Gas breaking and gas stripping linked double-phase vacuum underground water pumping in-situ repair method

A technology of vacuum suction and in-situ repair, which is applied in separation methods, chemical instruments and methods, and restoration of polluted soil, etc. Obvious and other problems, to achieve the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with accompanying drawings and examples.

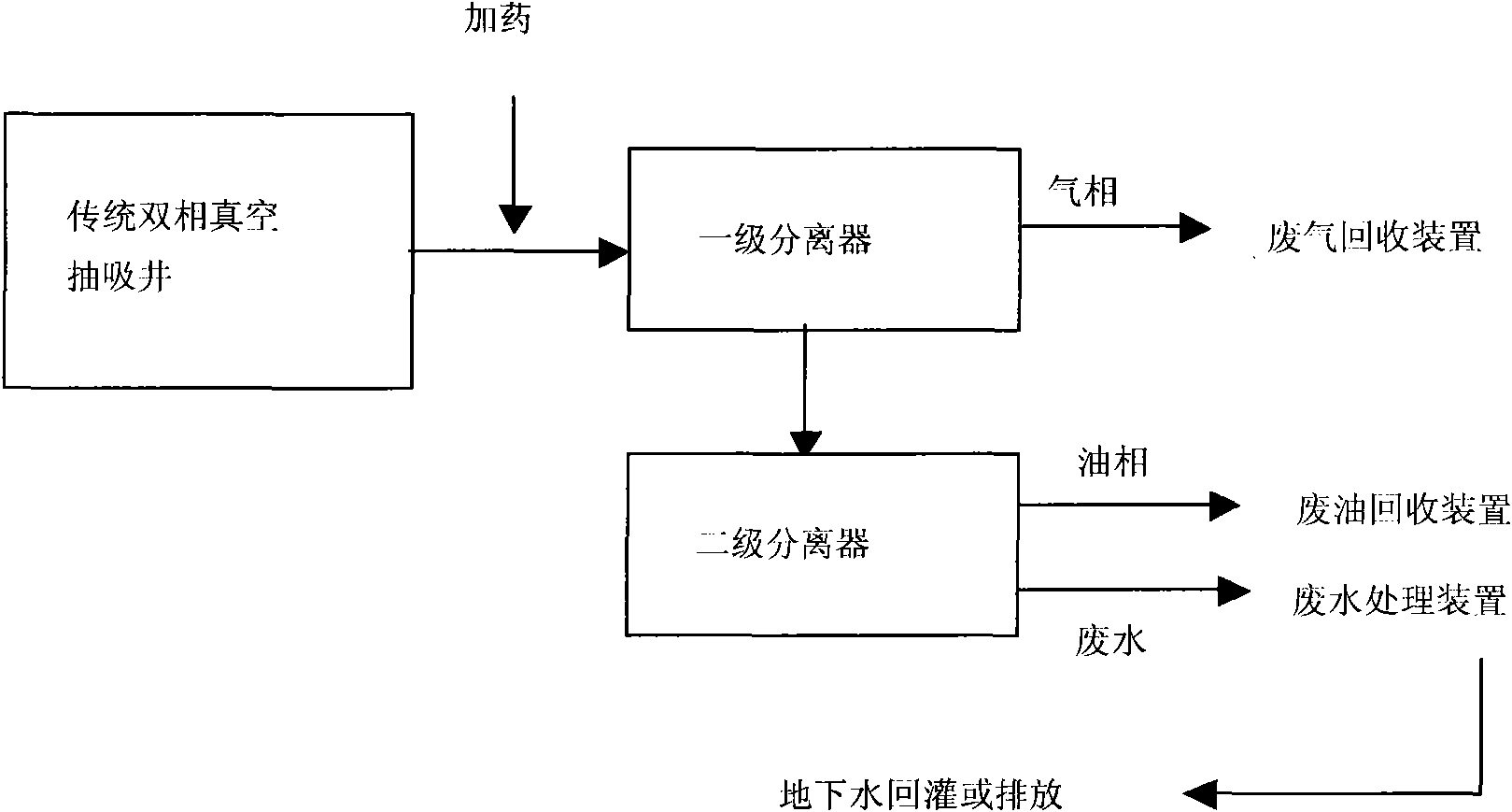

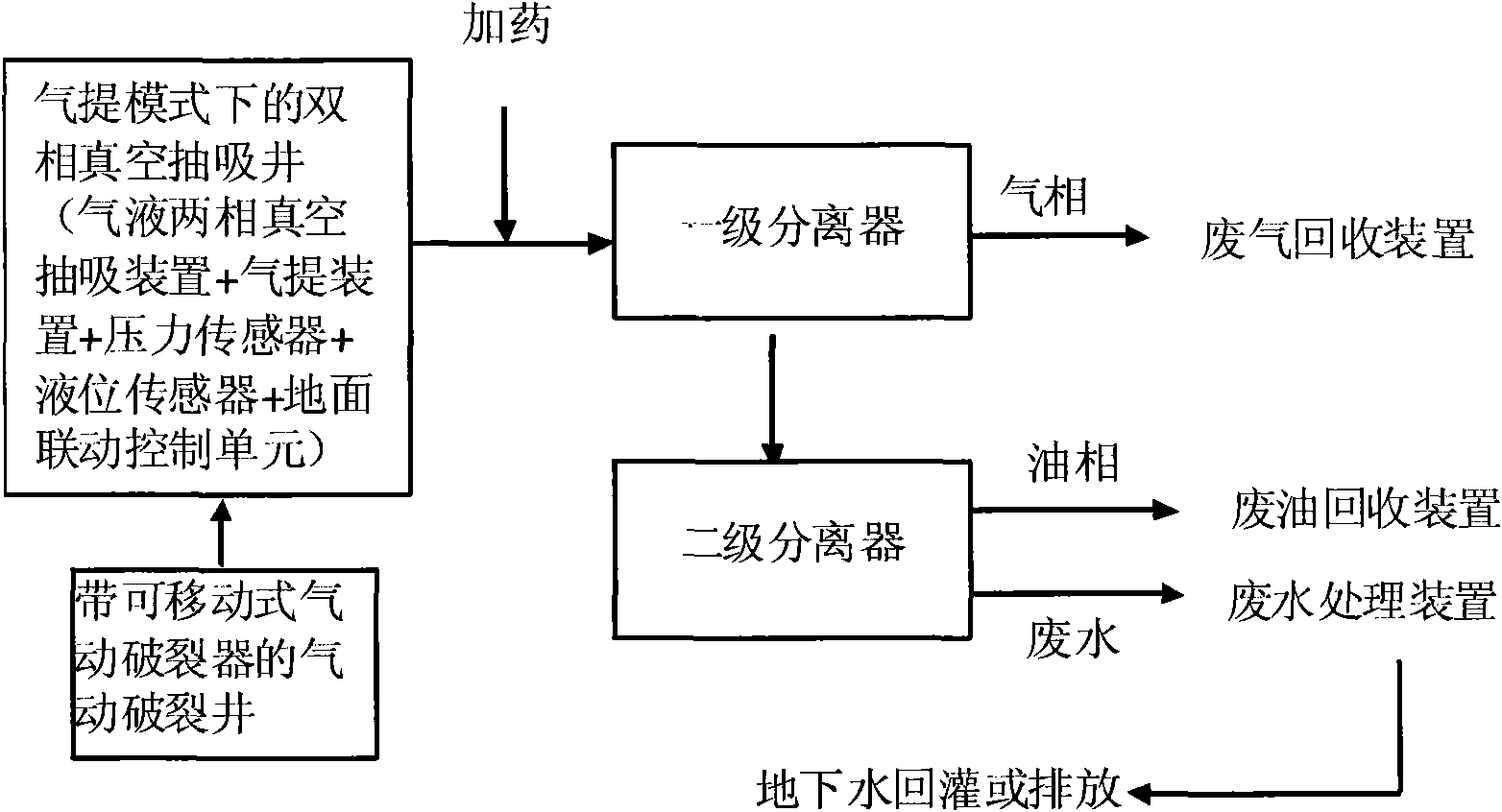

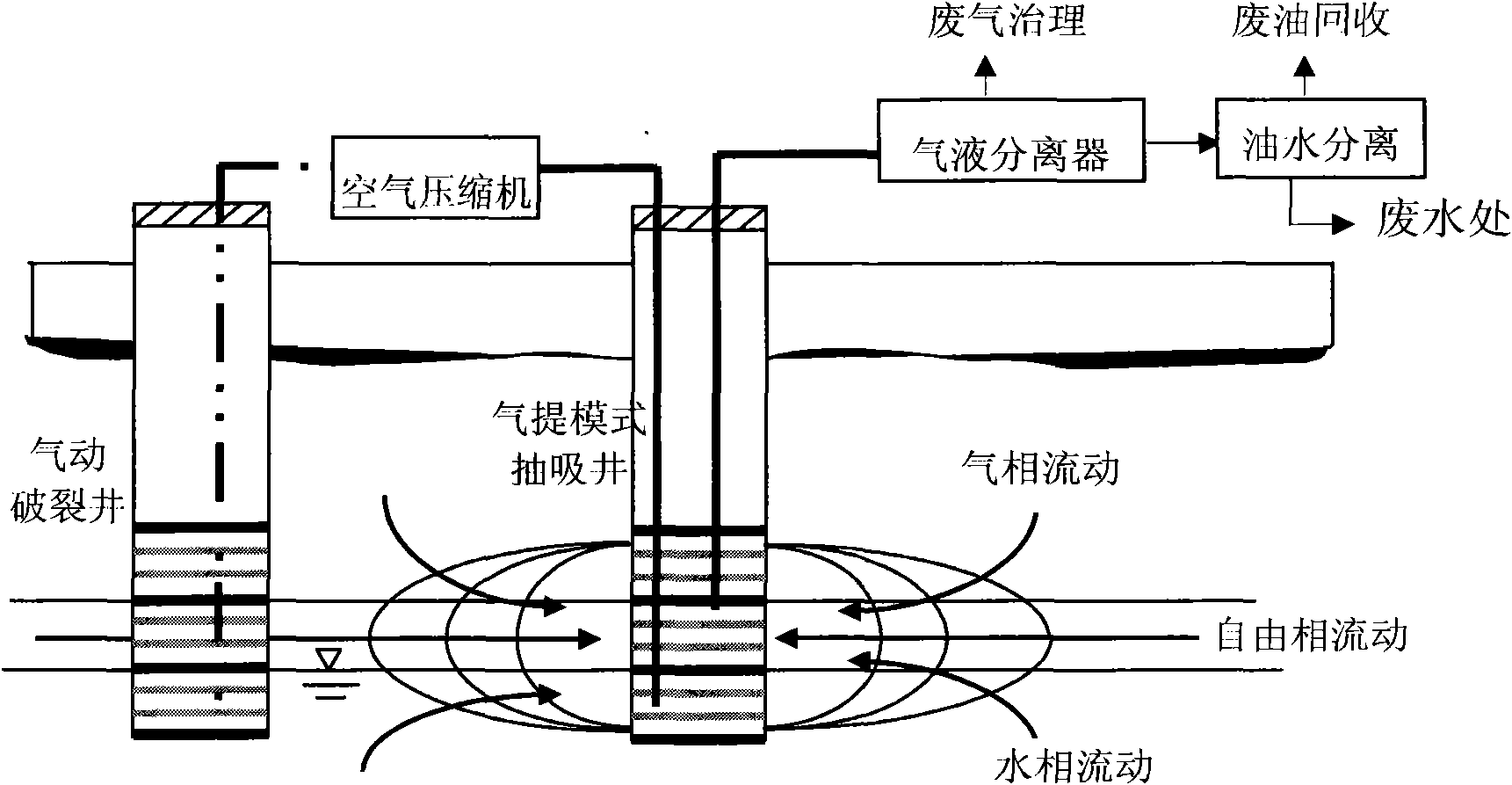

[0044] The present invention promotes the above-mentioned process and improves the extraction efficiency by respectively installing an air lift device in a two-phase vacuum suction well and setting a pneumatic fracturing well near the well. At the same time, the present invention provides a linkage scheme with air lift, vacuum suction and pneumatic fracturing, which can be automatically adjusted according to the changes in operating parameters in the wells equipped with suction and pneumatic fracturing to achieve an optimal combination of efficiency and cost . The monitoring and control of operating parameters are mainly realized by installing vacuum sensors, liquid level sensors and programming automatic control. The invented air breaking and air lifting coordinated two-phase vacuum suction method involves two-phase vacuum suction wells, pneumatic fracturi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com