Driving system for light-emitting diode

A technology for light-emitting diodes and driving systems, applied in the field of light-emitting diode driving systems, can solve problems such as reducing system design flexibility and increasing system costs, and achieves the effects of saving external components, improving efficiency, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

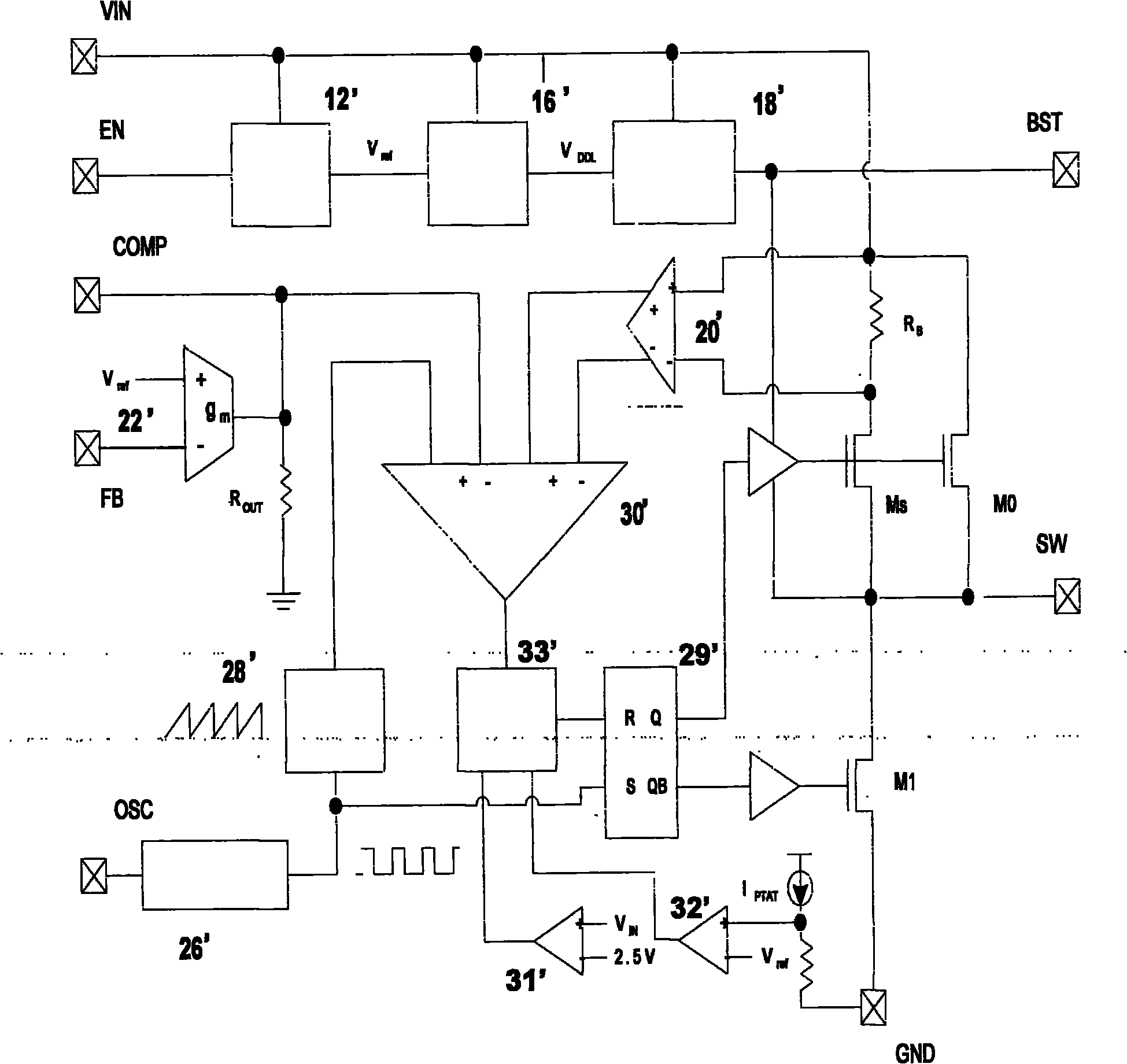

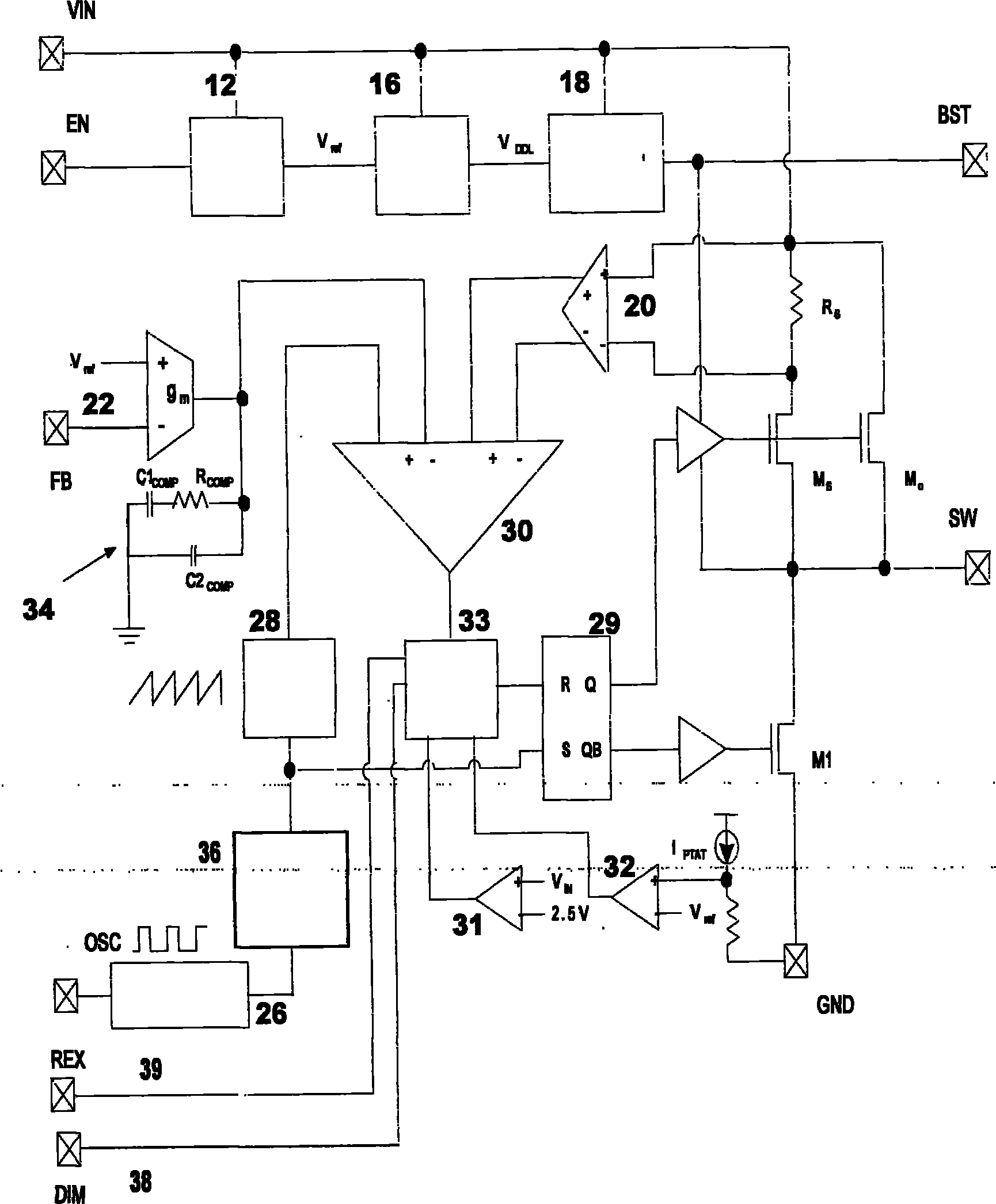

[0052] Such as figure 2 As shown, it is a circuit diagram of a light-emitting diode driving system, and the light-emitting diode driving system includes a circuit-connected reference bias module 12, a low-dropout voltage regulator 16, a bootstrap circuit 18, and a power switch tube M 0 and M S , inductor Rs, Schottky diode D1, current sense amplifier 20, PWM comparator 30, error amplifier 22, slope compensation circuit 28, logic circuit 33, RS latch 29, system oscillator 26, undervoltage lockout module 31 , and, thermal shutdown module 32;

[0053] The LED drive system sets the following pins: input voltage pin VIN, ground pin GND, feedback pin FB, pin SW connected to an external inductor, pin COMP connected to an external compensation circuit, and when grounded, the driver can be in The pin EN in the shutdown state and the bootstrap circuit pin BST;

[0054] The LED driver system also includes:

[0055] 1. An internal compensation module 34, the circuit of which is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com