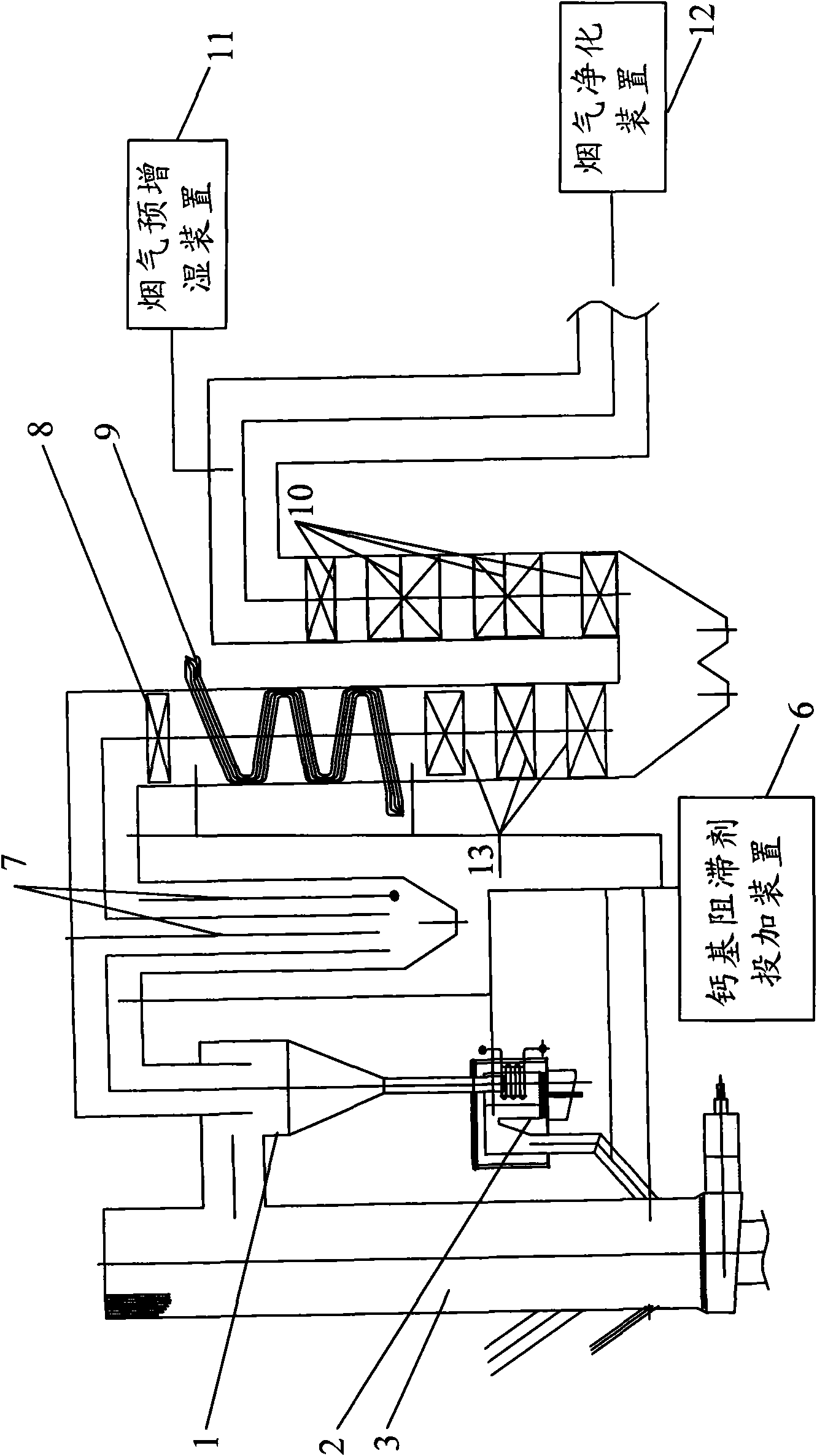

Refuse burning system and method with functions of deacidifying flue gas and retarding dioxin generation

A technology of waste incineration and waste incinerator, which is applied in the field of waste incineration system which has both flue gas deacidification and blocking of dioxin generation, can solve the problems of catalyst poisoning, natural environment damage, personal health injury, etc., and achieve blocking The effect of dioxin generation, reducing the amount of deacidification agent and reducing dioxin emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

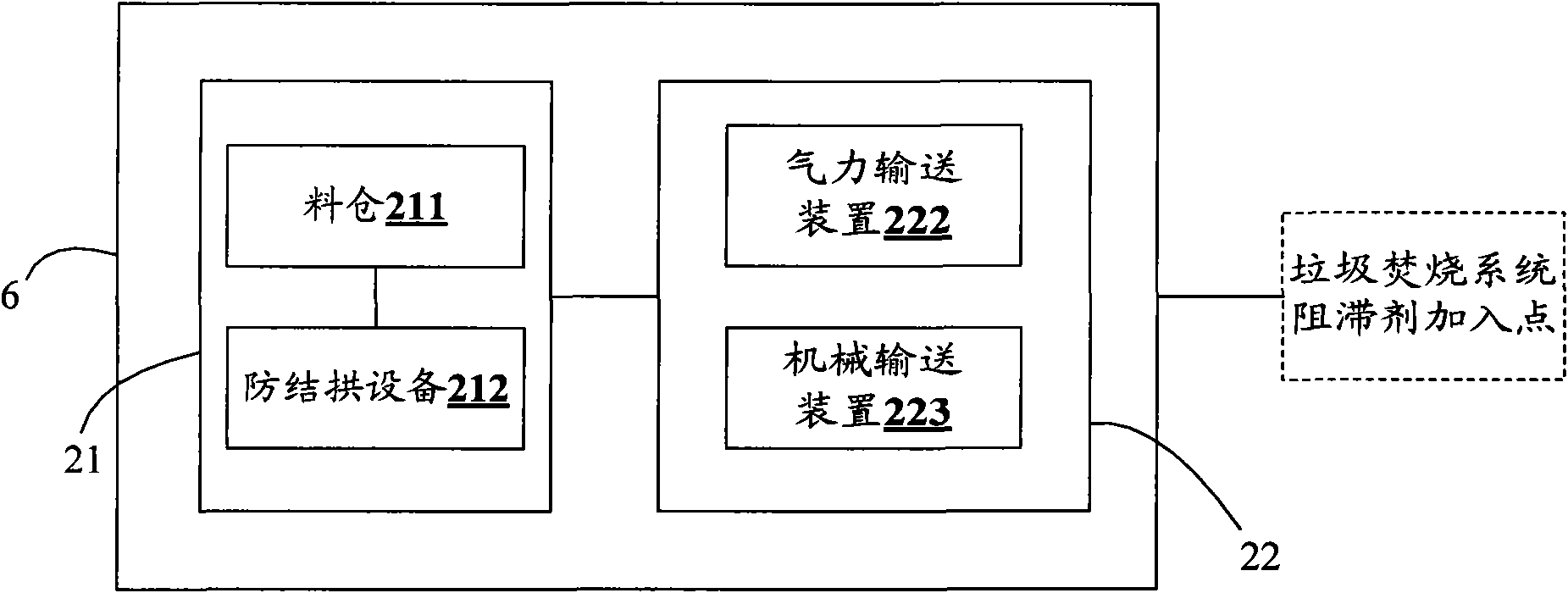

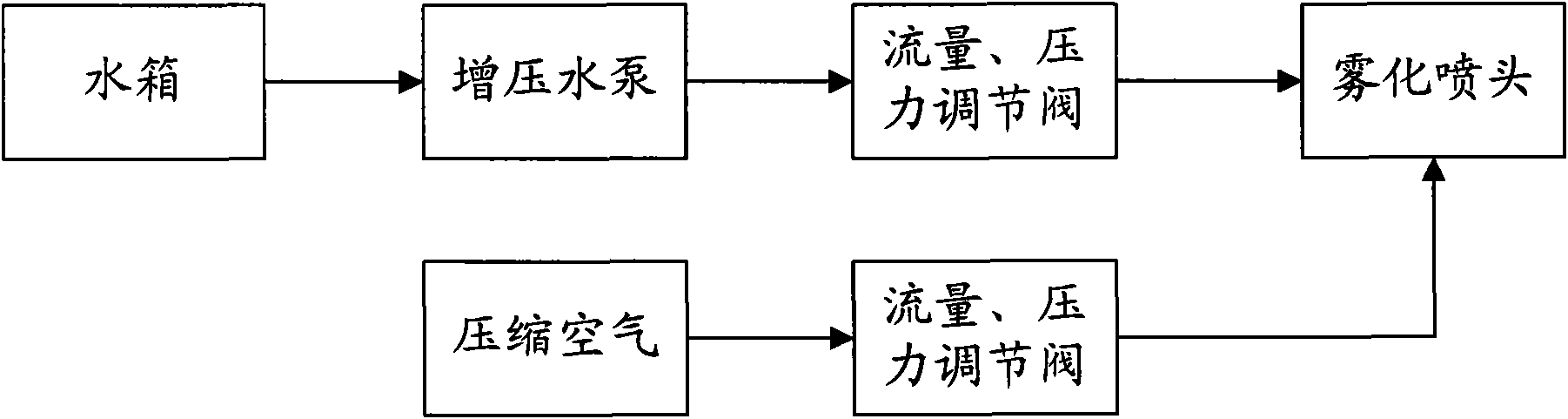

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] The mechanism of dioxin emission from waste incineration:

[0027] There are two reasons for the presence of dioxin-like substances in waste incineration emissions: one is that the dioxin-like substances mixed in the waste are not completely oxidized and decomposed during the incineration process, and the other is that the dioxin-like substances produced during the waste incineration process Evils. According to current research at home and abroad, there are three main mechanisms for the formation of dioxins during waste incineration:

[0028] (1) High temperature gas phase generation.

[0029] After the garbage enters the incinerator and starts to burn after drying and preheating, some garbage (large pieces) may be in a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com