Gelatin-chitosan-hyaluronic acid-heparan sulfate composite three-dimensional stent and preparation method thereof

A technology of hyaluronic acid and heparan sulfate, which is applied in the field of biomedicine to achieve the effect of uniform cell distribution and good proliferation and growth status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

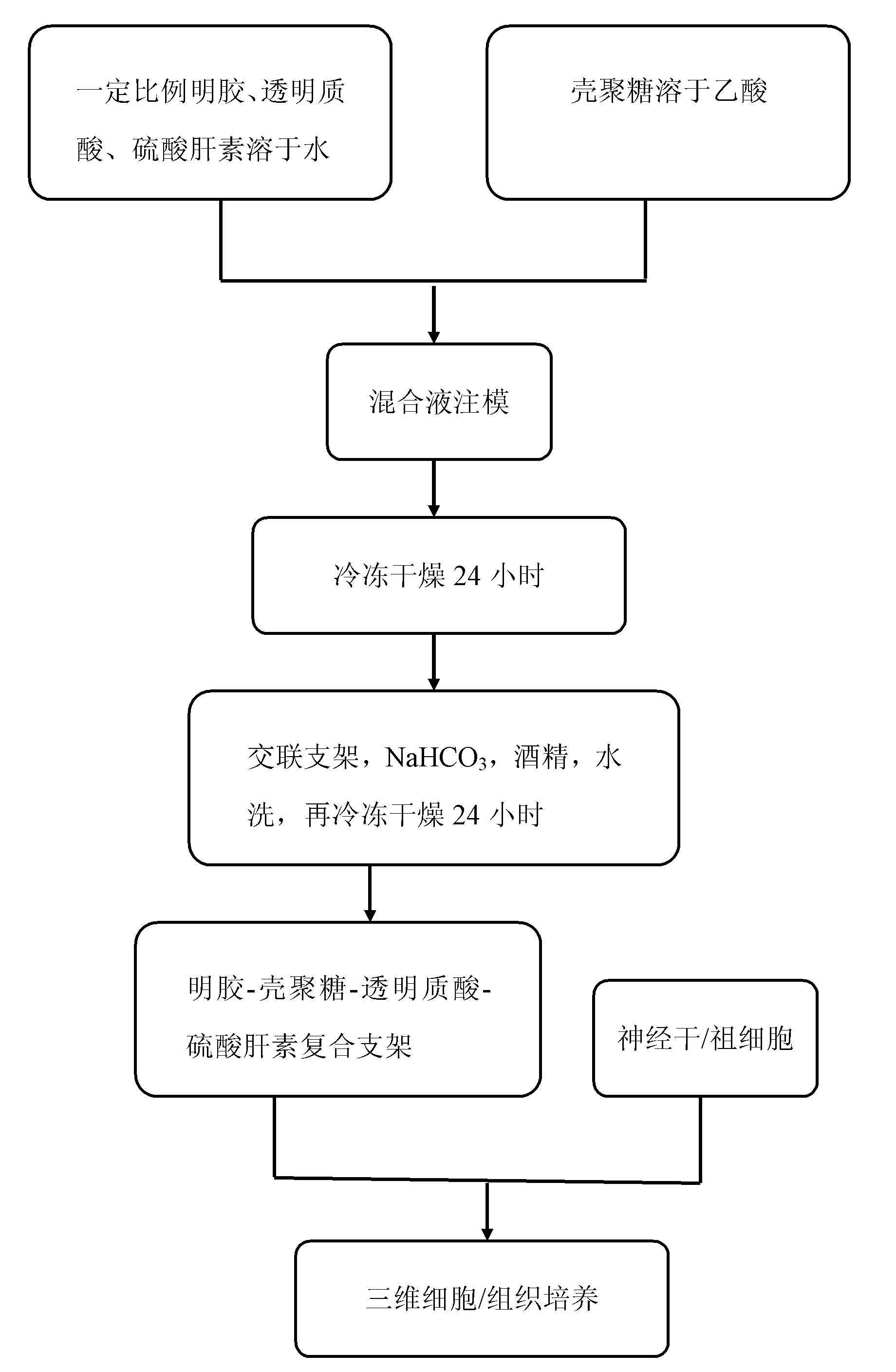

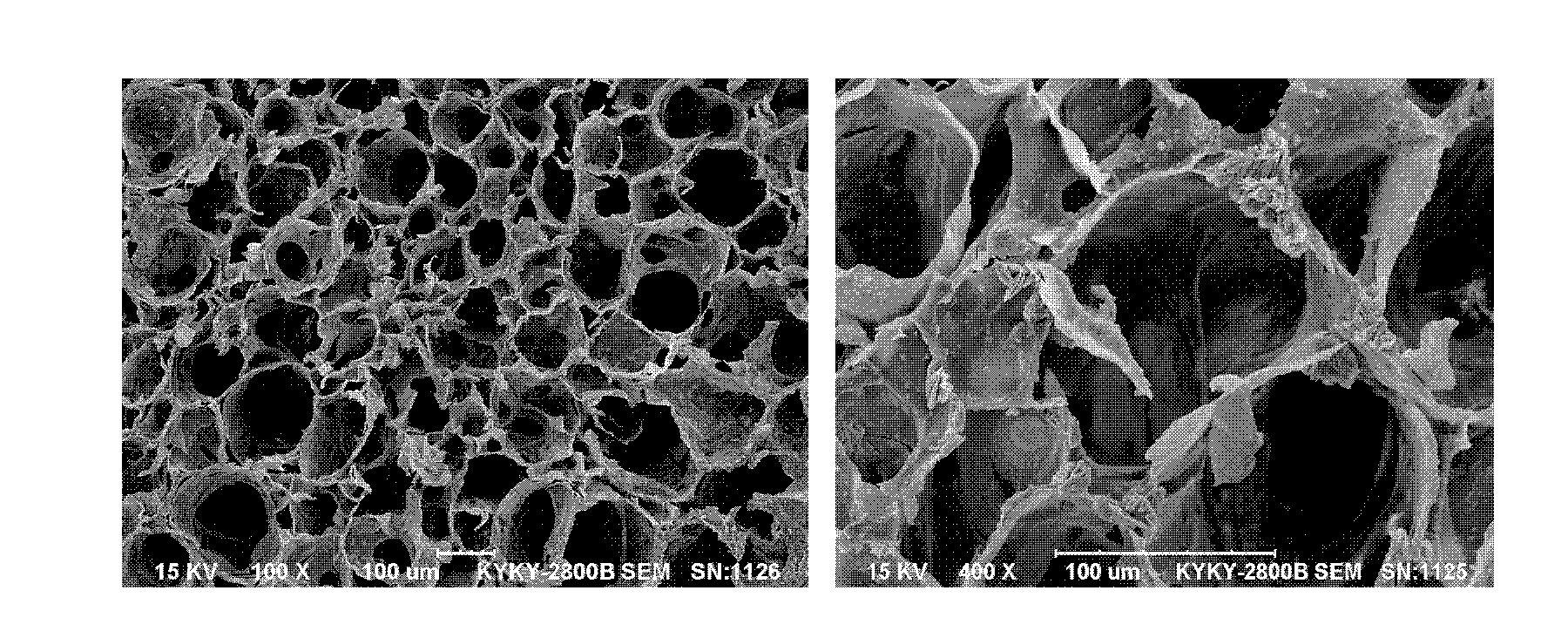

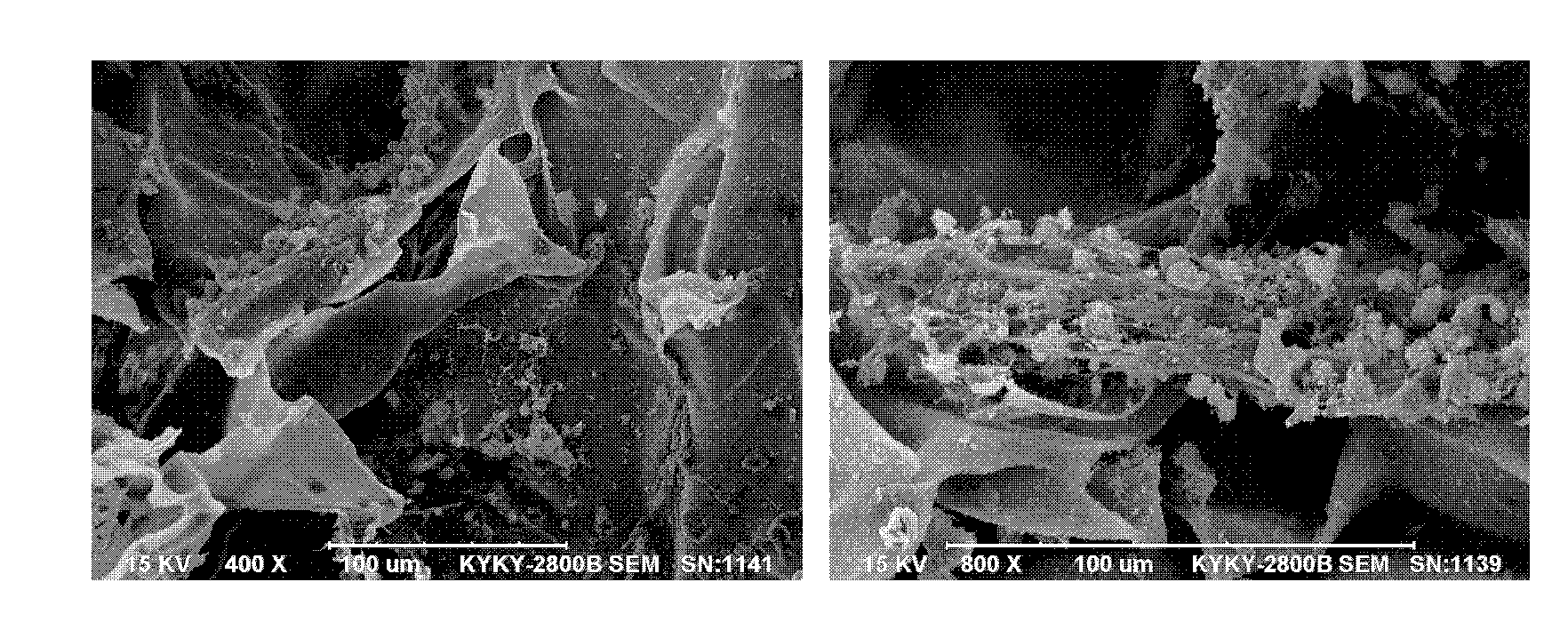

[0033] In a 60℃ water bath, dissolve gelatin, hyaluronic acid, and heparin sulfate in water to make 1.4% gelatin (W / V), 0.028% hyaluronic acid (W / V), and heparin sulfate 0.028% (W / V) mixed solution; dissolve chitosan powder in 2% (V / V) acetic acid to make 1.4% (W / V) chitosan solution, centrifuge, remove slag, and degas; The two solutions are quickly mixed evenly at a ratio of 5:5. The mixed solution was injected into a 96-well plate at 200 μL / well, pre-frozen at -80°C for 4 hours, and freeze-dried for 24 hours. After the stent is formed, the stent is cross-linked at room temperature with a cross-linking agent containing 50 mmol / L 2-morpholine ethanesulfonic acid, 50 mmol / L carbodiimide, and 50 mmol / L N-hydroxysuccinimide in 40% ethanol for 6 hours. Remove the cross-linking agent, and use pH 7.4, 0.1mol / L Na 2 HPO 4 Incubate the buffer for 2h at room temperature to neutralize residual acetic acid; wash 4 times with 40% (V / V) ethanol, 30min / time, rinse with double distilled wat...

example 2

[0035] In a 60℃ water bath, dissolve gelatin, hyaluronic acid and heparin sulfate in water to make 1.8% gelatin (W / V), 0.036% hyaluronic acid (W / V), and heparin sulfate 0.036% (W / V) mixed solution; dissolve the chitosan powder in 2% (V / V) acetic acid to make a 1.8% (W / V) chitosan solution, centrifuge, remove slag, and degas; The two solutions are quickly mixed evenly at a ratio of 5:5. The mixed solution was injected into a 96-well plate at 200 μL / well, pre-frozen at -80°C for 4 hours, and freeze-dried for 24 hours. After the stent is formed, the stent is cross-linked at room temperature with a cross-linking agent containing 50 mmol / L 2-morpholine ethanesulfonic acid, 50 mmol / L carbodiimide, and 50 mmol / L N-hydroxysuccinimide in 40% ethanol for 6 hours. Remove the cross-linking agent, and use pH 7.4, 0.1mol / L Na 2 HPO 4 Incubate the buffer for 2h at room temperature to neutralize residual acetic acid; wash 4 times with 40% (V / V) ethanol, 30min / time, rinse with double distille...

example 3

[0037] In a 60℃ water bath, dissolve gelatin, hyaluronic acid, and heparin sulfate in water to prepare 2% gelatin (W / V), 0.04% hyaluronic acid (W / V), and heparin sulfate 0.04% (W / V) mixed solution; dissolve the chitosan powder in 2% (V / V) acetic acid to make a 2% (W / V) chitosan solution, centrifuge, remove slag, and degas; The two solutions are quickly mixed evenly at a ratio of 5:5. The mixed solution was injected into a 96-well plate at 200 μL / well, pre-frozen at -80°C for 4 hours, and freeze-dried for 24 hours. After the stent is formed, the stent is cross-linked at room temperature with a cross-linking agent containing 50 mmol / L 2-morpholine ethanesulfonic acid, 50 mmol / L carbodiimide, and 50 mmol / L N-hydroxysuccinimide in 40% ethanol for 6 hours. Remove the cross-linking agent, and use pH 7.4, 0.1mol / L Na 2 HPO 4 Incubate the buffer for 2h at room temperature to neutralize residual acetic acid; wash 4 times with 40% (V / V) ethanol, 30min / time, rinse with double distilled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com