Bismuth calcium titanate-based luminous piezoelectric ceramic material and preparation method

A bismuth calcium titanate-based, piezoelectric ceramic technology, applied in the field of electronic functional materials, to achieve excellent photoelectric performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

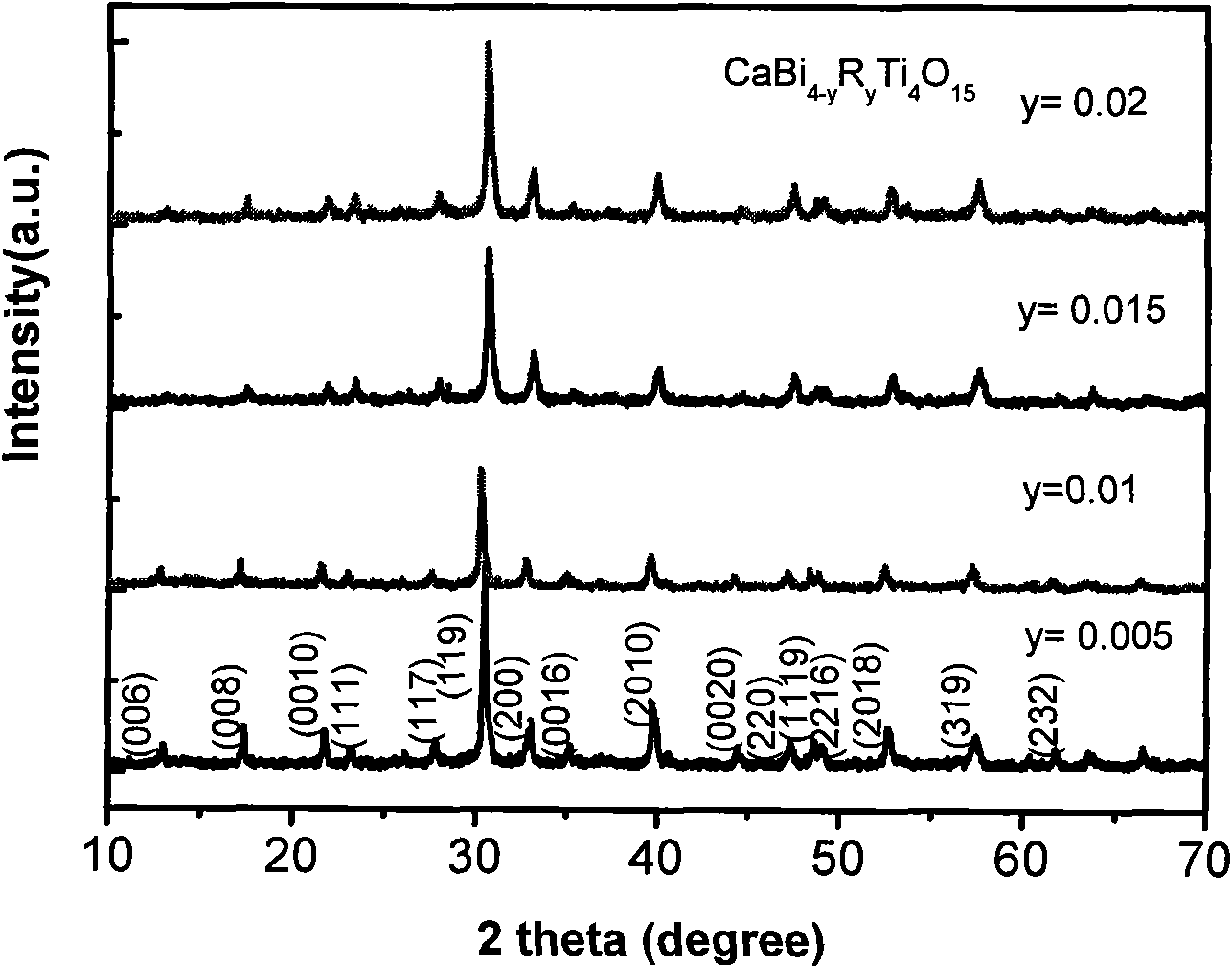

[0029] to prepare CaBi 4-0.005 PR 0.005 Ti 4 o 15 、CaBi 4-0.01 PR 0.01 Ti 4 o 15 、CaBi 4-0.015 PR 0.015 Ti 4 o 15 、CaBi 4-0.02 PR 0.02 Ti 4 o 15 For example, the raw material is CaCO 3 , Bi 2 o 3 ,TiO 2 , Pr 6 o 11 , according to the general chemical formula CaBi 4-0.005 PR 0.005 Ti 4 o 15 、CaBi 4-0.01 PR 0.01 Ti 4 o 15 、CaBi 4-0.015 PR 0.015 Ti 4 o 15 、CaBi 4-0.02 PR 0.02 Ti 4 o 15 The stoichiometric ratio of Ca, Bi, Ti and R in the formula is to weigh the raw materials, add absolute ethanol or deionized water after weighing the raw materials, grind them in a mortar and mix well to get powder A 1 、A 2 、A 3 、A 4 , wherein the mass ratio of the absolute ethanol or deionized water to the raw material mixture is 1-3:1; the mass ratio of the ball mill zirconia ball to the raw material mixture is 1-1.5:1. Powder A 1 、A 2 、A 3 、A 4 Place them in alumina crucibles for pre-firing respectively. The pre-firing temperature is 850°C, and the heat...

Embodiment 2

[0036] to prepare Ca 1.5 Bi 4-0.01 PR 0.01 Ti 4.5 o 16.5 For example, the raw material is CaCO 3 , Bi 2 o 3 ,TiO 2 , Pr 6 o 11 , by formula Ca 1.5 Bi 4-0.01 PR 0.01 Ti 4 o 16.5 Ratio of elements The selected raw materials were weighed, the pre-firing temperature was 900°C, the holding temperature of the ceramic green sheet after debonding treatment was 1200°C, and the rest of the experimental conditions were the same as in Example 1.

[0037] It can be seen from the test that the final sample obtained in this example is the luminescent piezoelectric ceramic material Ca in the present invention. 1.5 Bi 4-0.01 PR 0.01 Ti 4.5 o 16.5 ;

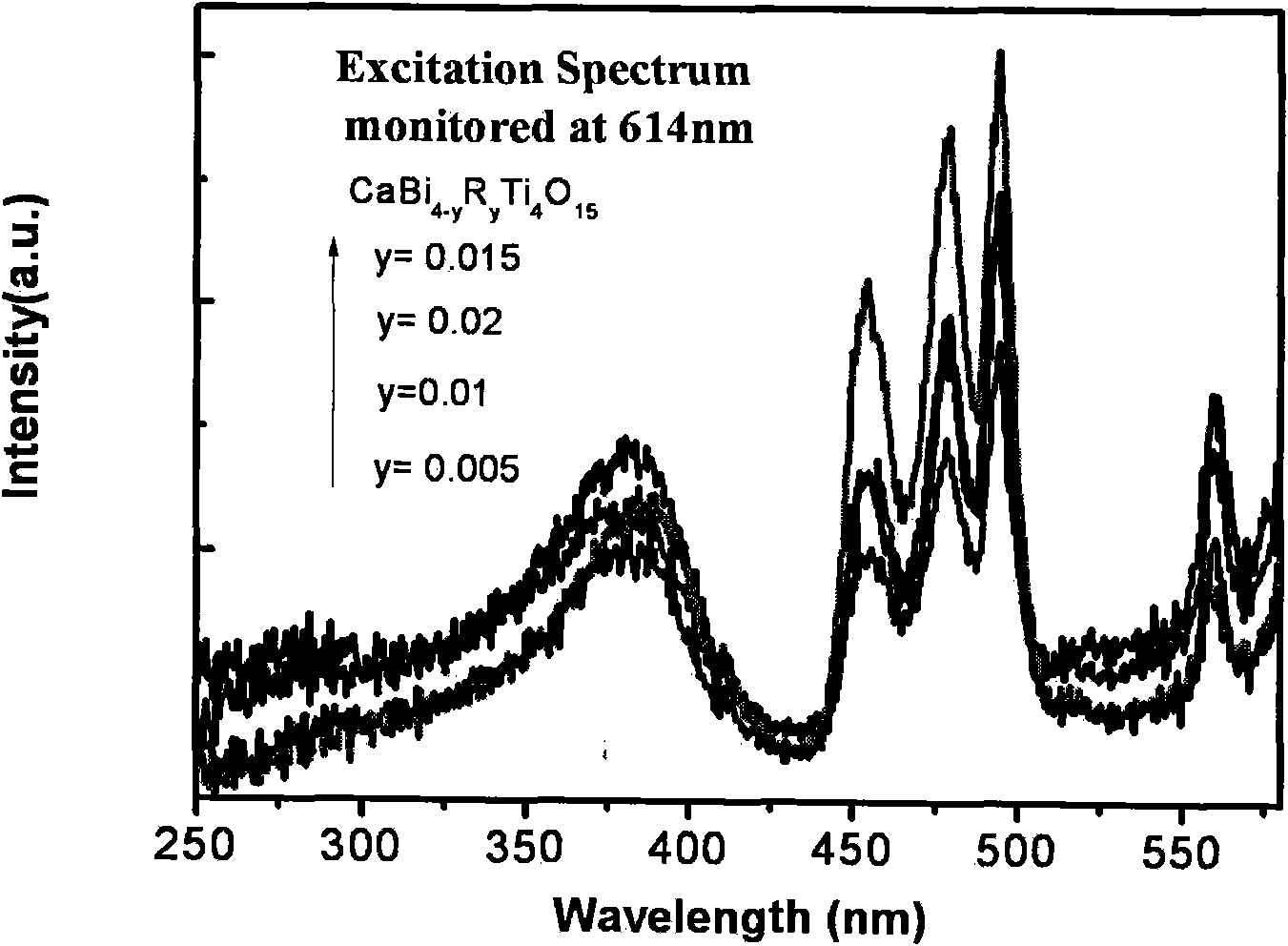

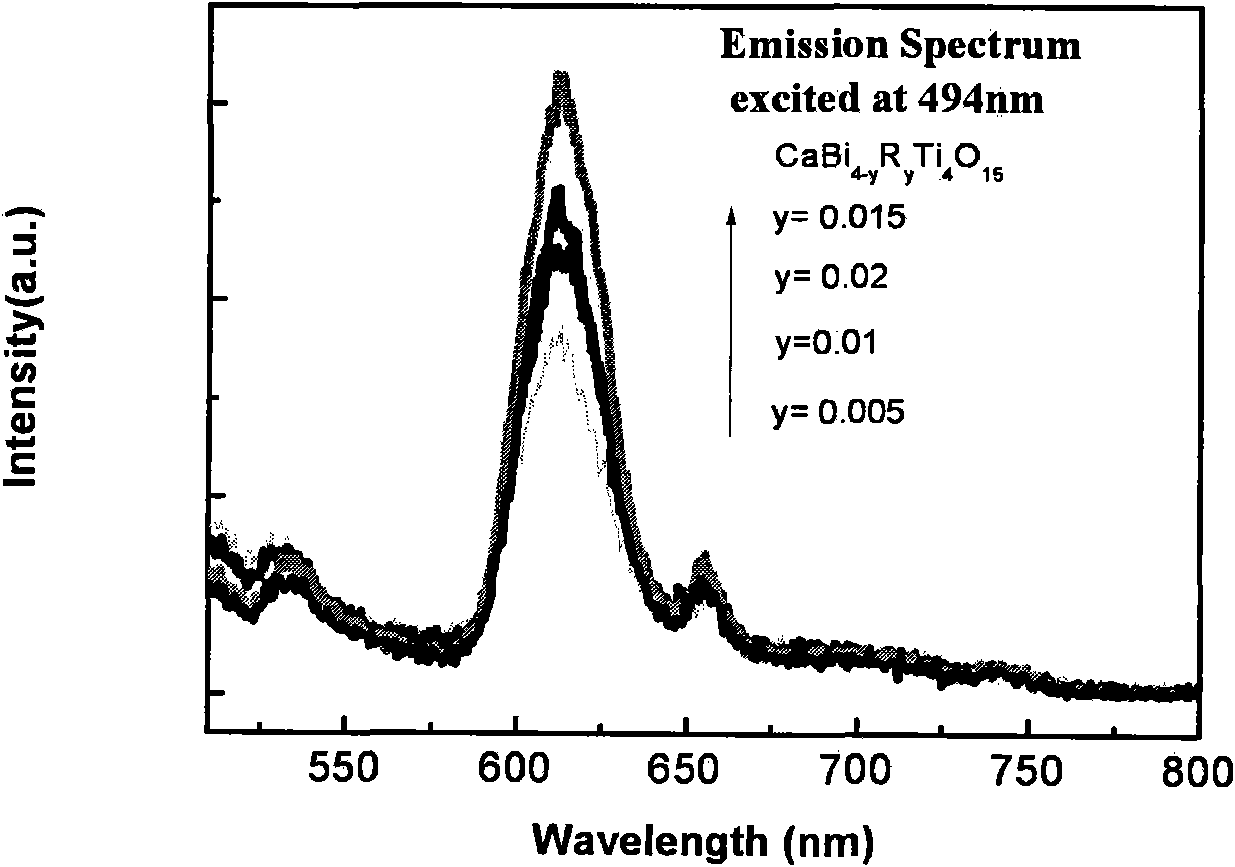

[0038] All the luminescent piezoelectric ceramic materials in this embodiment can be excited by waves in three bands of ultraviolet light (300nm-430nm), blue light (440nm-510nm) or green light (550nm-570nm).

Embodiment 3

[0040] to prepare Ca 2 Bi 4-0.02 PR 0.02 Ti 5 o 18 For example, the raw material is CaCO 3 , Bi 2 o 3 ,TiO 2 , Pr 6 o 11 , by formula Ca 2 Bi 4-0.02 PR 0.02 Ti 5 o 18 Ratio of elements The selected raw materials were weighed, the pre-firing temperature was 950°C, the holding temperature of the ceramic green sheet after debonding treatment was 1200°C, and the rest of the experimental conditions were the same as in Example 1.

[0041] It can be seen through detection that the final sample obtained in this embodiment is the luminescent piezoelectric ceramic material Ca in the present invention. 2 Bi 4-0.02 PR 0.02 Ti 5 o 18 ;

[0042] All the luminescent piezoelectric ceramic materials in this embodiment can be excited by waves in three bands of ultraviolet light (300nm-430nm), blue light (440nm-510nm) or green light (550nm-570nm).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com