Miniature optical fiber current sensor probe and making method thereof

A fiber-optic current sensing and fiber-optic current technology, which is applied in cladding optical fiber, voltage/current isolation, optics, etc., can solve the problems of reducing system sensitivity, system accuracy is easily affected by ambient temperature, etc., and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

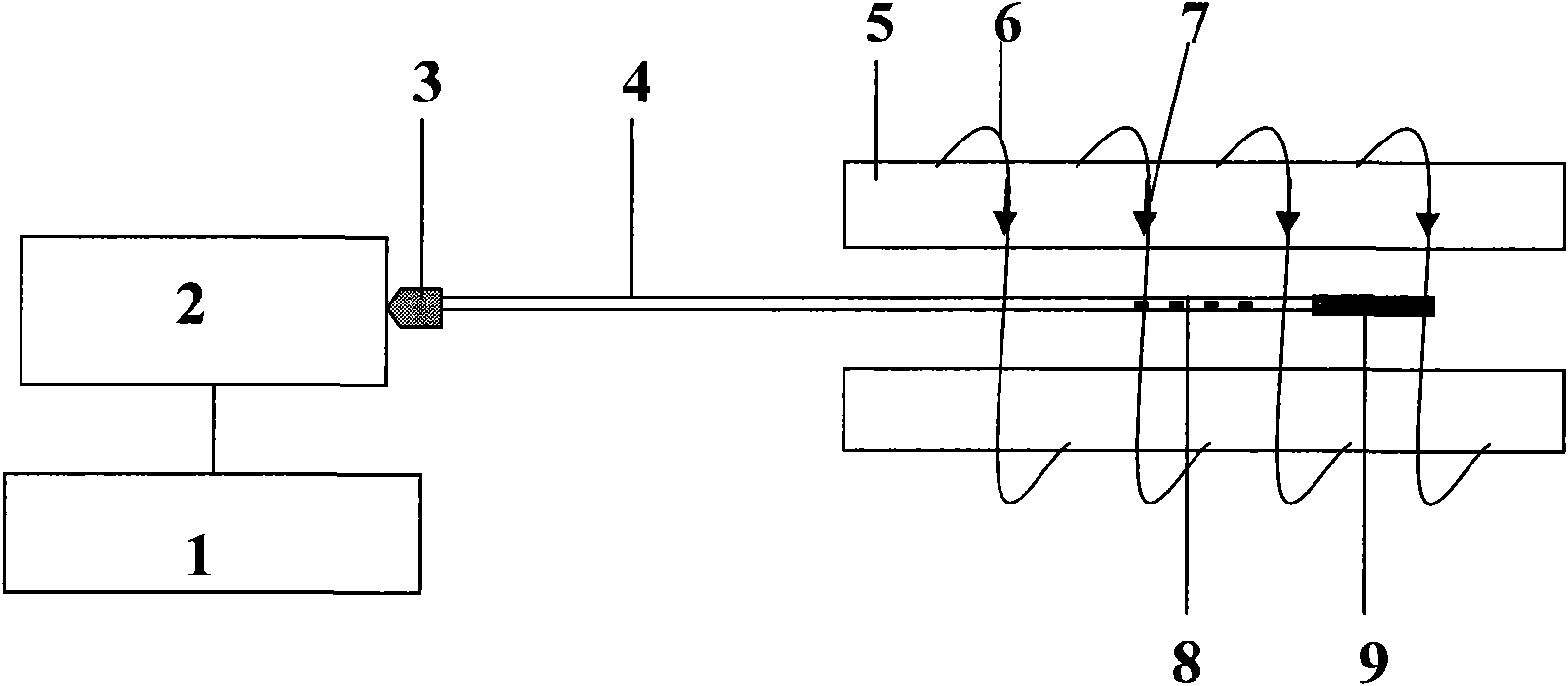

[0025] The implementation of the fiber optic current sensor in the invention will be described in further detail below in conjunction with the accompanying drawings

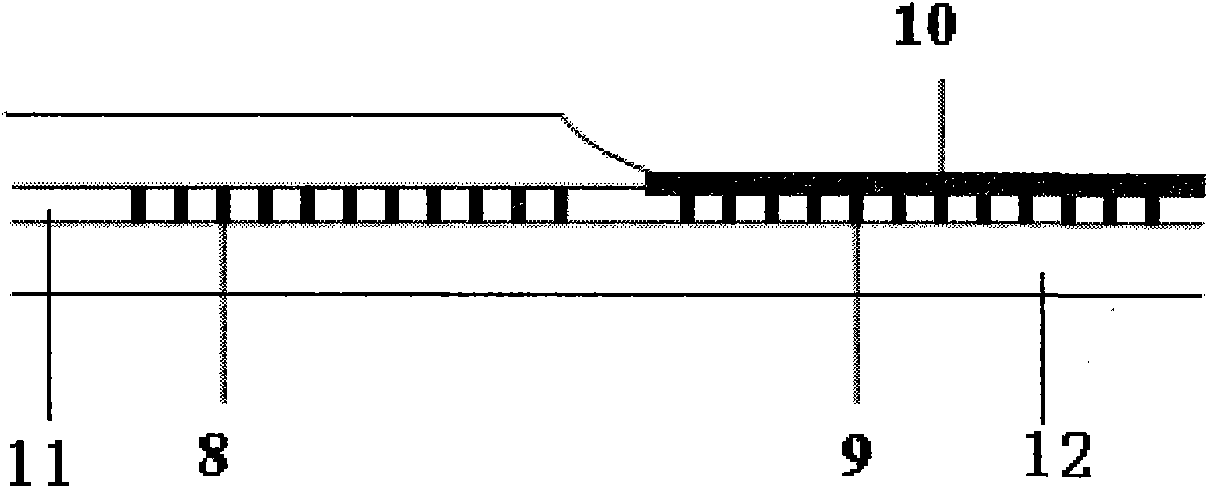

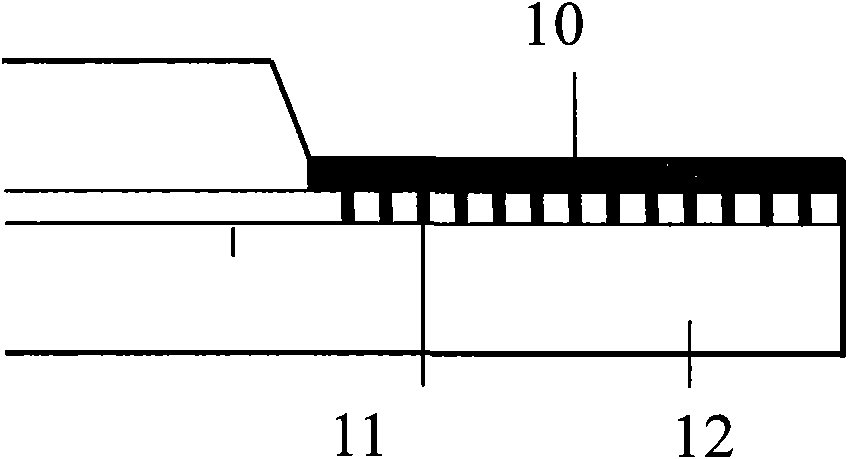

[0026] The micro fiber optic current sensor probe structure of the present invention is as figure 2 As shown, the probe is composed of a D-type fiber grating 9 sputtered with a TbDyFe thin film 10 and an uncoated reference grating 8 with the same central wavelength butt-welded.

[0027] Two fiber gratings with the same central wavelength are prepared in a single-mode fiber by phase mask method. One acts as a reference grating 8 for temperature compensation; the other acts as a D-type fiber grating 9 (sensing grating) and acts as a sensitive probe. In order to improve the sensitivity of the sensor probe, the fiber grating as a sensitive probe is fixed on a polishing machine for polishing, and a part of the fiber cladding 12 is removed, so that the fiber grating is polished close to the fiber core 11, so that a r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com