Fe-Si-La alloy having excellent magneto-caloric properties

A 1.fe-si-la, fe1-b-b technology, applied in the field of Fe-Si-La alloys with excellent magnetocaloric properties, can solve the problems of difficult production of tantalum and hafnium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

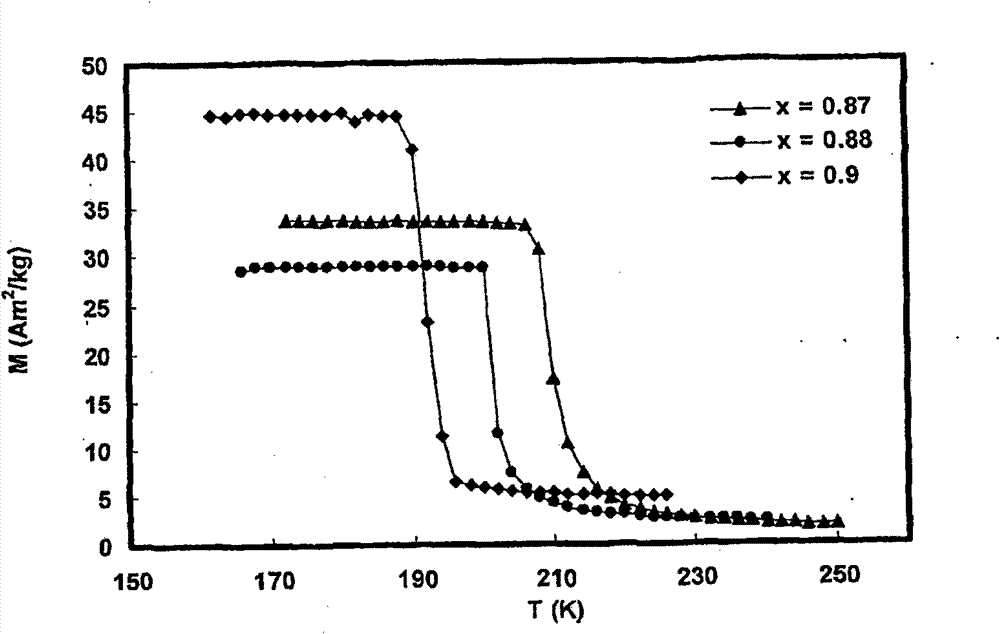

[0099] figure 1 show that, in materials containing no interstitial elements (C, N, H), the transition temperature T tr Never reached 220K. Therefore it is necessary to add these elements.

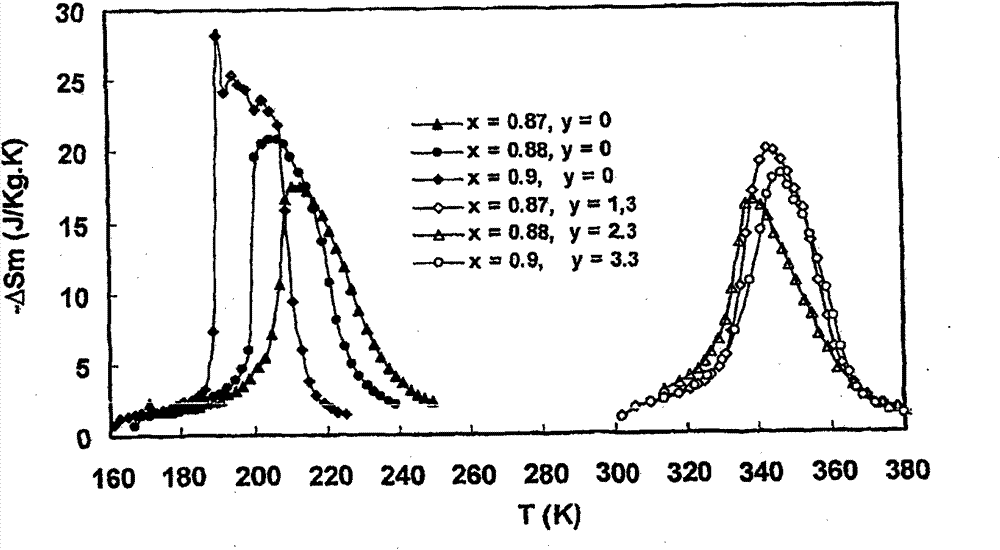

[0100] figure 2 shows that the high content of hydrogen intercalation makes the transition temperature T tr Significantly increased from 200K to 340K, while very moderately degrading the magnetocaloric properties.

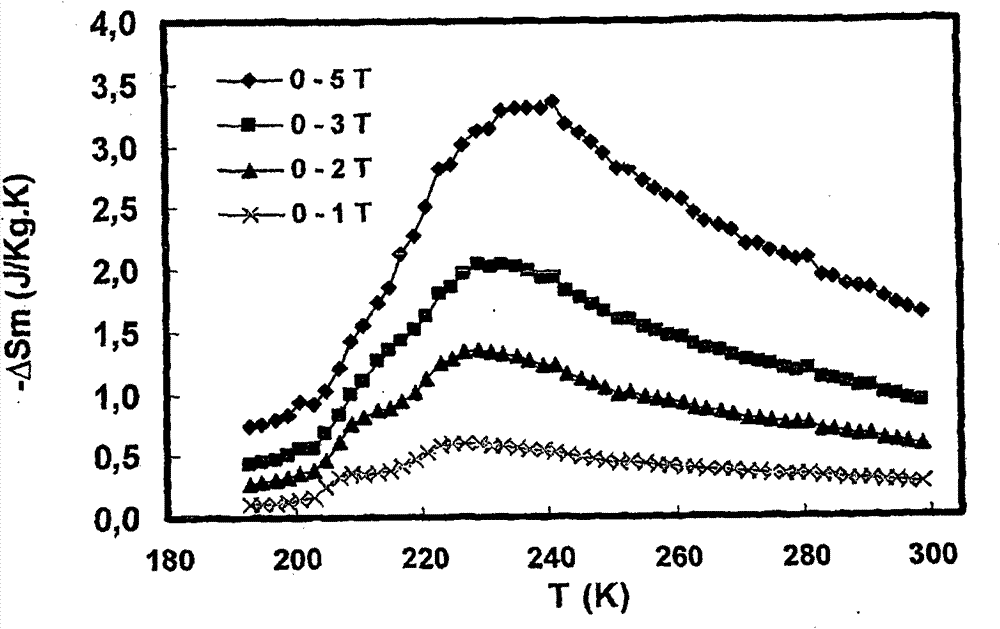

[0101] image 3 shows that the high content of nitrogen intercalation makes the transition temperature T tr Moderately increased from 200K to 230K, at the same time, significantly extended the MCE operating temperature range (ΔT at 2T LMH= 60K). Therefore, the magnetic transition temperature and the magnetocaloric effect temperature range can be advantageously shifted by intercalation of nitrogen and formation of nitrides. This serves to control the magnetic refrigeration over a wide temperature interval, eg 210-330K, by using more or less nitrided simple precursor all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com