Method for extracting pecan oil by using supercritical carbon dioxide fluid

A pecan oil and carbon dioxide technology is applied in the field of pecan oil extraction and supercritical carbon dioxide fluid extraction of pecan oil, which can solve problems such as unfavorable human health, organic solvent residues in crude oil, and decreased water-soluble protein content, etc. The effect of preventing poisoning to the human body and pollution to the environment, preventing poisoning and pollution to the environment, and avoiding the residual of solvent toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

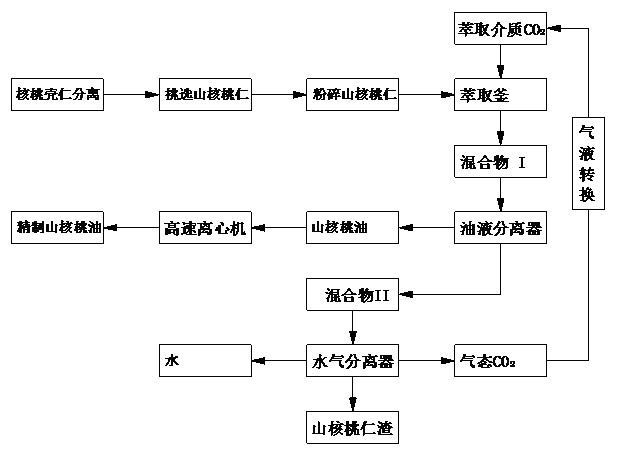

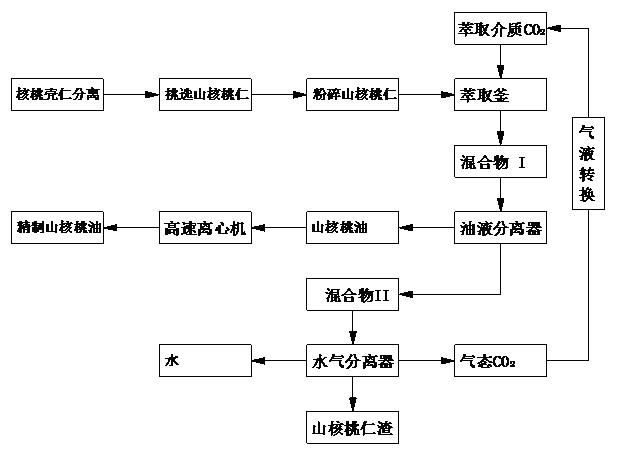

[0017] Embodiment 1: refer to figure 1 . The method that supercritical carbon dioxide fluid extracts hickory nut oil comprises the following steps:

[0018] a. The hickory nuts are shelled by a shell breaking machine, and after the shells and kernels are separated, the hickory kernels are selected;

[0019] b. Put the hickory kernels into a turbo grinder, and grind the hickory kernels to a fineness of 20 meshes;

[0020] c. Put the crushed hickory kernels into the extraction kettle, measure the carbon dioxide of the extraction medium into the extraction kettle, control the supercritical extraction temperature to 45°C, the supercritical extraction pressure to 30Mpa, and the carbon dioxide flow rate to 500 liters / Hour, extraction time 2.5 hours, generate the mixture I of degreasing hickory nut kernel, liquid carbon dioxide and hickory nut oil;

[0021] d. Put the mixture I in the above-mentioned extraction tank into the oil separator, control the separation pressure to 8 Mpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com