Extensible oversize light-emitting diode (LED) chip and manufacture method thereof

A light-emitting diode, super-sized technology, used in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

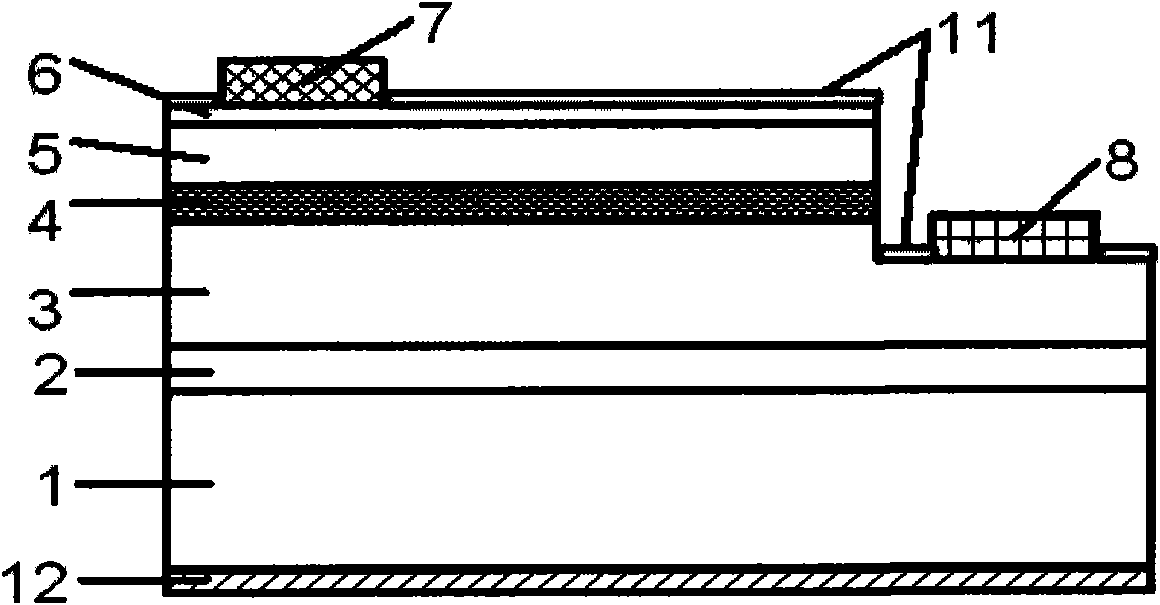

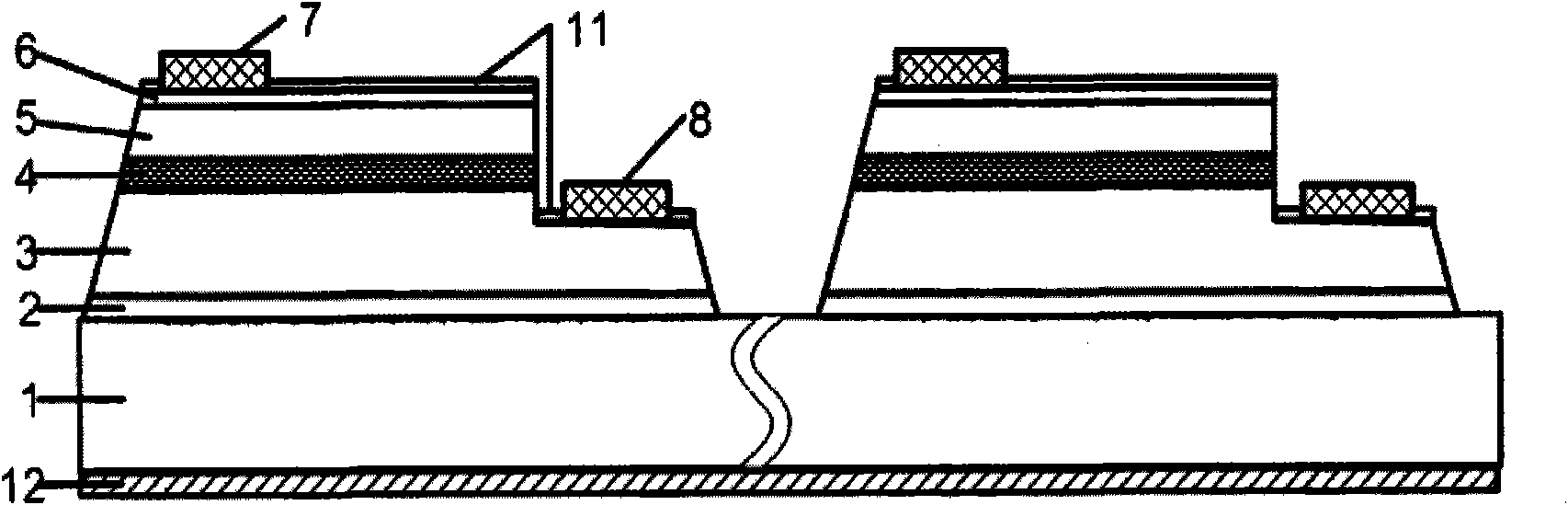

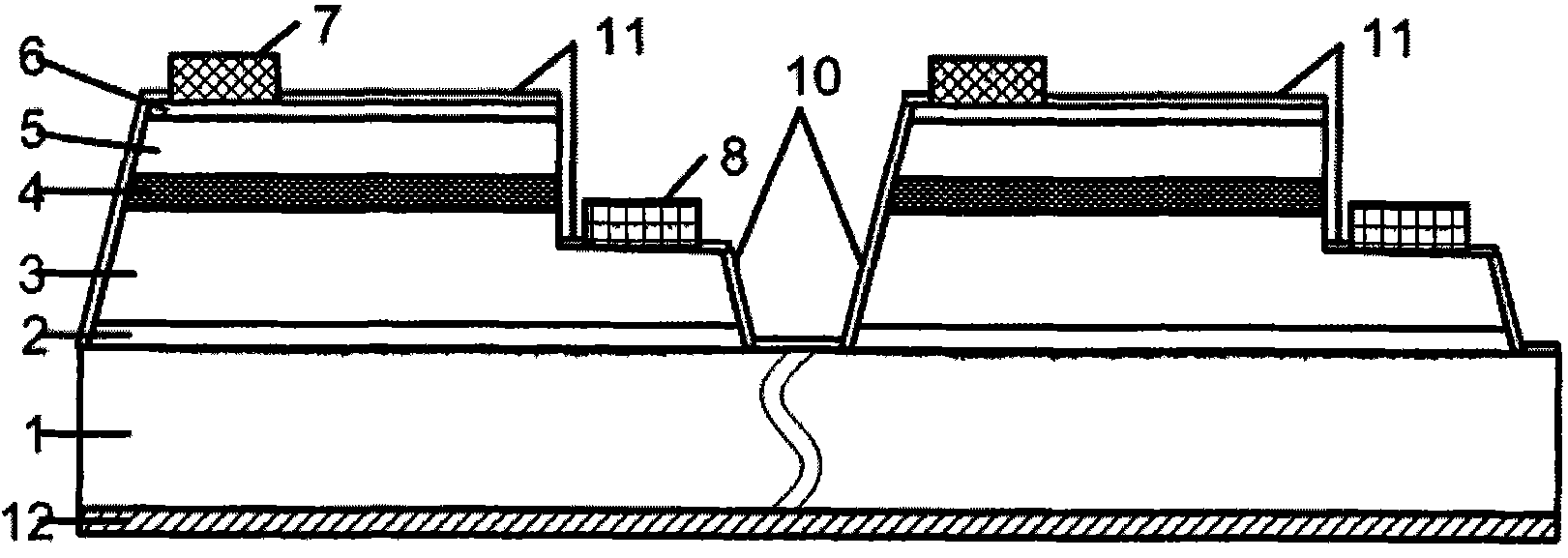

[0025] see figure 1 , figure 2 and image 3 It is a cross-sectional view of an expandable super-large-size light-emitting diode structure of the formal structure of the embodiment, Figure 4 , is the plan view of the expandable super-large-sized light-emitting diode of the formal structure of the embodiment. The shape of the chip is square, and the lateral dimension is 0.3 mm to 500 mm. This embodiment consists of a substrate 1, an epitaxially grown GaN buffer layer 2, an N-type doped GaN layer 3, an active layer 4, a P-type doped GaN layer 5, a current spreading layer 6, and a metal P electrode. 7, a metal N electrode 8, a protective film 11, and a reflective layer 12, and epitaxially grow a GaN buffer layer 2 on a sapphire substrate 1, an N-type doped GaN layer 3, an active layer 4, and a P Type doped gallium nitride layer 5, and then deposit a layer...

Embodiment 2

[0034] Embodiment 2 is the same as Embodiment 1, except that the shape of the chip is parallelogram or circle, and the shape of the groove 9 is comb-like, zig-zag or arc-like, see Figure 5 , Figure 6 , Figure 7 , the cross-section of the trench 9 is a positive trapezoid, and its inclination angle θ is 10° to 80°, and a reflective layer 12 is deposited on the side wall, see Figure 9 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com