Method for preparing water-soluble NaYF4 up-conversion luminescent material

A luminescent material, water-soluble technology, applied in luminescent materials, chemical instruments and methods, rare earth metal compounds, etc., can solve problems such as difficult to disperse, achieve the effects of pollution-free by-products, low equipment requirements, and easy scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

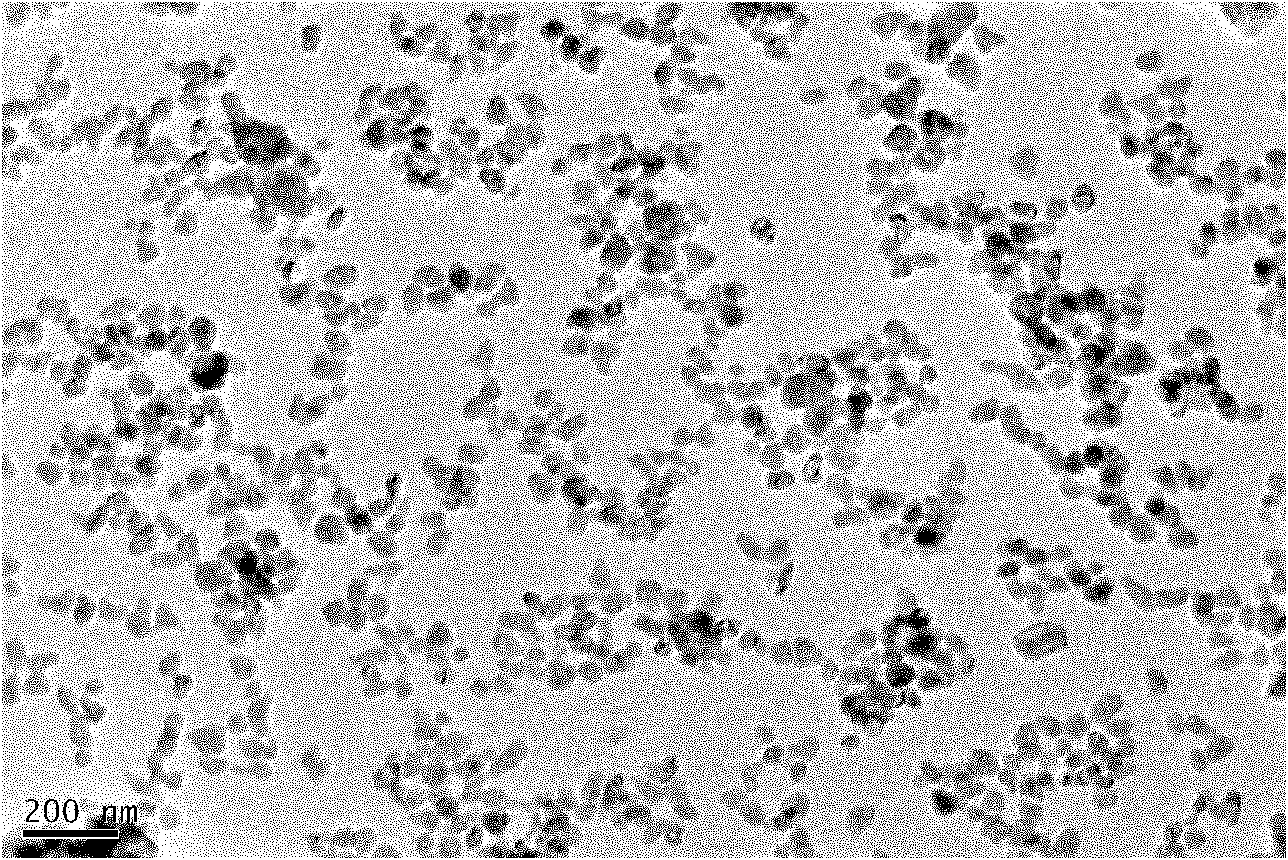

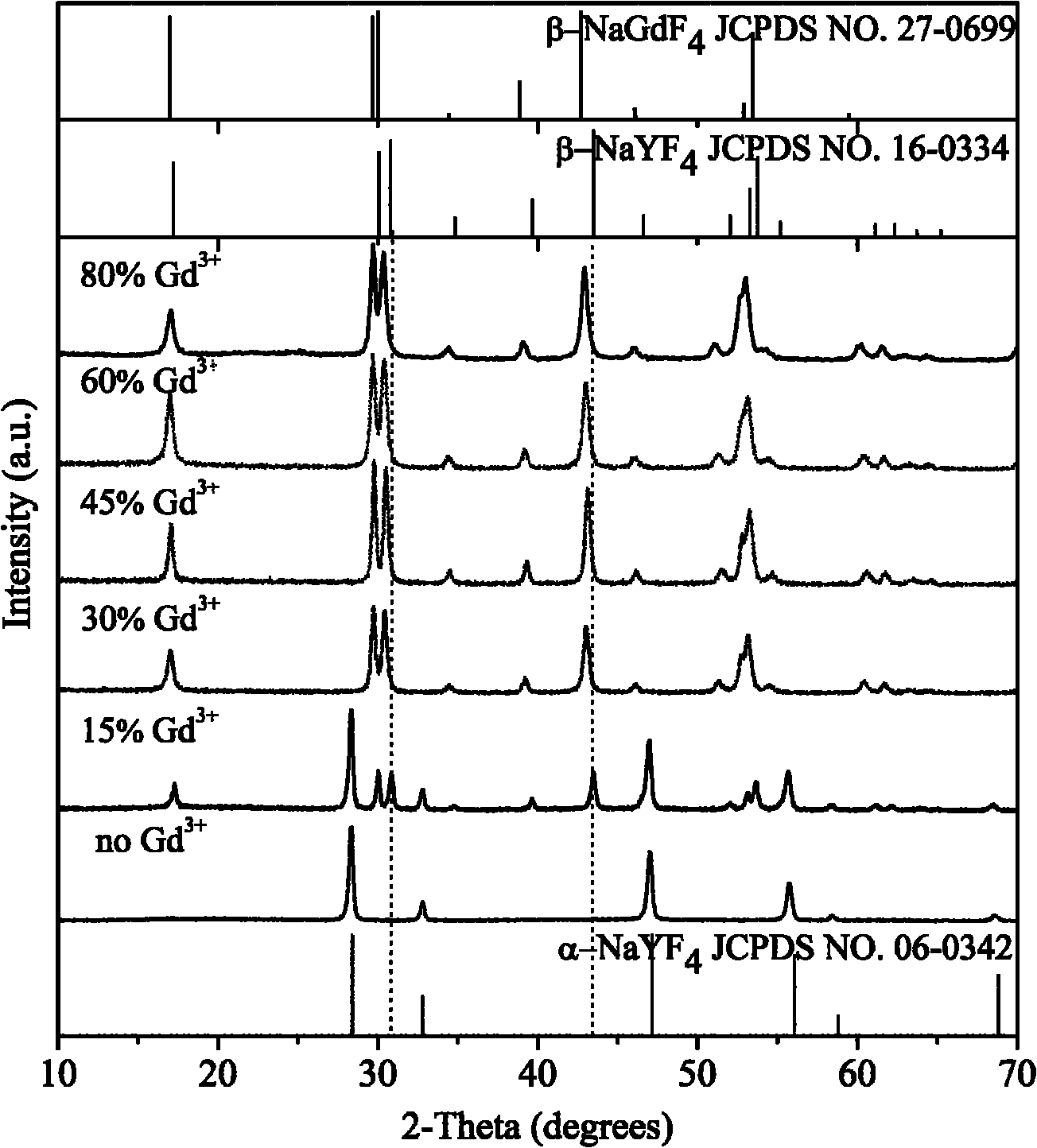

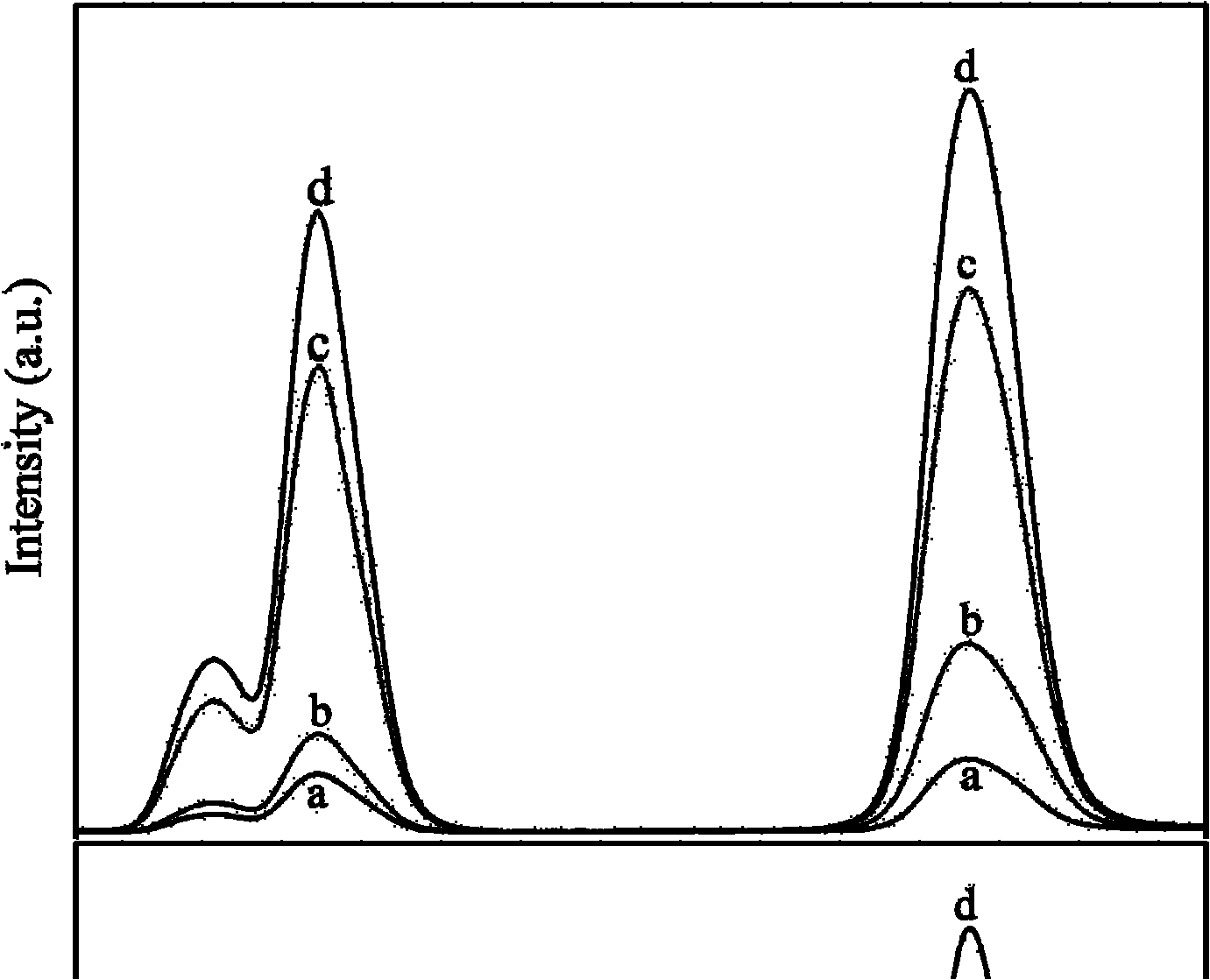

Embodiment 1

[0019] (A) Weigh 25mmol of NaF solid in a beaker, then add 20mL of ethylene glycol, dissolve and stir under ultrasound for 20 minutes at room temperature; (B) Add 1g of polyvinylpyrrolidone K-30 to 20mL of ethylene glycol (PVP), ultrasonic dissolving and stirring at room temperature for 20 minutes; after the dispersion is complete, add 3mmol solid LnCl 3 (Ln=80mol%Y+18mol%Yb+2mol%Er), dissolve with ultrasonic stirring for about 20 minutes. Under stirring conditions, A was added to B, followed by ultrasonic stirring for 30 minutes. Finally, it was transferred to an autoclave and reacted at 140°C for 12 hours. After the reaction, the water-soluble NaYF with adjustable crystal phase and luminescence can be obtained by centrifugal drying 4 Up-conversion luminescent material.

Embodiment 2

[0021] (A) Weigh 25mmol of NaF solid in a beaker, then add 20mL of ethylene glycol, dissolve and stir under ultrasound for 20 minutes at room temperature; (B) Add 1g of polyvinylpyrrolidone K-30 to 20mL of ethylene glycol (PVP), ultrasonic dissolving and stirring at room temperature for 20 minutes; after the dispersion is complete, add 3mmol solid LnCl 3 (80mol% Y+18mol% Yb+2mol% Er), dissolve with ultrasonic stirring for about 20 minutes. Under stirring conditions, A was added to B, followed by ultrasonic stirring for 30 minutes. Finally, it was transferred to an autoclave and reacted at 180°C for 12 hours. After the reaction, the water-soluble NaYF with adjustable crystal phase and luminescence can be obtained by centrifugal drying 4 Up-conversion luminescent material.

Embodiment 3

[0023] (A) Weigh 25mmol of NaF solid in a beaker, then add 20mL of ethylene glycol, dissolve and stir under ultrasound for 20 minutes at room temperature; (B) Add 1g of polyvinylpyrrolidone K-30 to 20mL of ethylene glycol (PVP), ultrasonic dissolving and stirring at room temperature for 20 minutes; after the dispersion is complete, add 3mmol solid LnCl 3 (80mol% Y+18mol% Yb+2mol% Er), dissolve with ultrasonic stirring for about 20 minutes. Under stirring conditions, A was added to B, followed by ultrasonic stirring for 30 minutes. Finally, it was transferred to an autoclave and reacted at 220°C for 12 hours. After the reaction, the water-soluble NaYF with adjustable crystal phase and luminescence can be obtained by centrifugal drying 4 Up-conversion luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com