High-efficiency enzymatic biological fuel battery cathode and preparation method thereof

A biofuel cell and cathode technology, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of unsatisfactory demand and low current efficiency, and achieve excellent catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the purification of laccase

[0021] Dissolve 50mg of laccase (Trametes Versicolor E.C.1.10.3.2, 23.76U / mg) in 500μL of 0.1M phosphate buffer solution (pH 6.0) and transfer to a dialysis bag, and soak the dialysis bag in fresh 0.1M phosphate buffer solution (pH6.0) for 4 hours with stirring and dialysis, then moved to another fresh 0.1M phosphate buffer solution (pH6.0) and stirred for 4 hours, and thus cycled for 1-2 days. Then add ammonium sulfate to the solution in the bag until it is saturated, and a precipitate is precipitated, and then the suspension is centrifuged at 5000 rpm for 10 minutes; the resulting precipitate is dissolved in about 500 μL of 0.1M phosphate buffer solution (pH6.0) , then saturated with ammonium sulfate, and precipitates were separated out again; centrifuged again to obtain precipitates, and the resulting precipitates were dissolved in 300 μL of 0.1M phosphate buffer solution (pH6.0) and put into dialysis tubes, and concentrate...

Embodiment 2

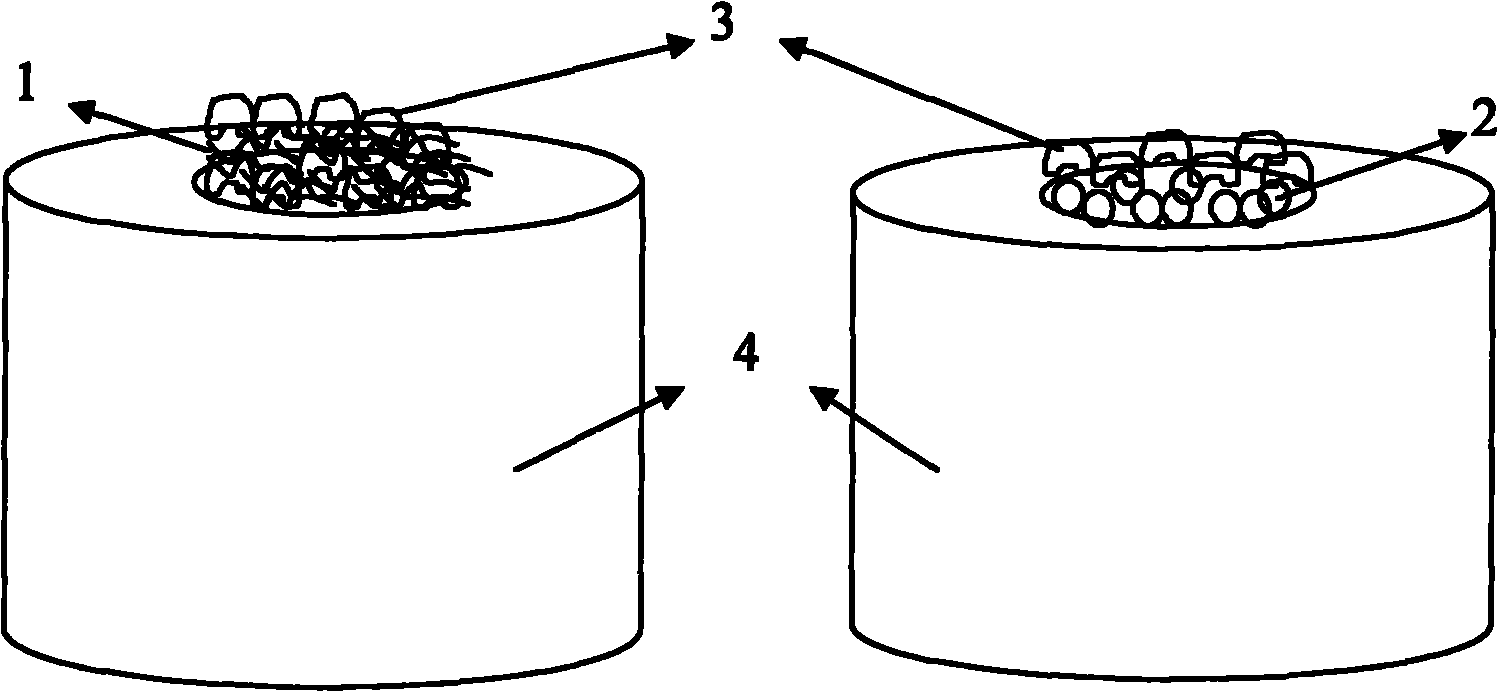

[0022] Embodiment 2, the preparation of high-efficiency enzyme-type biofuel cell cathode

[0023] Continuously sonicate 2mg of carbon nanotubes (Shenzhen Nanoport Co., Ltd., diameter 2 , Ultrasonic frequency is 40kHz) 1 hour, dispersion treatment forms the suspension of 4mg per milliliter, takes 3 μ L of suspension and coats on the glassy carbon substrate electrode of 0.07 square centimeters, dries in the air, forms the carbon nanomaterial layer. Laccase needs to be purified before use, and the specific steps are as described in Example 1. Mix 100 μL of 1000 U / ml laccase (Trametes Versicolor E.C.1.10.3.2, 23.76 U / mg) solution obtained after purification with 20 μL ethanol to obtain a 100 U laccase mixture, and apply 1.5 μL of the laccase mixture on the carbon nanometer On the material layer, the enzyme layer is obtained by drying at room temperature, and the preparation of the high-efficiency enzyme-type biofuel cell cathode is completed.

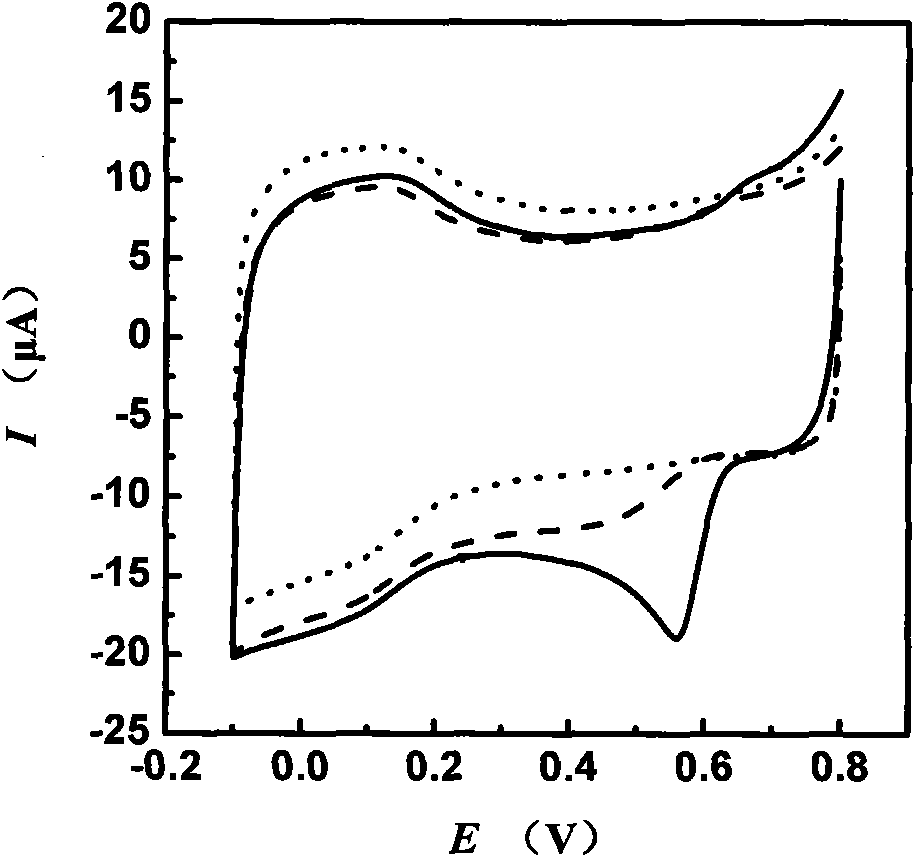

[0024] The oxygen reduction perform...

Embodiment 3

[0025] Embodiment 3, the preparation of high-efficiency enzyme-type biofuel cell cathode

[0026] Continuously sonicate 1 mg of carbon nanospheres (synthesized by the Institute of Chemistry, Chinese Academy of Sciences, 0.5 μm in diameter, reference: Macromolecular Chemistry and Physics 207(18): 1633-1639) in 1 mL of dimethylformamide (ultrasonic intensity is about 1w / cm 2 , Ultrasonic frequency is 40kHz) 0.1 hour, dispersion treatment forms the suspension of 1mg per milliliter, takes 3.5 μ L of suspension and is coated on the glassy carbon substrate electrode of 0.07 square centimeters, dries in air, forms the carbon nano material layer; Mix 60 μL of 1000 U / ml bilirubin oxidase (BOD, E.C.1.10.3.2, from Myrothecium verrucaria) solution with 20 μL acetone to obtain a mixture containing 60 U bilirubin oxidase, take 1.8 μL of bilirubin oxidase and mix The solution is coated on the carbon nanomaterial layer, and dried at room temperature to obtain an enzyme layer, thereby comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com