Method for recovering organic nutrients and water in waste of organic synthesis industry

A technology for industrial waste and organic synthesis, which is used in chemical instruments and methods, solid waste removal, neutralization water/sewage treatment, etc. Effects of processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

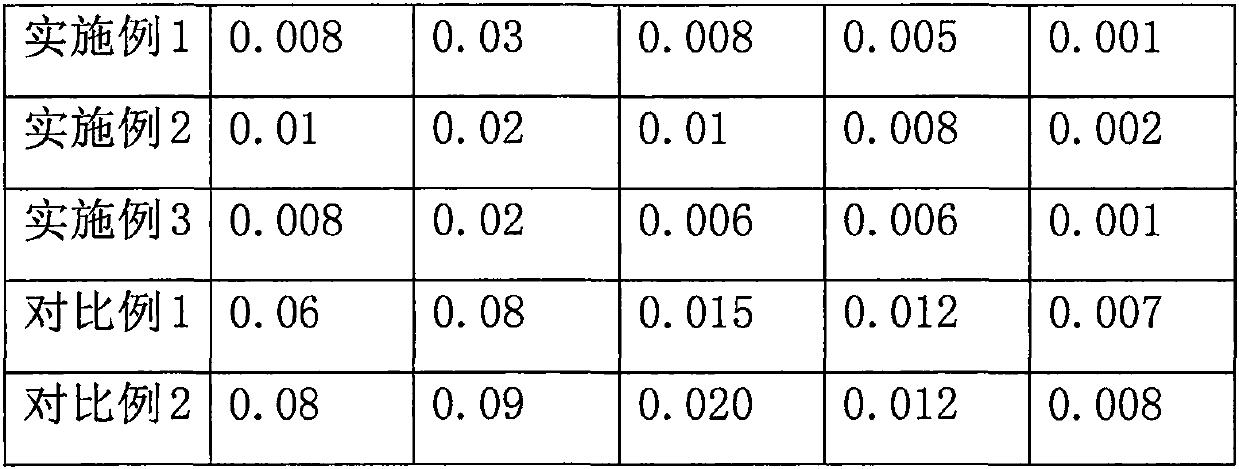

Embodiment 1

[0030] A method for reclaiming organic nutrients and water in organic synthetic industrial waste, comprising the steps of:

[0031] (1) filtering organic synthesis industrial waste to obtain solid organic products and waste liquid;

[0032] (2) carrying out to the organic product of step (1) gained is that 52% dilute nitric acid is carried out acidification with volume concentration, and at the temperature of 120 ℃, adjust pH value to be 1, dilute nitric acid addition is 4% of organic product quality, adds volume concentration Redox reaction is carried out for 35% hydrogen peroxide, natural sedimentation for 48 hours, the amount of hydrogen peroxide added is 3% of the quality of organic products, sedimentation filtration, adding 5% of the quality of organic products, including photosynthetic bacteria, lactic acid bacteria, yeast, Gram The positive actinomycetes and the EM flora of the fermented filamentous flora were subjected to liquid natural fermentation for 20 days to obta...

Embodiment 2

[0035] A method for reclaiming organic nutrients and water in organic synthetic industrial waste, comprising the steps of:

[0036] (1) filtering organic synthesis industrial waste to obtain solid organic products and waste liquid;

[0037] (2) carrying out acidification to step (1) gained organic product with volume concentration is that 50% dilute nitric acid is acidified, and at a temperature of 110° C., the pH value is adjusted to 0.5, and the dilute nitric acid addition is 3% of the organic product quality, adding volume concentration Carry out redox reaction for 30% hydrogen peroxide, settle naturally for 24 hours, the amount of hydrogen peroxide added is 2.5% of the organic product quality, sedimentation filtration, add 5% of the organic product quality, including photosynthetic bacteria group, lactic acid bacteria group, yeast group, Gram The positive actinomycetes and the EM flora of the fermented filamentous flora were subjected to liquid natural fermentation for 17 ...

Embodiment 3

[0040] A method for reclaiming organic nutrients and water in organic synthetic industrial waste, comprising the steps of:

[0041] (1) filtering organic synthesis industrial waste to obtain solid organic products and waste liquid;

[0042] (2) carry out acidification to step (1) gained organic product with the volume concentration of 51% dilute nitric acid, adjust the pH value to be 0.5 at a temperature of 115° C., the addition of dilute nitric acid is 3% of the organic product quality, add the volume concentration Redox reaction is carried out for 33% hydrogen peroxide, natural sedimentation for 30 hours, the amount of hydrogen peroxide added is 2.5% of the quality of organic products, sedimentation filtration, adding 5% of the quality of organic products, including photosynthetic bacteria, lactic acid bacteria, yeast, Gram The positive actinomycetes and the EM flora of the fermented filamentous flora were subjected to liquid natural fermentation for 18 days to obtain active...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com