Method and complete set of equipment for making high-quality pore-forming agent by using waste straws

A technology of waste straw and complete equipment, which is applied in the production of high-quality porous ceramsite and the utilization of solid waste as a resource. It can solve the problems of large gas generation, poor grinding performance, and uneven pore structure of porous materials. Achieve the effect of accelerating the construction process and solving the surplus labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The method and complete set of equipment for preparing a high-quality pore-forming agent from waste straw mainly include two processes, namely: a heat treatment process and a ball milling and screening process. The equipment used includes: shear pulverizer, indirect contact rotary heating furnace, planetary ball mill, reciprocating vibrating multi-stage sieve.

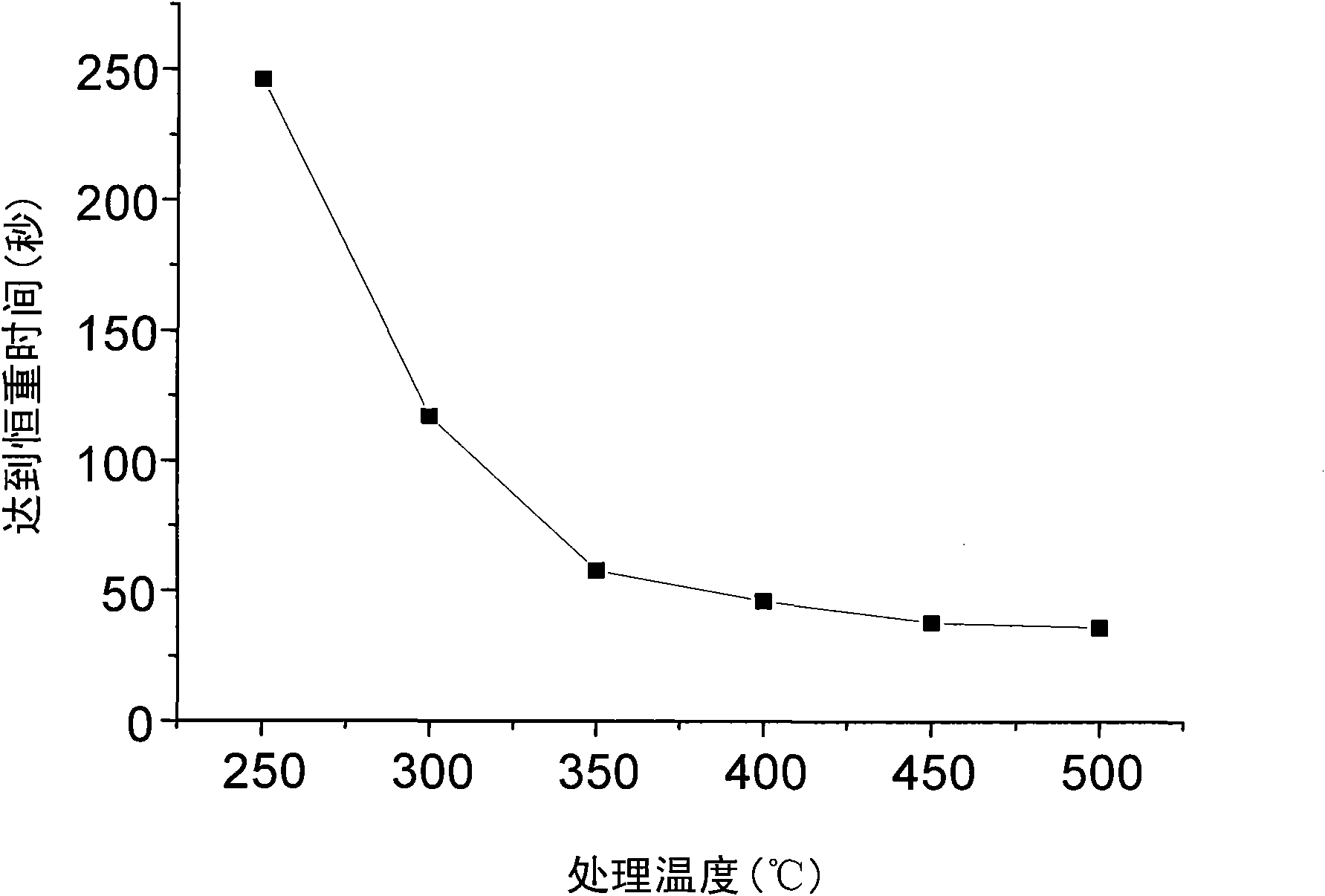

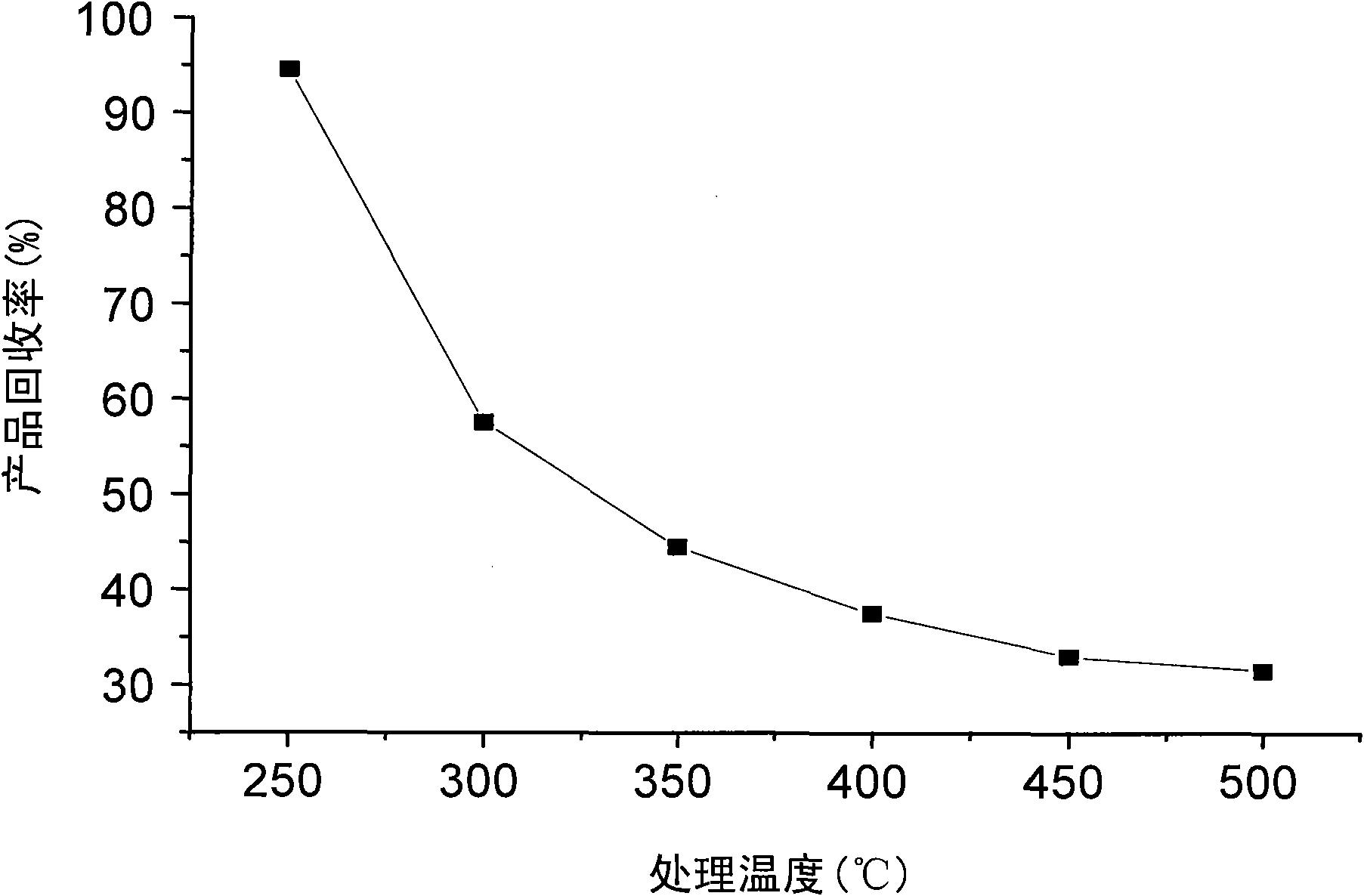

[0021] Heat treatment process: Take 100g of rice husk or rice straw, which needs to be crushed into pieces smaller than 2cm on a shearing mill, and then put into a quartz tube. The quartz tube is placed in an indirect contact electric tube furnace for heat treatment, the heating rate is controlled at 30°C / min, and the furnace temperature is kept at 300°C for 3 minutes. figure 1 It shows the relationship between different heating temperatures and the time required for the product to reach constant weight. Complete carbonization can be achieved at 300°C, and no open flame can be observed during the heat treatment ...

Embodiment 2

[0024] A method and a complete set of equipment for preparing a high-quality pore-forming agent from waste straw, including the following steps:

[0025] (a) Pretreatment: Utilize the shear pulverizer to cut the discarded straw into 1cm pieces;

[0026] (b) Heat treatment: loosely stack the sheared straw in an indirect contact rotary heating furnace, heat it to 300°C in an air atmosphere, control the heating rate at 35°C / min, stop heating after keeping it for 2 minutes, and let it cool naturally to room temperature;

[0027] (c) Grinding treatment: Grinding the carbonized stalk carbon in a planetary ball mill for 1 minute, the speed is controlled at 300 rpm;

[0028] (d) Classification treatment: use reciprocating vibration multi-stage sieve to classify the carbonized product after grinding, and the product can be divided into (1)>2mm pore-forming agent; (2)2mm-1mm pore-forming agent; (3) 1mm-0.5mm pore-forming agent; (4) 0.5mm-0.1mm pore-forming agent; (5) <0.1mm pore-formi...

Embodiment 3

[0030] A method and a complete set of equipment for preparing a high-quality pore-forming agent from waste straw, including the following steps:

[0031] (a) Pretreatment: Utilize the shear pulverizer to cut the discarded straw into 5cm pieces;

[0032] (b) Heat treatment: loosely stack the sheared straw in an indirect contact rotary heating furnace, heat to 400°C in an air atmosphere, control the heating rate at 25°C / min, stop heating after keeping for 5 minutes, and cool naturally to room temperature;

[0033] (c) Grinding treatment: Grinding the carbonized stalk carbon in a planetary ball mill for 5 minutes, the rotating speed is controlled at 100 rpm;

[0034] (d) Classification treatment: use reciprocating vibration multi-stage sieve to classify the carbonized product after grinding, and the product can be divided into (1)>2mm pore-forming agent; (2)2mm-1mm pore-forming agent; (3) 1mm-0.5mm pore-forming agent; (4) 0.5mm-0.1mm pore-forming agent; (5) <0.1mm pore-forming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com