How to make a mos transistor

A technology of MOS transistors and manufacturing methods, which is applied in the field of MOS transistor manufacturing, and can solve problems such as difficulty in forming ultra-shallow junctions and difficulty in lateral diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

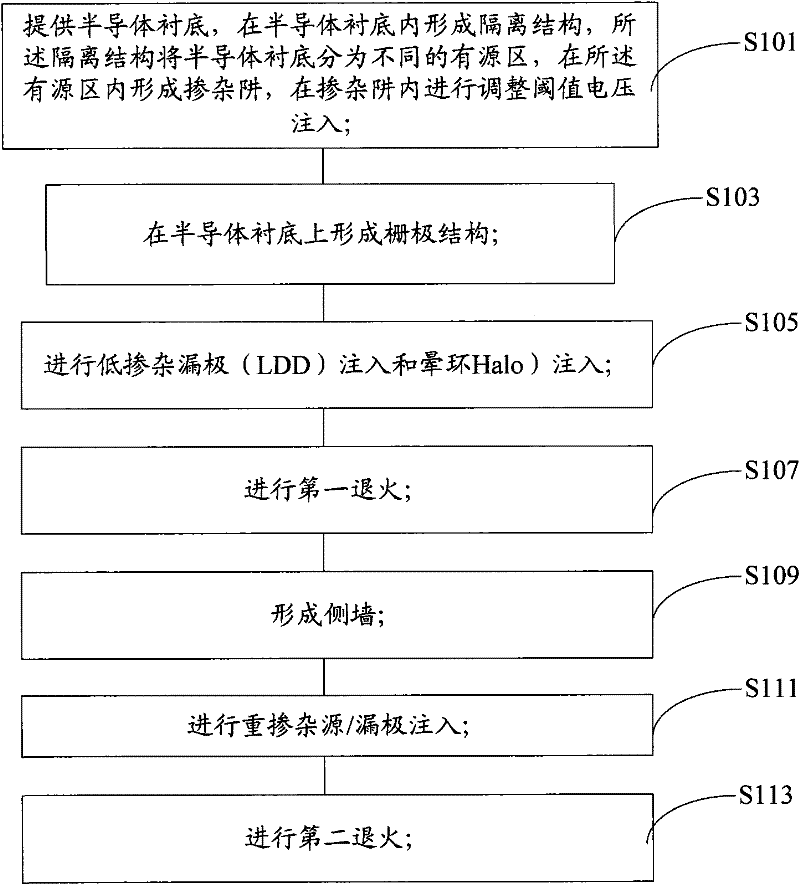

[0028] As mentioned above, based on the above-mentioned experimental research and theoretical derivation, the inventors of the present invention found that the prior art LDD implanted region needs to undergo at least two anneals, which makes it difficult to form ultra-shallow junctions and to control lateral diffusion. Based on the above findings, the inventors of the present invention annealed the LDD implanted region only once by changing the process, and improved the annealing process to reduce the diffusion of the LDD implanted ions in the depth direction. The technology reduces the dose or energy of LDD implantation to form shallow junctions, so it can prevent the ion diffusion area of the LDD implantation area from being too large, which is conducive to the formation of ultra-shallow junctions; at the same time, because the implantation energy and dose are not reduced, the LDD implantation area can be kept relatively small. Low resistance, higher drain saturation curren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com