Washing separation device containing powder block material and separation method thereof

A block material and separation device technology, applied in the fields of material separation, mining, and metallurgy, can solve the problems of high operating costs, increased cost of blast furnace ironmaking, long washing time, etc., to reduce system occupation and investment, and benefit Sedimentation and concentration, to ensure the effect of effective sedimentation and concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

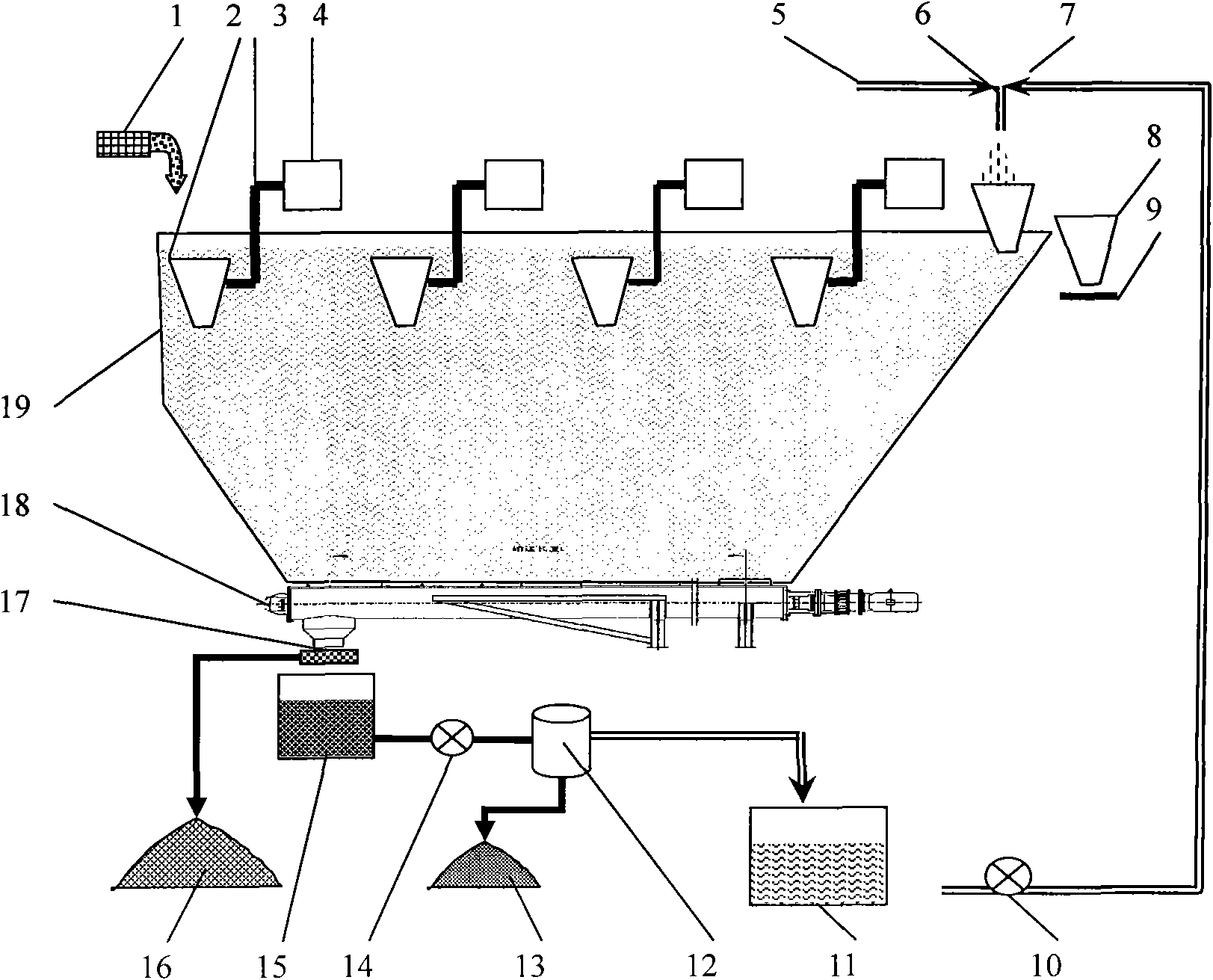

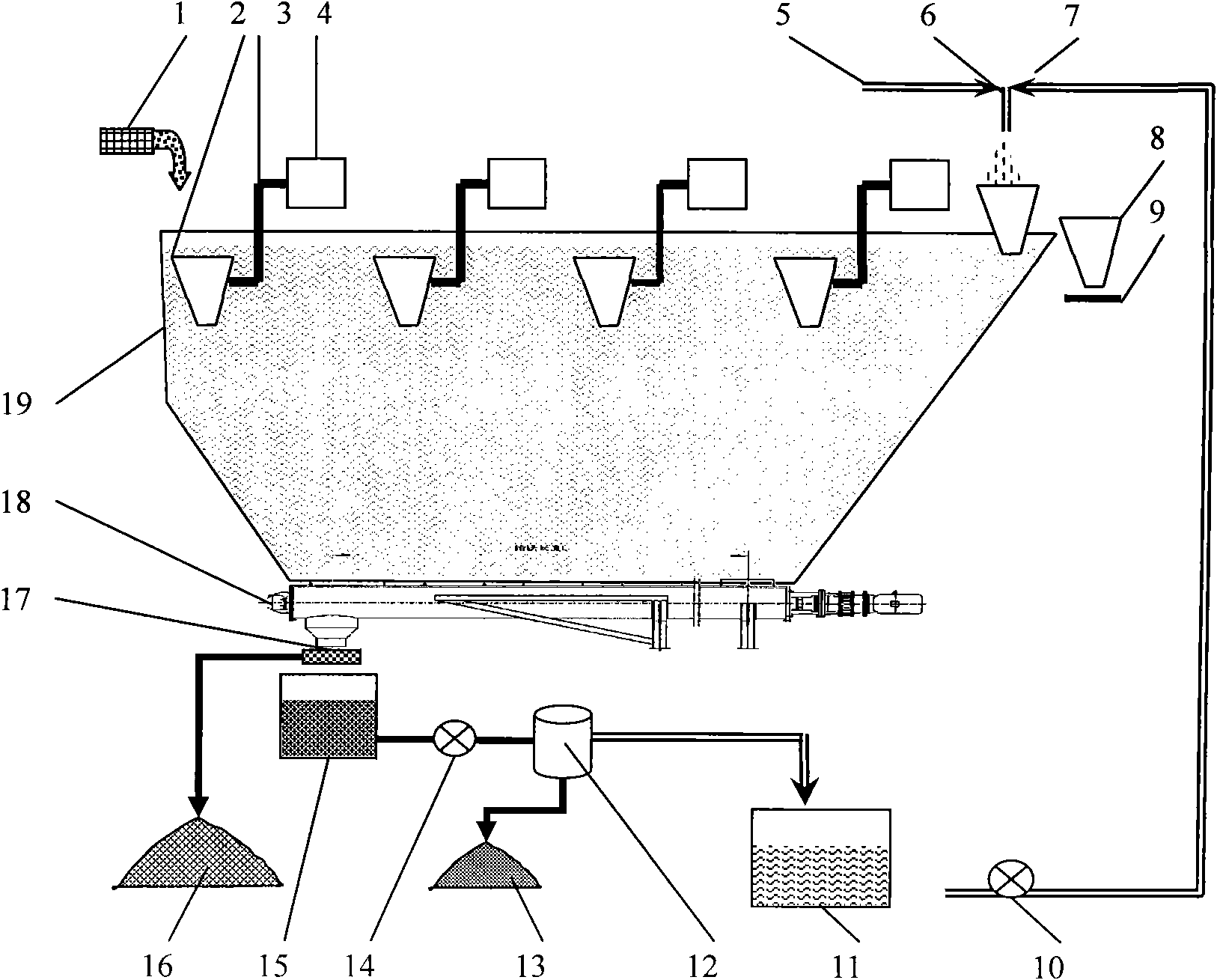

[0036] Depend on figure 1 It can be seen that the lump ore with a net powder content of 35% and a water content of 6.5% is soaked in the elutriation blue (2) under the water surface of the water tank (19) by the vibrating feeder (1); then the rotating device (4) is connected to the The rod (3) drives the elutriation basket (2) to rotate, first rotates to the left 10 times, then turns to the right 10 times, then stops the rotation, then the rotating device lifts the elutriation basket out of the water surface through the connecting rod, and then removes the powder contained in the elutriation basket The lump ore is introduced into the elutriation basket of the next elutriation device, and this is repeated to realize elutriation. After several times of elutriation for powder-containing lump ore, the elutriation basket (2) is lifted out of the water surface by the rotating device (4) through the connecting rod (3), and then transferred to the finished ore conveyor belt (9) by th...

Embodiment 2

[0039] Depend on figure 1 It can be seen that the lump ore with a net powder content of 25% and a water content of 5.5% is introduced into the elutriation blue (2) under the water surface of the water tank (19) from the vibrating feeder (1) for immersion; then the rotating device (4) is connected by connecting The rod (3) drives the elutriation blue (2) to rotate, first rotate 10 times to the left, then 10 times to the right, and then stop the rotation, then the rotating device lifts the elutriation blue out of the water surface through the connecting rod, and then the elutriation blue contains powder. The lump ore is introduced into the elutriation blue of the next elutriation device, and so on, to achieve elutriation. In order to improve the separation effect, after the powder-containing lump ore is washed for many times, when the water surface is raised for the last time, the lump ore is washed with the supplementary new water (5) and circulating water (7) through the flus...

Embodiment 3

[0042] The other parts of the washing and separating device containing powder block materials are the same as in Example 1. In order to facilitate the treatment of the bottom flow of the water tank, a bottom flow conveying device is set at the bottom of the water tank, and a solid-liquid separation device is connected after the bottom flow conveying device. The liquid separation device is composed of a high-frequency screen, a mud conditioning tank, a transfer pump, and a dehydrator in sequence. Depend on figure 1 It can be seen that the underflow material conveying device is a screw conveyor (18), and the underflow material in the water tank (19) is conveyed by the screw conveyor (18) to the high-frequency screen (17), and the material on the screen enters the coarse powder yard (16), and the underflow material is sieved. The material flows into the slurry conditioning tank (15) and stirs evenly, and is transported to the dehydrator (12) by the slurry pump (14) for processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com