Municipal sewage treatment method with zero energy consumption low sludge yield

A technology for urban sewage and treatment methods, which is applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, sustainable biological treatment, etc. problem, to achieve the effect of low sludge yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

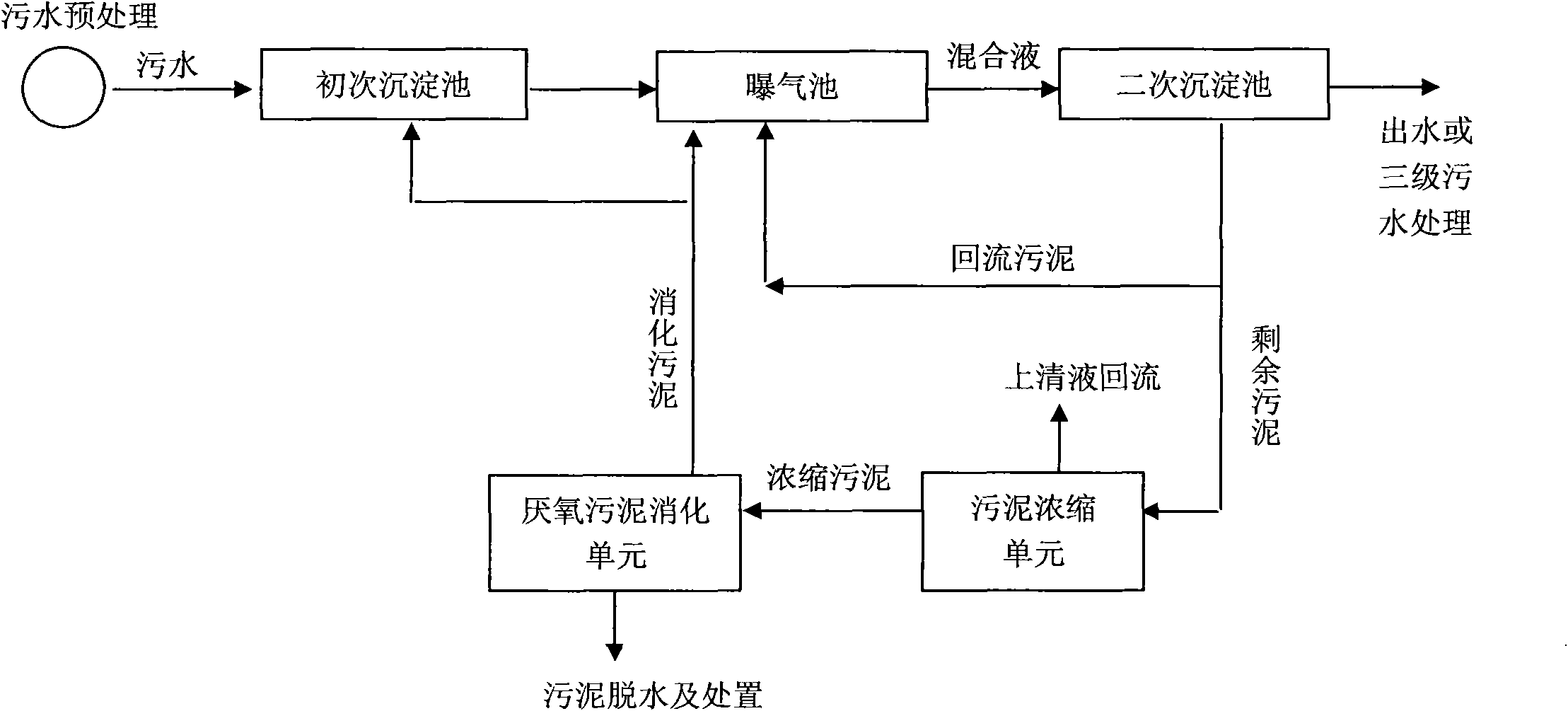

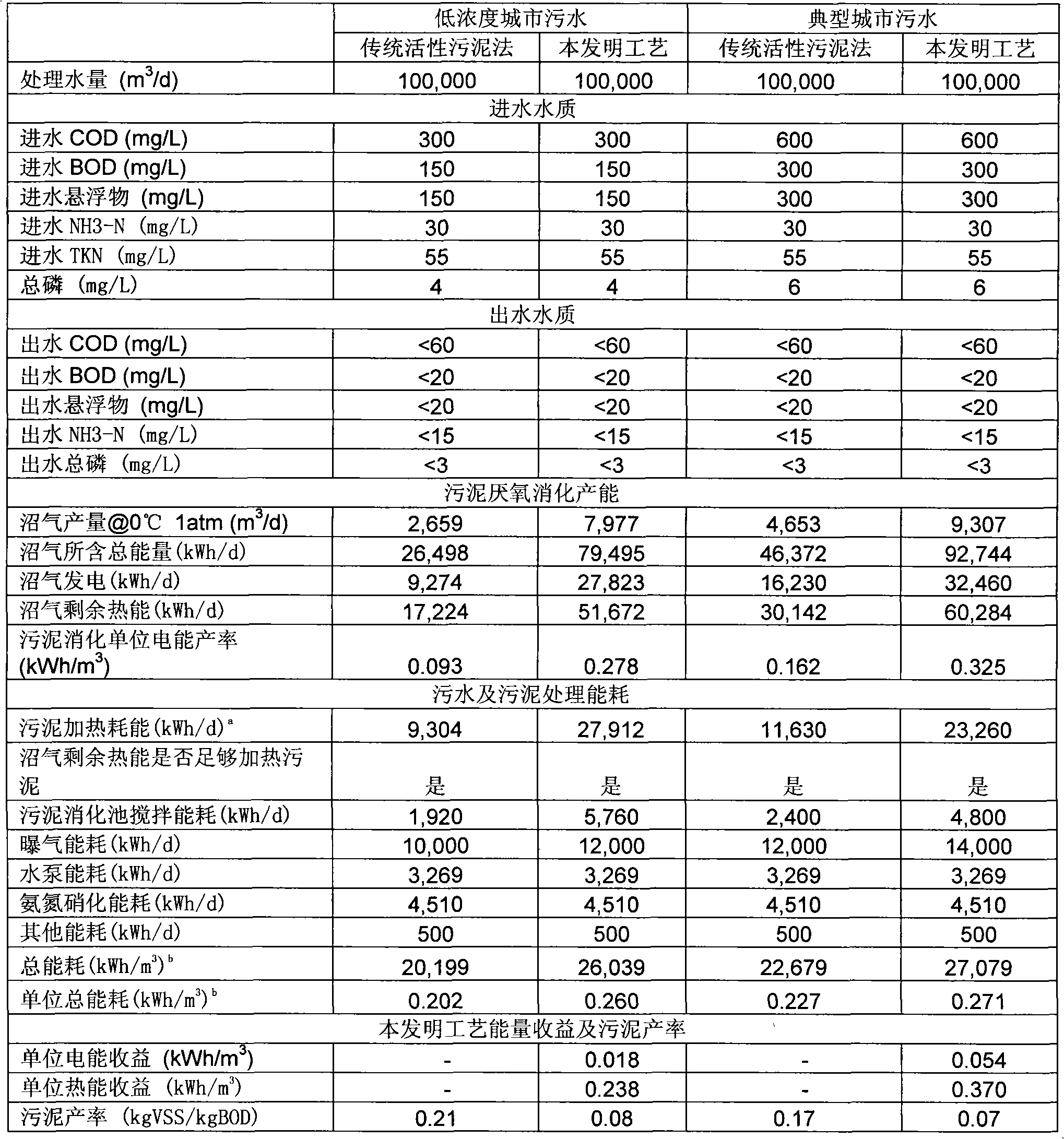

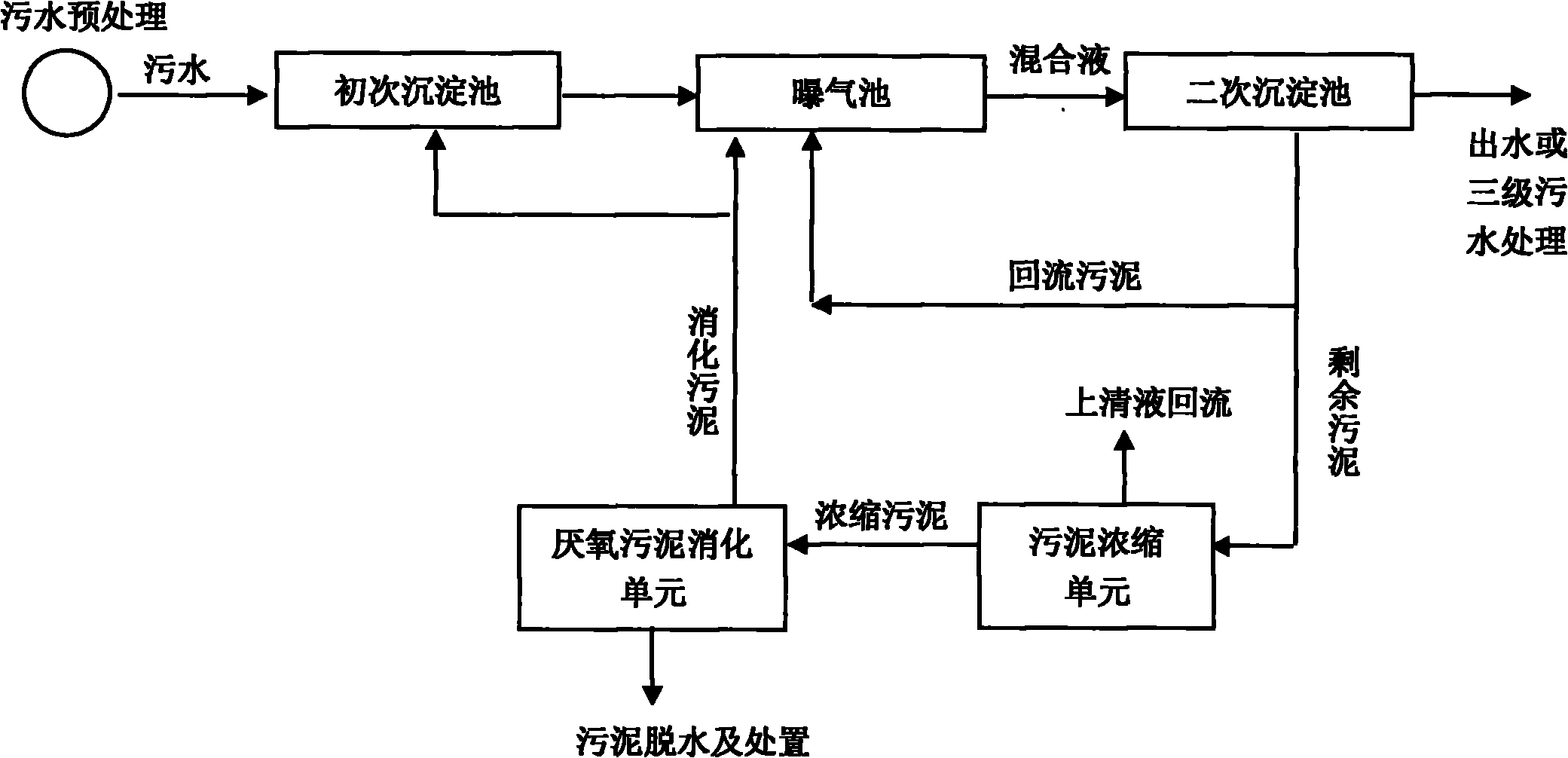

[0020] The invention provides a sewage treatment method with zero energy consumption and low sludge yield. Below in conjunction with Fig. 1, an example is given to illustrate the present invention.

[0021] The amount of sewage influent is 100,000 tons / day. The urban sewage pretreated by coarse and fine screens first enters the primary sedimentation tank to remove suspended particles with a large specific gravity, and then the effluent of the primary sedimentation tank, the returned activated sludge and the digested sludge returned by the sludge digestion tank enter together. The aeration tank forms a mixed solution. The aeration tank adopts the method of blast aeration, so that the mixed liquid is in a state of vigorous stirring and is in a suspended state. By controlling the dissolved oxygen content in the aeration tank, the dissolved oxygen content in the front section of the aeration tank is about 0.2mg / L, forming an anoxic section to facilitate the denitrification react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com