Light-emitting diode packaging structure and packaging method thereof

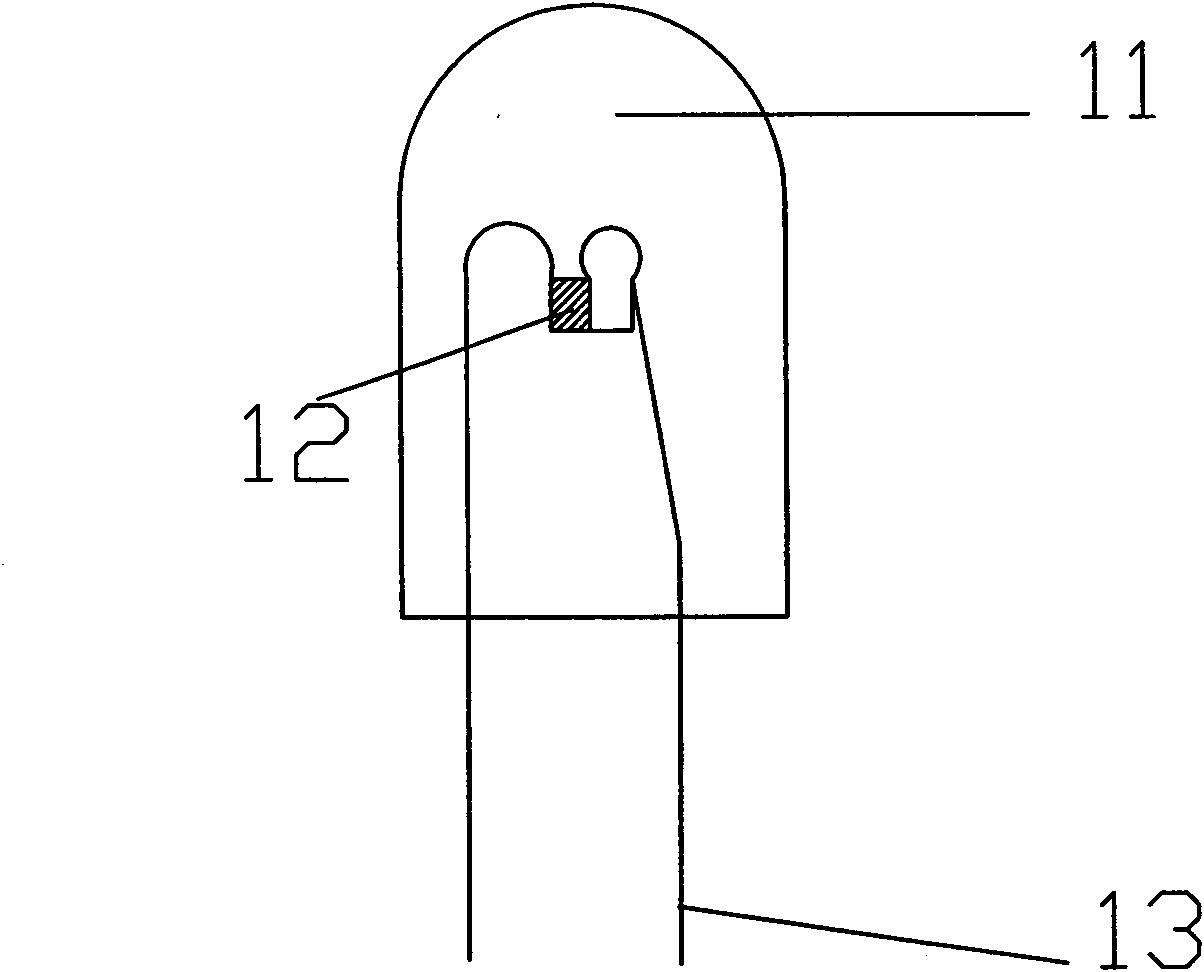

A technology of light-emitting diodes and packaging structures, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., and can solve the problems of small heat transfer area of metal bracket 13, difficult to achieve heat dissipation effect, poor thermal conductivity, etc., to achieve material saving and simple structure , Adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

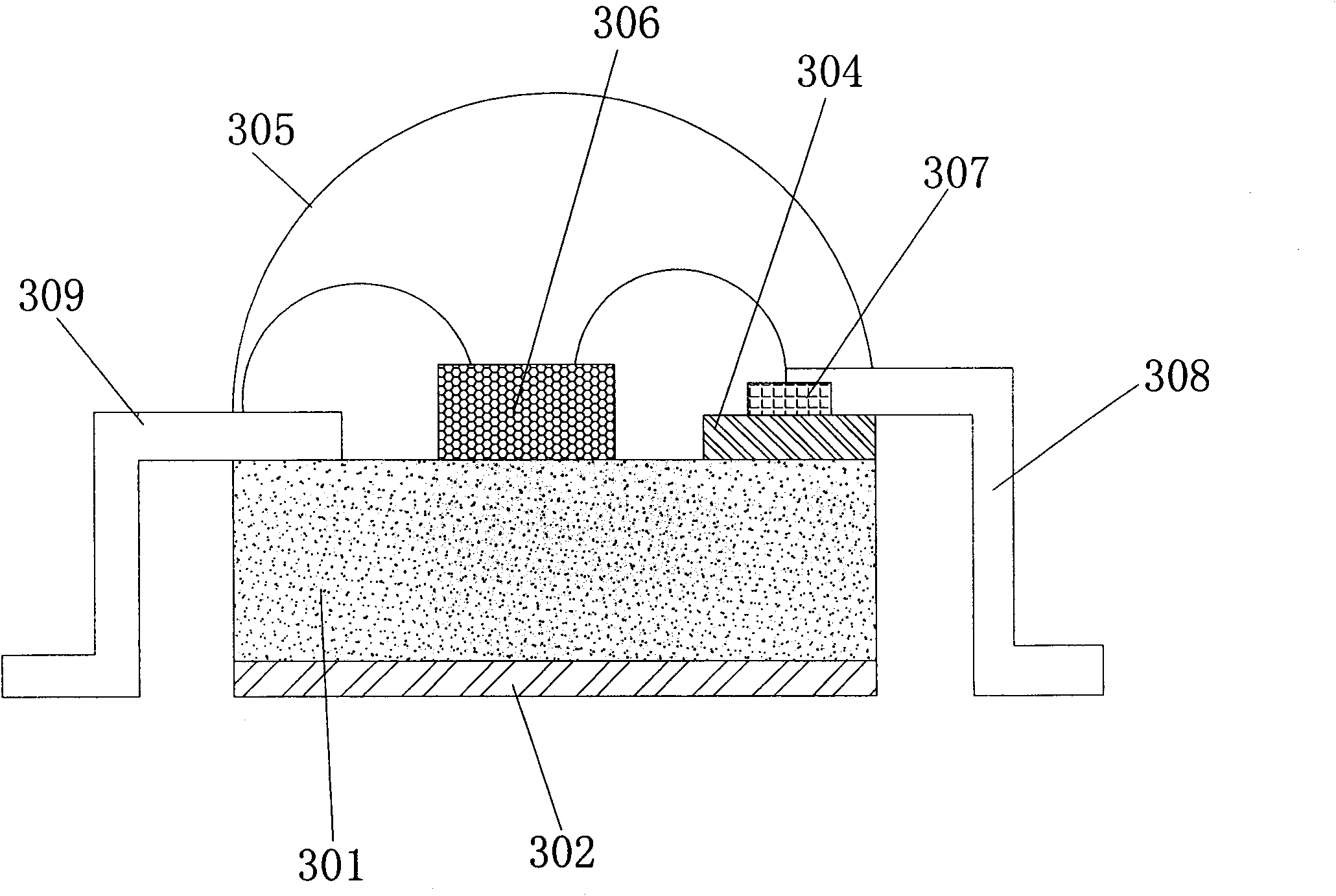

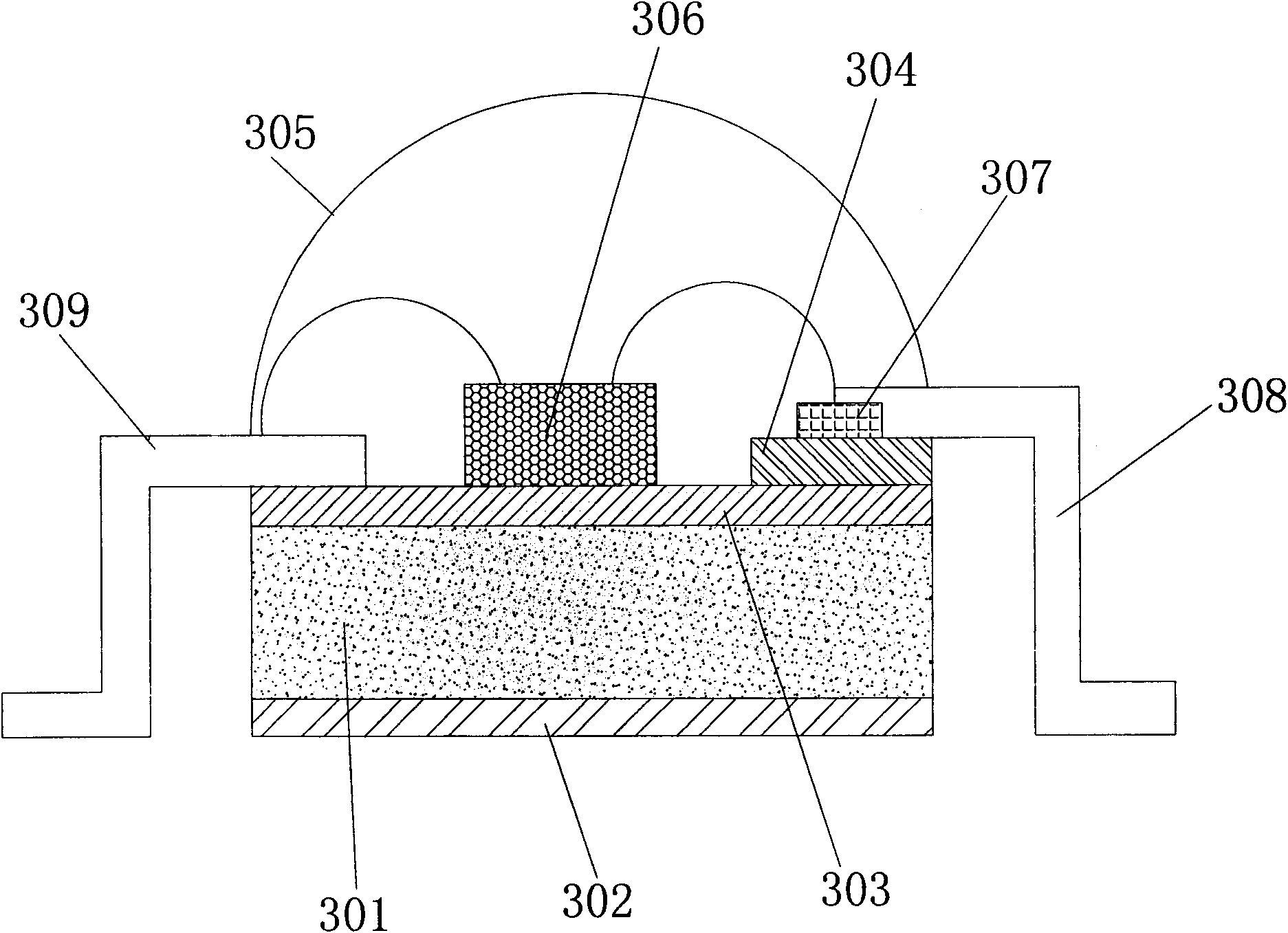

[0047] In Embodiment 2, the bottom of the metal substrate 301 is set as a rough bottom surface, and a layer of ceramic insulating layer (ie, the second insulating layer 302 ) is fabricated on the rough bottom surface of the bottom of the metal substrate by thermal spraying. In this embodiment, the first external electrode 308 and the second external electrode 309 are respectively welded on the metal electrode layer 307 and the metal heat conducting layer 303 by ultrasonic welding or resistance welding. The metal electrode layer 307 is melted and attached to the glass-ceramic insulating layer by means of laser ablation.

[0048] The laser ablation and melting method is used to form the required glass ceramic insulating layer and metal electrode layer, which avoids the overall high-temperature sintering, does not need to use a high-temperature sintering process, saves energy, is environmentally friendly, expands the types of optional metal substrate materials, and is easy to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com