Screw extruder barrel and temperature control method thereof

A screw extruder and barrel technology, which is used in the field of barrel temperature control and the improvement of heating/cooling channel structure, can solve the problem of low temperature control sensitivity, excessive local temperature difference at the alternation, and limited temperature control range and temperature control accuracy. and other problems, to achieve the effect of improving control sensitivity, reducing energy loss, and reducing controlled volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

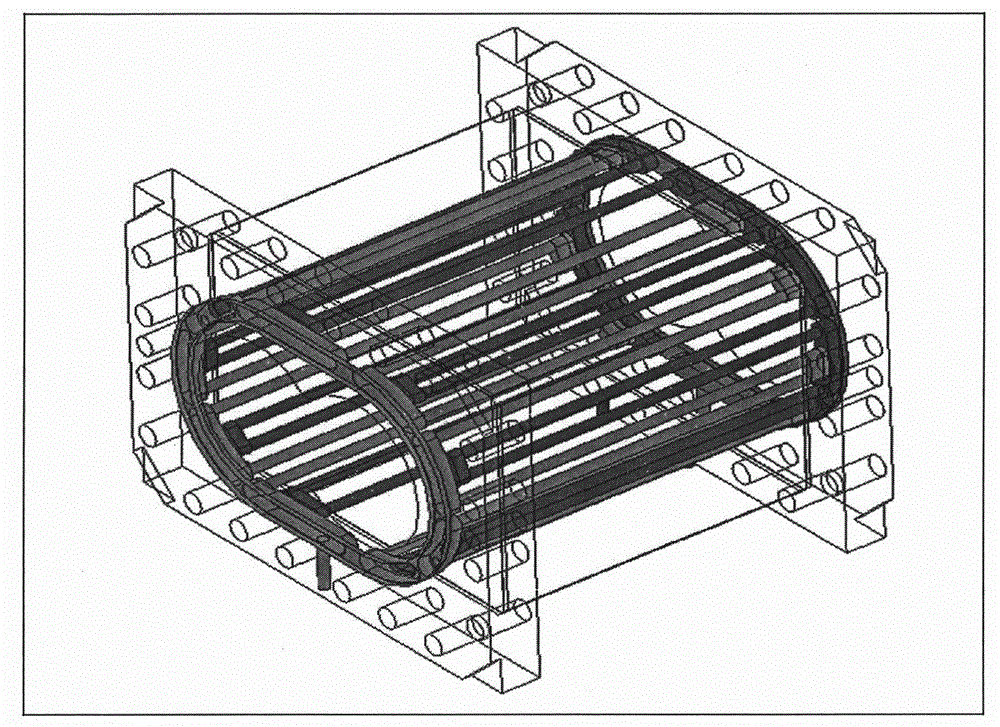

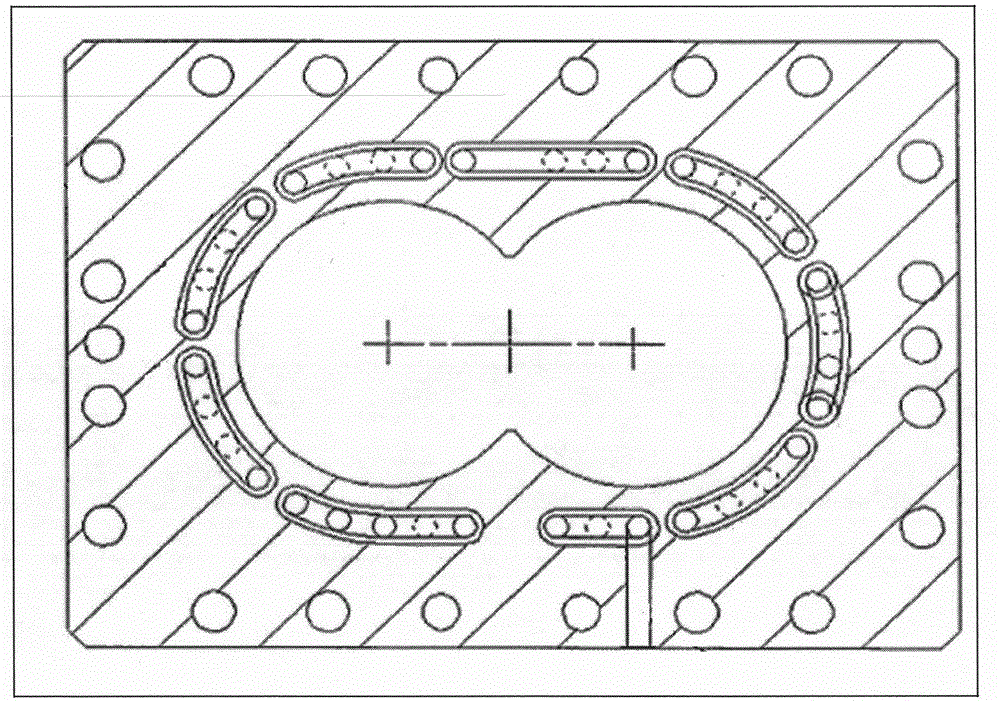

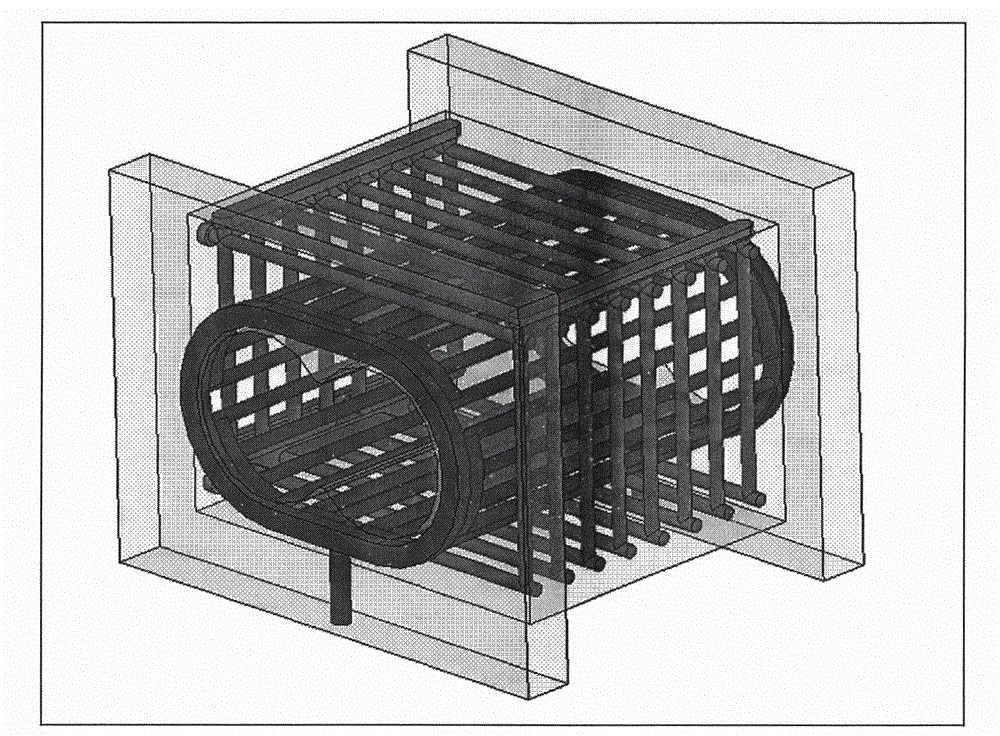

[0035] The structure of the double-layered dual-channel barrel of the present invention is as image 3 , Figure 4 , Figure 5 As shown, on two different radial levels of the barrel cross-section, there are multiple heat conduction medium flow channels in two layers. According to the actual processing conditions and control requirements, the heating medium or cooling medium can be passed into the flow channel, and the outside The laminar flow channels are opened along the circumference of the barrel, the inner flow channels are opened along the axis of the barrel, and the flow channels of each layer are connected in parallel. The expansion diagram of the inner runner is as follows Image 6 As shown, a two-way parallel structure is used. The heat transfer medium flows into the pipes 26 and 25 from the oil inlet, and then sequentially flows through 24 and 23, 22 and 21, 20 and 19, 18 and 17, 16 and 15, 14 and 13, 12 and 11, 10 and 9, 8 and 7, 6 and 5, 4 and 3, 2 and 1, and finall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com