Product confocal-scanning detection method with high spatial resolution

A technology with high spatial resolution and detection method, applied in the field of microscopic imaging and microscopic measurement, can solve the problem of insignificant three-dimensional super-resolution effect, and achieve the effect of improving spatial imaging detection ability, lateral resolution, and spatial resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

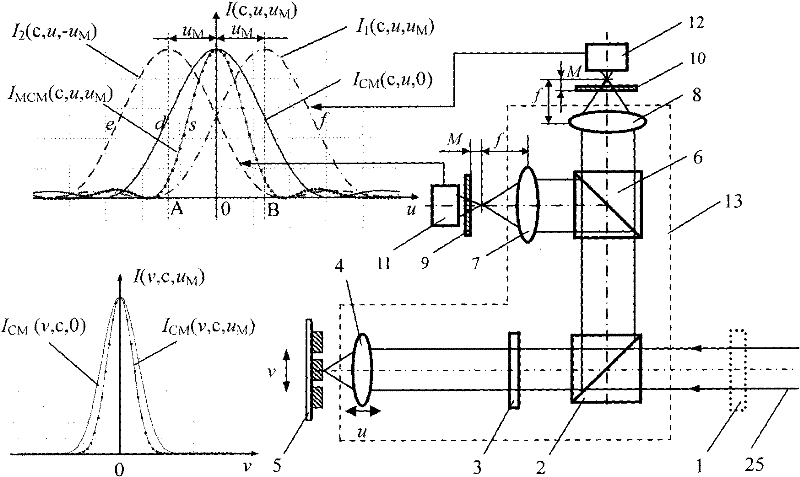

[0044] As one of the embodiments of the present invention, the product confocal microscopic detection method is used to improve the spatial resolution below, and the product confocal microscopic detection method with high spatial resolution of the present invention is further described as follows:

[0045] Such as Figure 4 As shown, the light source 14 emits a laser beam with a wavelength of λ=633nm, and then expands it into a Gaussian beam of φ4mm through a collimator beam expander 15, passes through a spatial filtering pinhole 16, and makes it a point light source, and the parallel light after beam expansion Transmitted and reflected by the polarizing beam splitter 2, wherein the p light transmitted by the polarizing beam splitter 2 is converged on the surface of the measured sample 5 through the 1 / 4 wave plate 3 and the measuring objective lens 4, and then the light reflected by the measured sample 5 moves along the Going back the same way, after passing through the 1 / 4 wa...

Embodiment 2

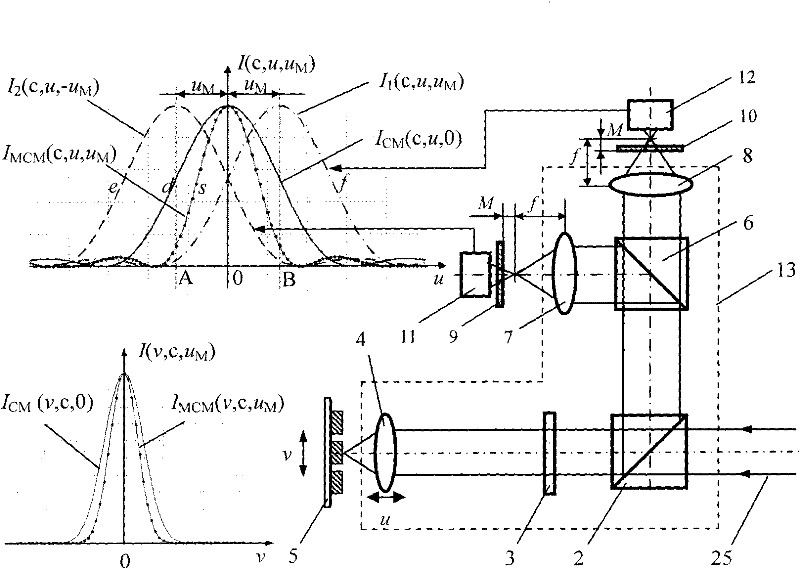

[0068] The product confocal microscopic detection method of shaping ring light formula improves the spatial resolution as the second embodiment of the present invention below, and the product confocal microscopic detection method with high spatial resolution of the present invention is further described as follows:

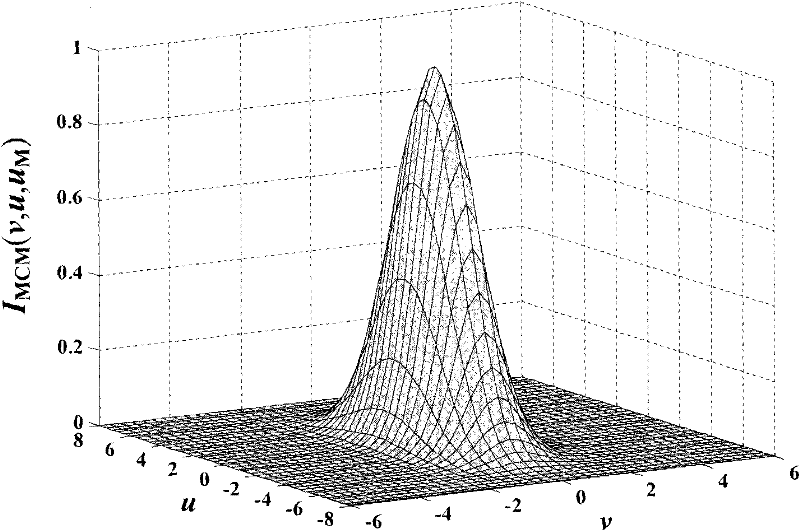

[0069] Such as Figure 7 As shown, the dotted frame part is the double receiving optical path arrangement 13 of the product confocal microscope, and the optical super-resolution device is the shaping binary optical device 24 . The light intensity response function I(v,u,u) of a reflective confocal microscope with a pupil function P(ρ) under monochromatic illumination M )for:

[0070] I ( v , u , u M ) = | ∫ ϵ 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com