Brake pad polishing machine

A technology for brake pads and polishing machines, applied in the field of polishing technology, can solve the problems of accelerated wear of brake discs and brake pads, hidden dangers of normal use of braking systems, hidden dangers of motor vehicle safety, etc., so as to achieve less electricity bills and save equipment investment costs. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

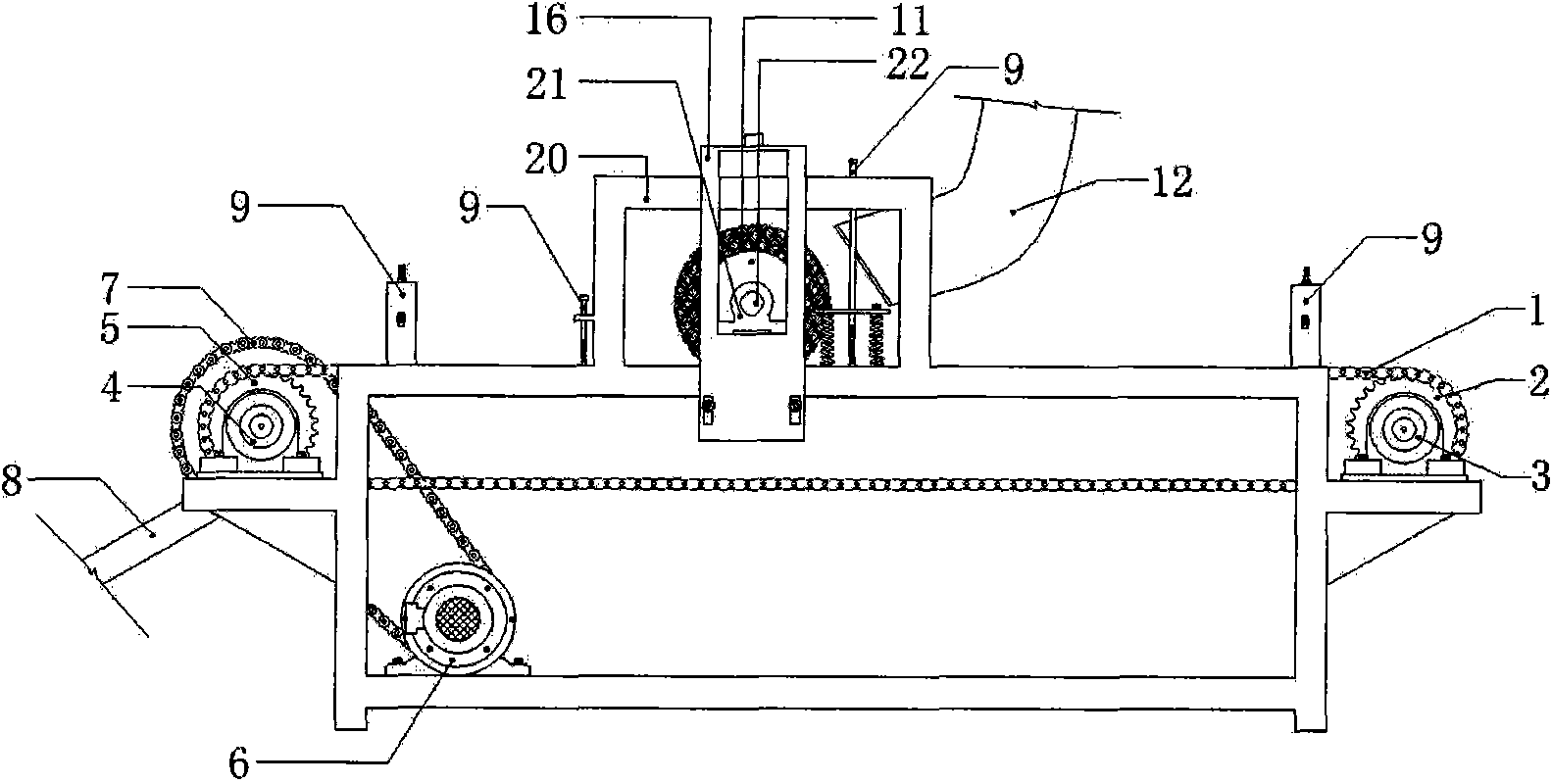

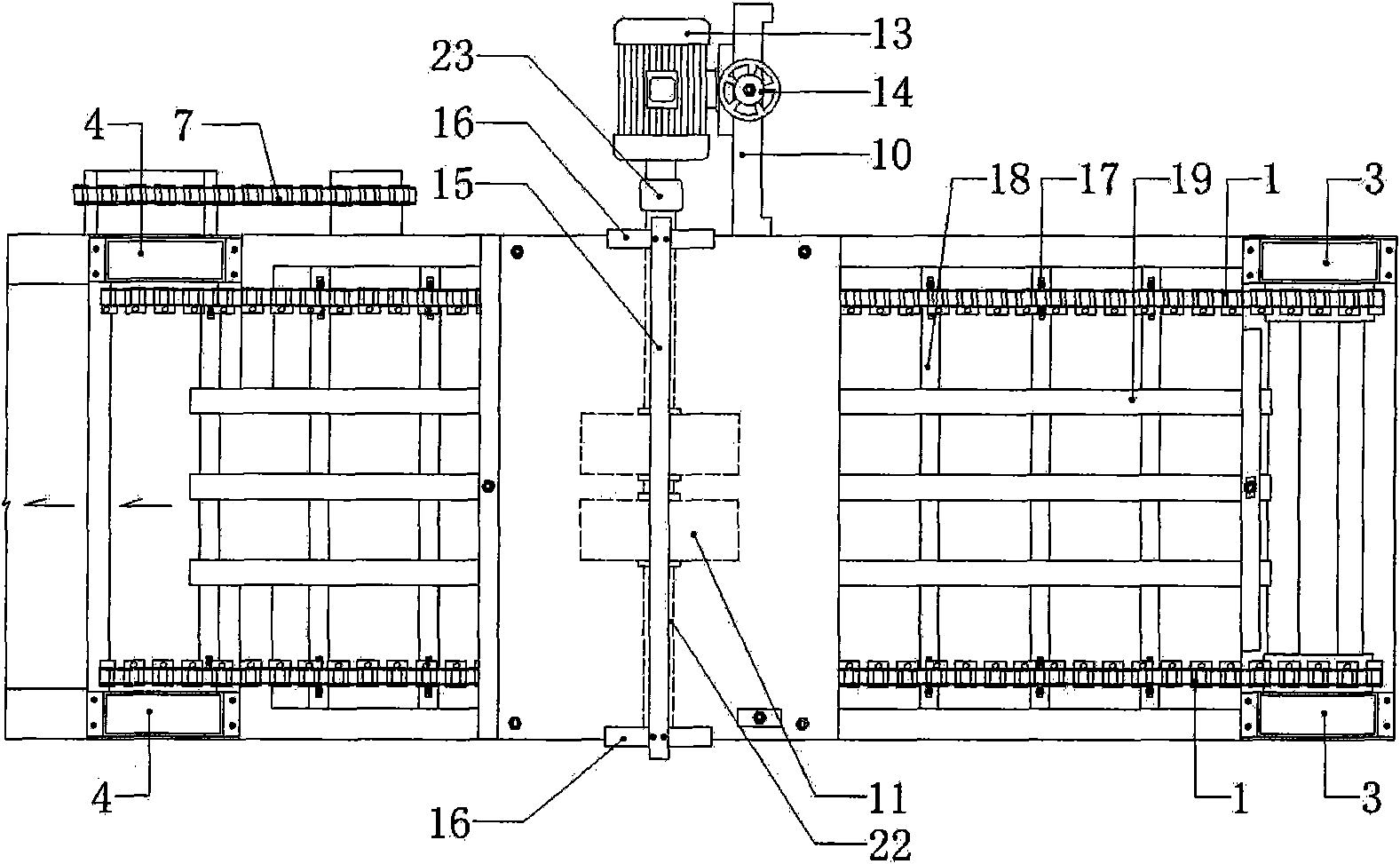

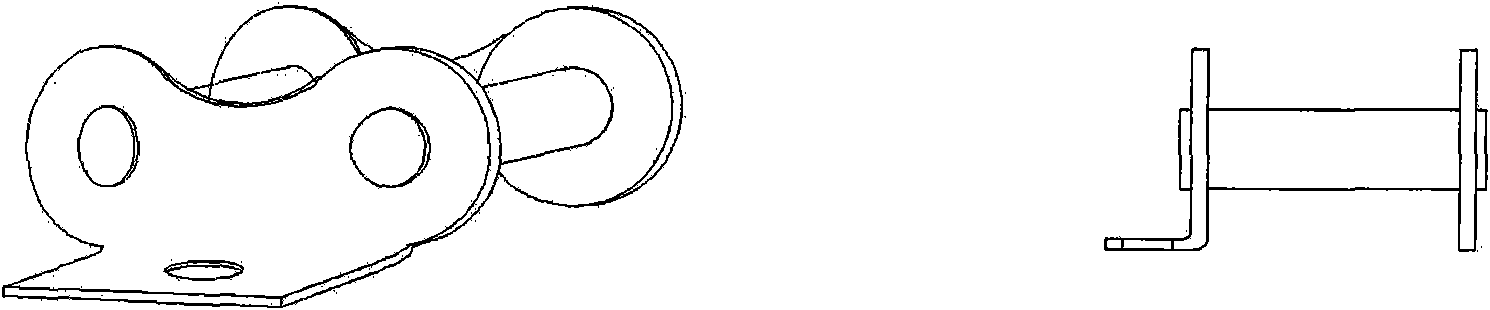

[0013] The brake pad polishing machine provided by the present invention mainly uses two transmission chains 1 on both sides of the polishing machine as a conveying device, and the transmission chains 1 on both sides are driven by the driving sprocket 5 to drive the driven sprocket 2 to perform plane rotation. Sprocket 5 and driven sprocket 2 are fixedly mounted on the two ends of the polisher frame by bearing blocks 4 and 3 respectively. The chain link 17 of chain 1 all adopts the special-shaped chain link of special structure (see Figure three shown), there is a reserved bolt hole on the inner side of the special-shaped chain link 17 Type connecting plate, the special-shaped chain links corresponding to the two sides are fixed with bolts at regular intervals to push the plate baffle plate 18, which is used to push the placed brake pad forward. , the push piece baffle can also play the role of backward limit.

[0014] The three limiting flat irons 19 above the push piece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com