Field effect transistor chiral sensor and manufacture method thereof

A field-effect transistor and sensor technology, applied in the field of sensors, can solve the problems of easy pollution and sensor application limitations, and achieve the effects of no reagent consumption, reduced environmental pollution, and easy deviceization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

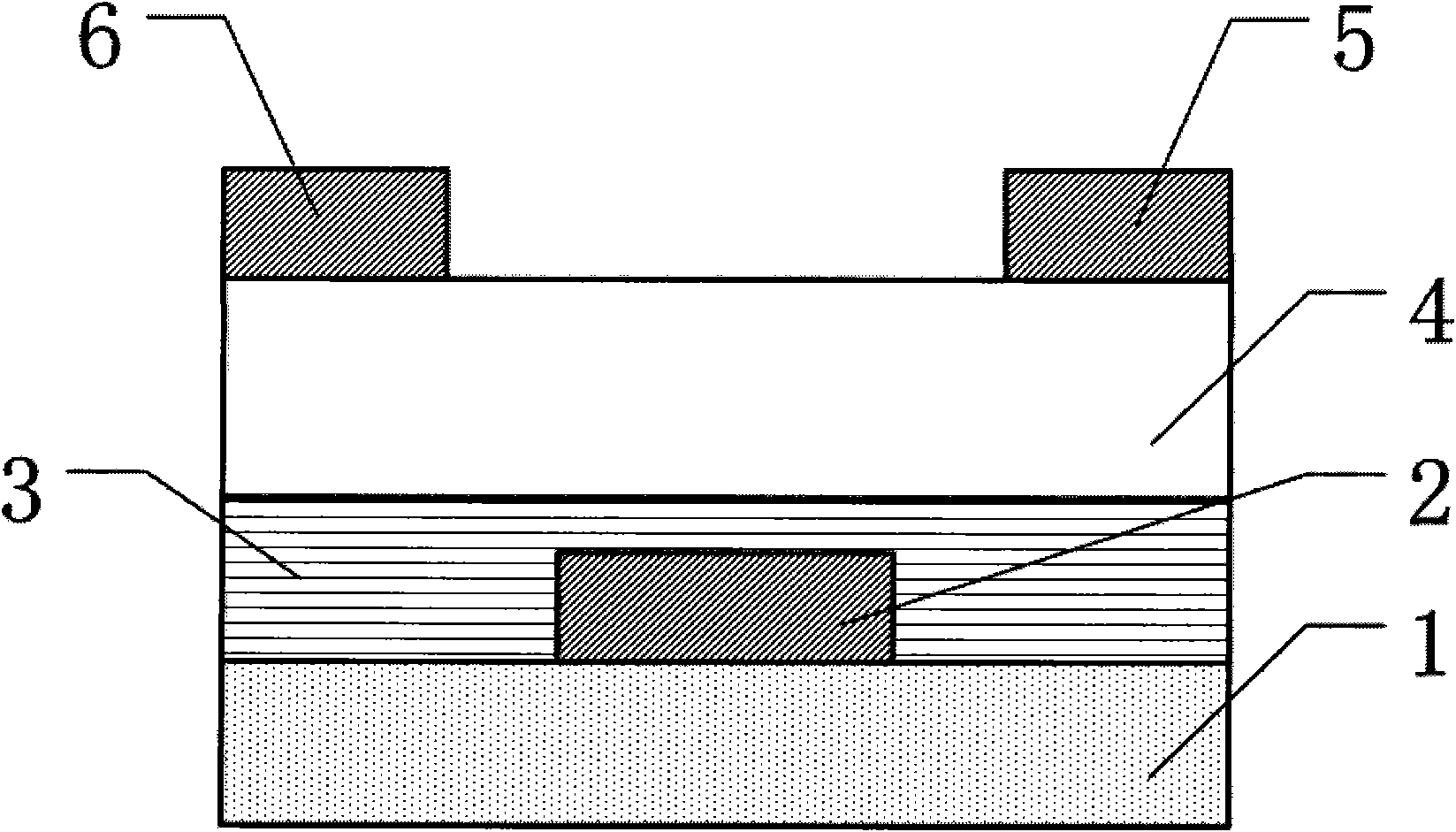

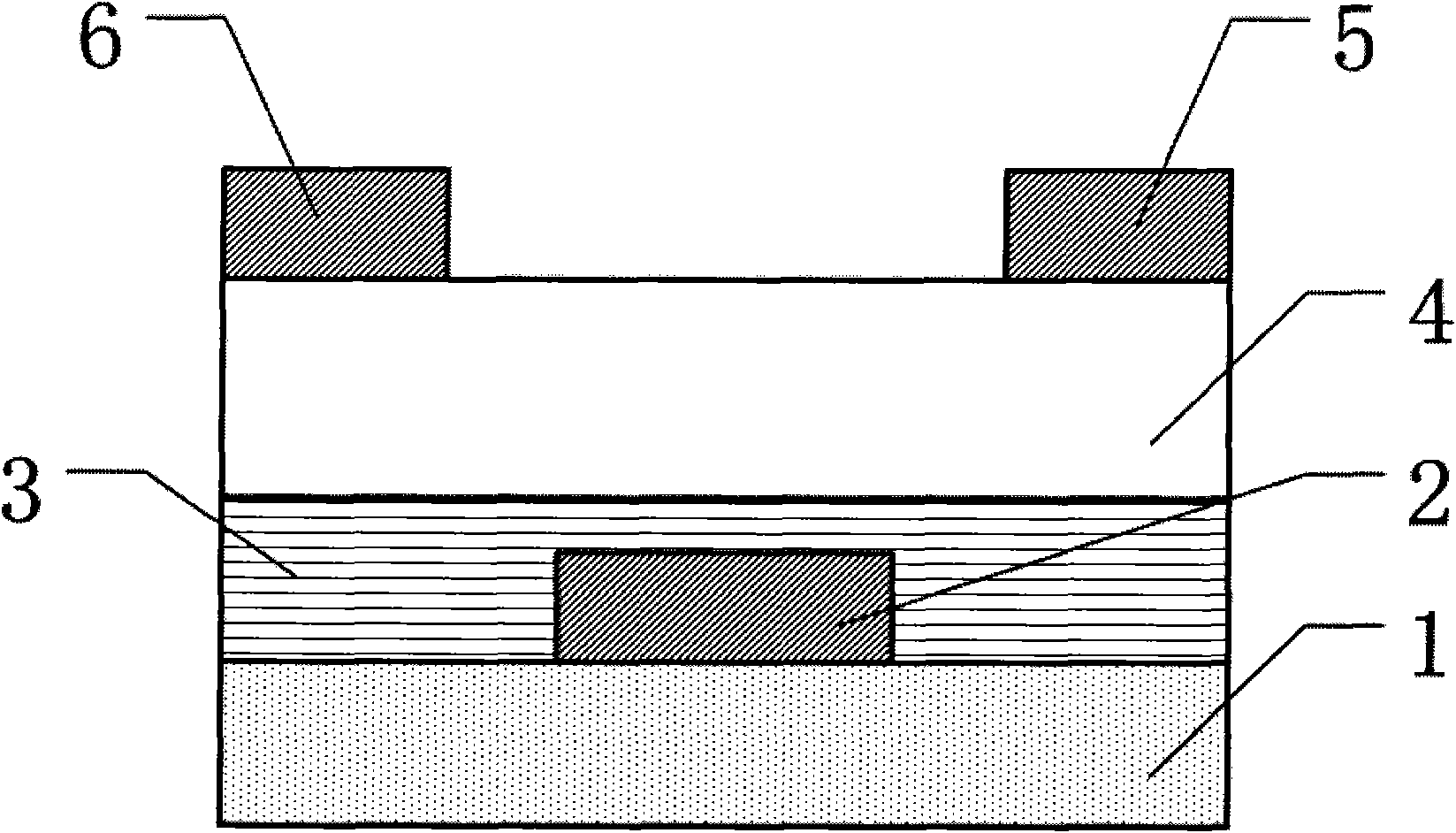

[0026] What is obtained by this preparation method is a top-contact quantum dot field effect transistor chiral sensor:

[0027] Step 1, sputtering or evaporating a layer of gate electrode 2 with a thickness of 10nm-500nm on the substrate 1, the gate electrode is composed of one or two of Ta, Ti, Cr, W, Mo, Au or Ag.

[0028] Step 2, sputtering or evaporating a layer of high dielectric constant gate insulating layer 3 with a thickness of 150nm to 500nm, the gate insulating layer is made of SiO 2 、 Ta 2 o 5 、Al 2 o 3 、TiO 2 , BZT, or PZT in one or two forms.

[0029] Step 3, by spin coating, inkjet printing or screen printing a layer of active layer 4 with a thickness of 10 nm to 500 nm, wherein the active layer 4 can be one or both of the following two different compounds modified by chiral molecules Combination. They are: (a) Group II-VI compounds; (b) Group III-V compounds.

[0030] Step 4, sputtering, inkjet printing or evaporating a layer of source electrode 5 and d...

Embodiment 2

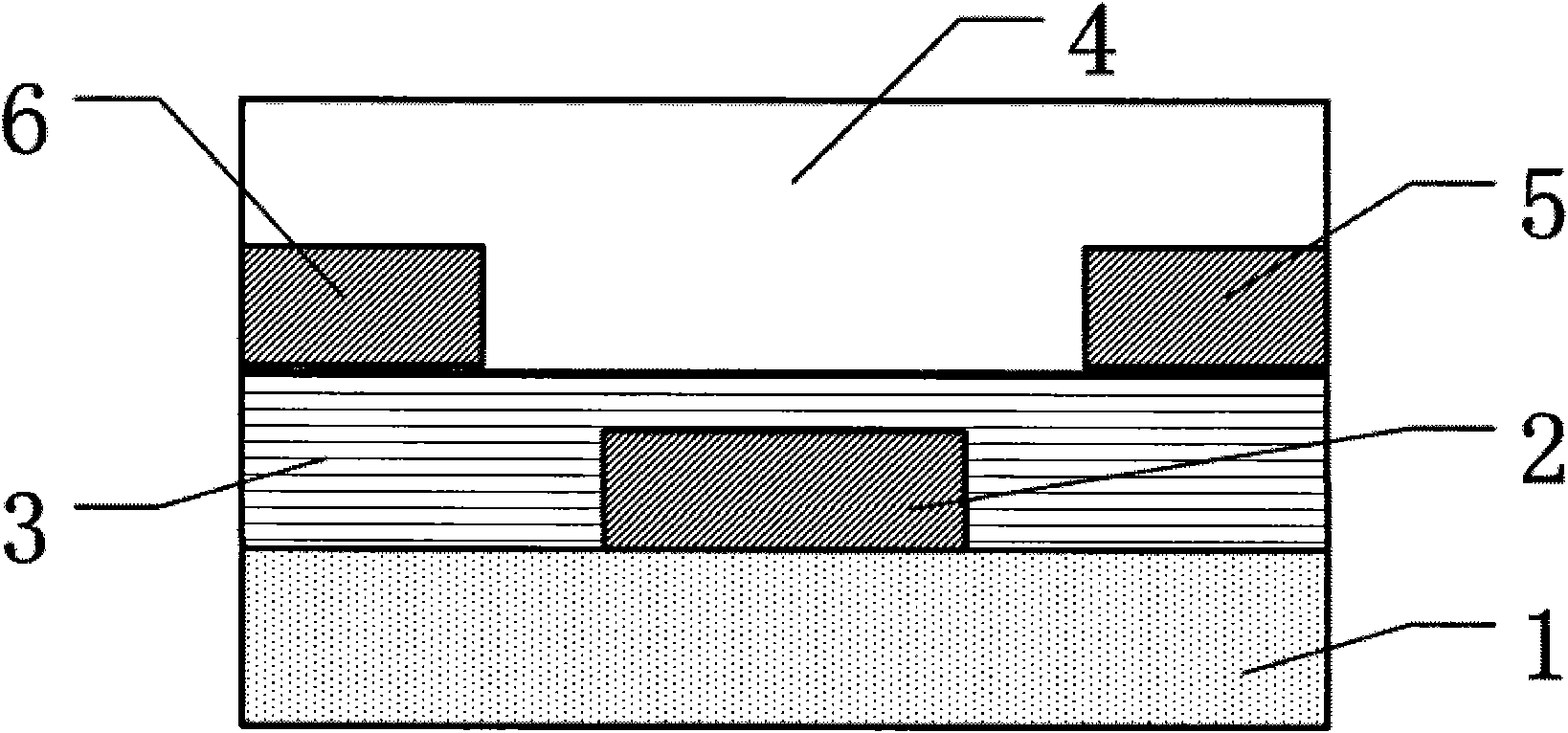

[0032] What is obtained by this preparation method is a bottom-contact quantum dot field effect transistor chiral sensor:

[0033] Step 1, sputtering or evaporating a layer of gate electrode 2 with a thickness of 10nm-500nm on the substrate 1, the gate electrode is composed of one or two of Ta, Ti, Cr, W, Mo, Au or Ag.

[0034] Step 2, sputtering or evaporating a layer of high dielectric constant gate insulating layer 3 with a thickness of 150nm to 500nm, the gate insulating layer is made of SiO 2 、 Ta 2 o 5 、Al 2 o 3 、TiO 2 , BZT, or PZT in one or two forms.

[0035] Step 3, sputtering, inkjet printing or evaporating a layer of source electrode 5 and drain electrode 6 composed of one or two of Au, Ag, Ti, PEDOT:PSS, etc. on the gate insulating layer 3 .

[0036] Step 4, on the gate insulating layer 3 and the source / drain electrodes, a layer of active layer 4 with a thickness of 10 nm to 500 nm is printed by vacuum thermal evaporation, spin coating, inkjet printing or scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com