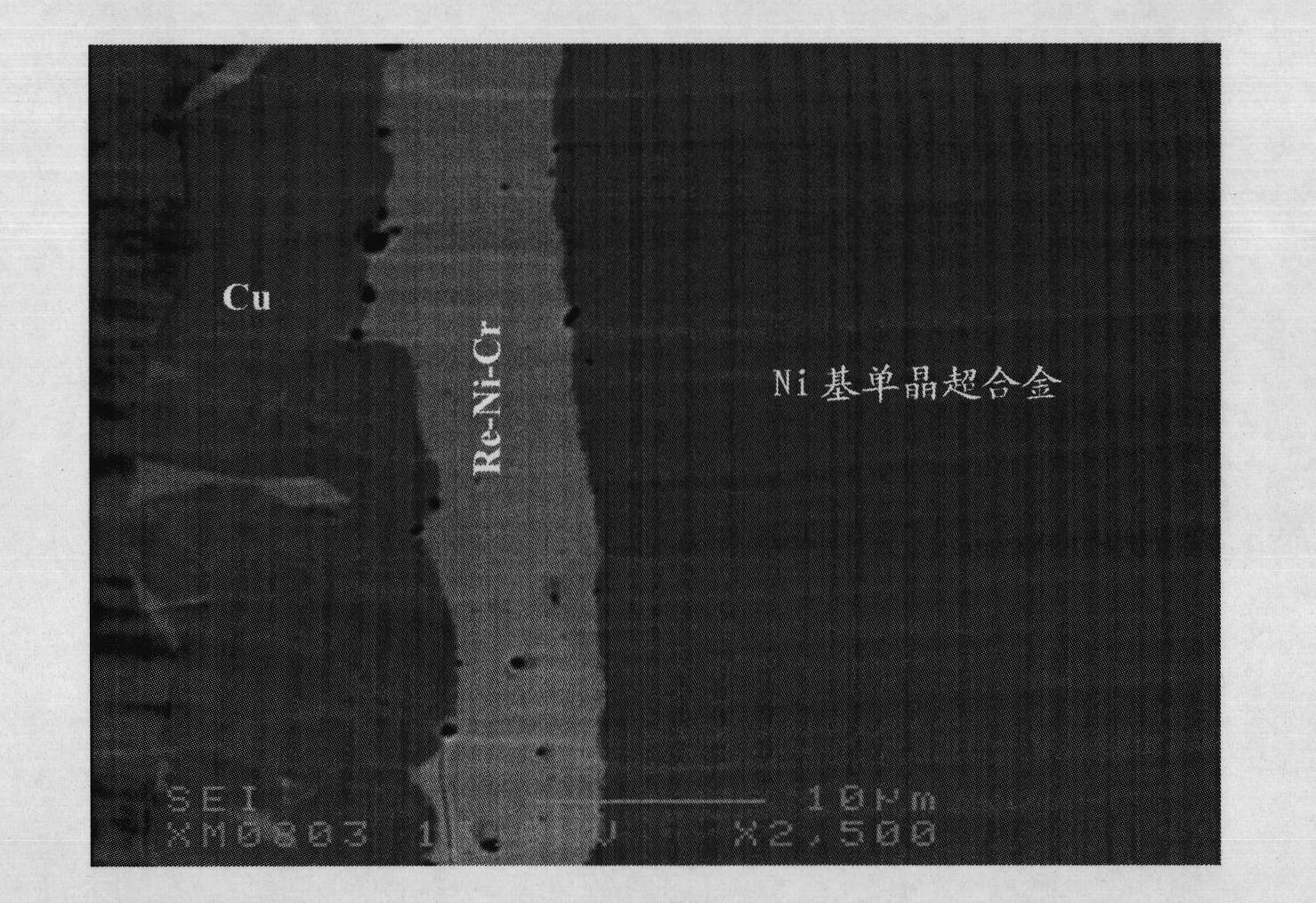

Bonding layer material having Re-Ni-Cr alloy diffusion barrier layer and preparation method thereof

A re-ni-cr, barrier layer technology, applied in solid diffusion coating, metal material coating process, coating and other directions, can solve problems such as reducing the life of thermal barrier coating, and achieve good application potential and good stability , the effect of reducing the interdiffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

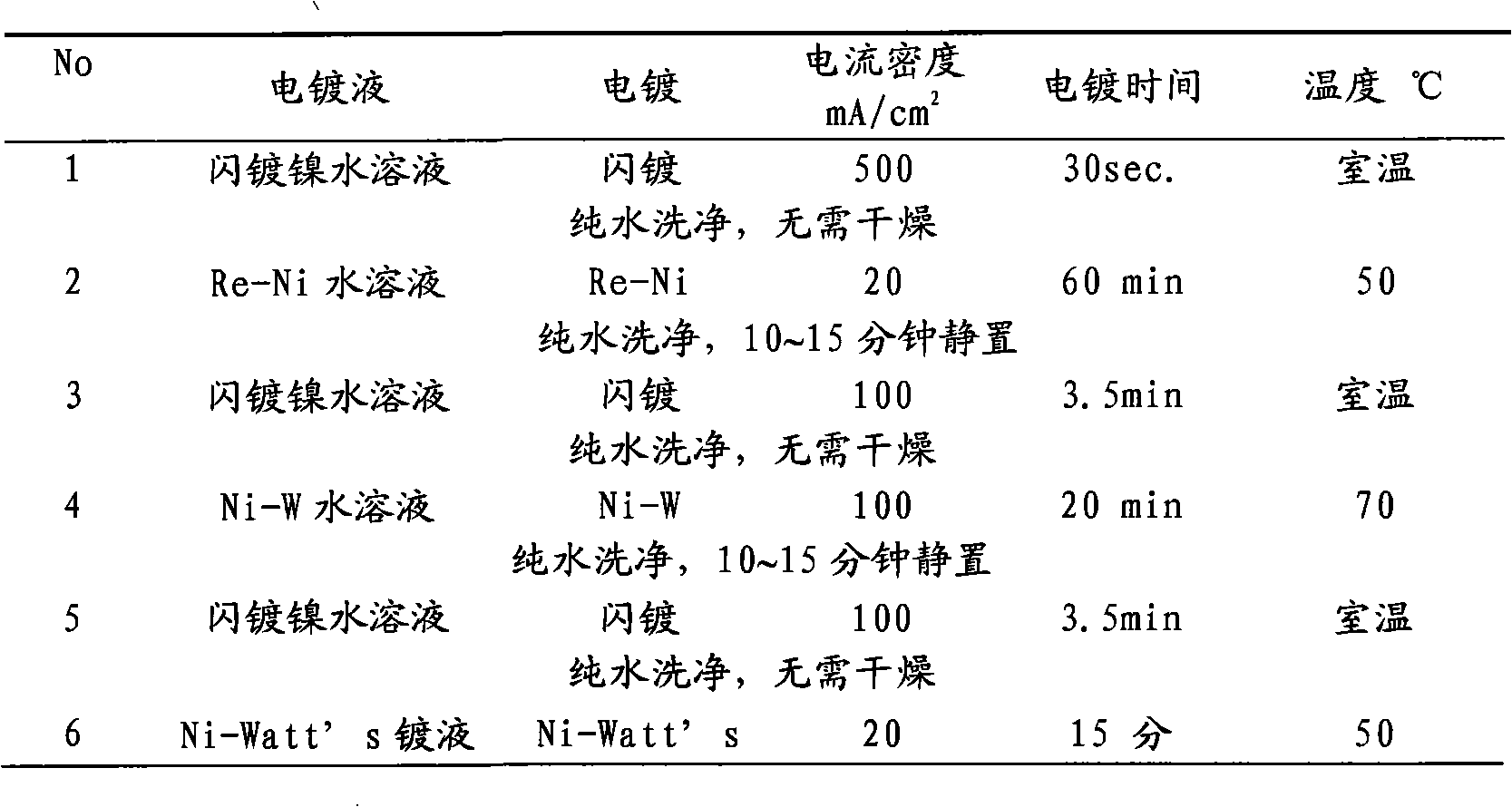

Embodiment 1

[0072] (1) Sample preparation

[0073] (1), cut the sample into blocks according to the thickness of 3mm;

[0074] (2) A 1.2mm hole is drilled on the upper end of the sample to facilitate the connection of the sample with Ni wire for electroplating;

[0075] (3) Grind the surface with #150 sandpaper, especially the corners should be ground slowly;

[0076] (4) Calculate the total area and weight of the sample.

[0077] The sample described therein is a Ni-based single crystal superalloy.

[0078] (2) Preparation of electrolyte

[0079] (1), preparation of flash nickel aqueous solution

[0080] ①. Wash the 1-liter beaker and prepare it for use;

[0081] ②. Add 600cc of pure water to the beaker, stir it magnetically, and prepare it for use;

[0082] ③. Add 205g nickel chloride and 125ml hydrochloric acid;

[0083] ④. When the volume of the solution is less than 1 liter, increase the volume of the solution to 1 liter;

[0084] ⑤. After 1.5 hours of magnetic stirring at room...

Embodiment 2

[0122] (1) Sample preparation

[0123] (1), cut the sample into blocks according to the thickness of 2mm;

[0124] (2) A hole of 1 mm is drilled on the upper end of the sample to facilitate the connection of the sample with Ni wire for electroplating;

[0125] (3) Grind the surface with #150 sandpaper, especially the corners should be ground slowly;

[0126] (4), calculate the total area and weight of the sample;

[0127] Wherein said sample is a Ni-based single crystal superalloy;

[0128] (2) Preparation of electrolyte

[0129] (1) Preparation of flash nickel aqueous solution

[0130] ①. Wash the 1-liter beaker and prepare it for use;

[0131] ②. Add 600cc of pure water to the beaker, stir it magnetically, and prepare it for use;

[0132] ③. Add 190.17g nickel chloride and 100ml hydrochloric acid;

[0133] ④. When the volume of the solution is less than 1 liter, increase the volume of the solution to 1 liter;

[0134] ⑤. After 1 hour of magnetic stirring at room temp...

Embodiment 3

[0171] (1) Sample preparation

[0172] (1), cut the sample into blocks according to the thickness of 5mm;

[0173] (2) A 1.5mm hole is drilled on the upper end of the sample to facilitate the connection of the sample with Ni wire for electroplating;

[0174] (3) Grind the surface with #150 sandpaper, especially the corners should be ground slowly;

[0175] (4), calculate the total area and weight of the sample;

[0176] Wherein said sample is a Ni-based single crystal superalloy;

[0177] (2) Preparation of electrolyte

[0178] (1) Preparation of flash nickel aqueous solution

[0179] ①. Wash the 1-liter beaker and prepare it for use;

[0180] ②. Add 600cc of pure water to the beaker, stir it magnetically, and prepare it for use;

[0181] ③. Add 285.25g nickel chloride and 130ml hydrochloric acid;

[0182] ④. When the volume of the solution is less than 1 liter, increase the volume of the solution to 1 liter;

[0183] ⑤. After 2 hours of magnetic stirring at room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com