Complex calcium lubricating grease and production technology thereof

A composite calcium-based grease and composite calcium-based technology are applied in lubricating compositions, petroleum industry, thickeners, etc., which can solve the problems of complex production raw materials and processes, limited hardening improvement, inconvenient use and storage, etc., and achieve Improvement of hardening phenomenon, improvement of hardening phenomenon, and effect of reducing the content of soap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

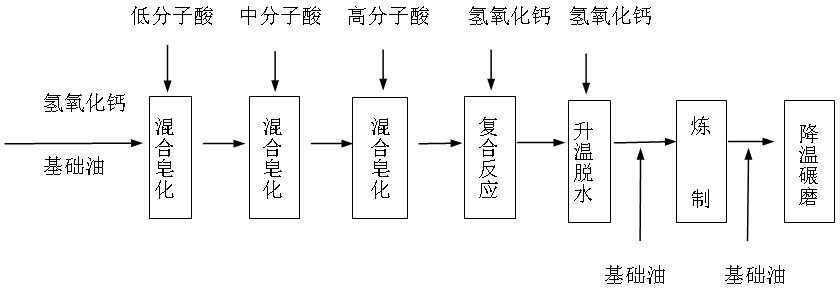

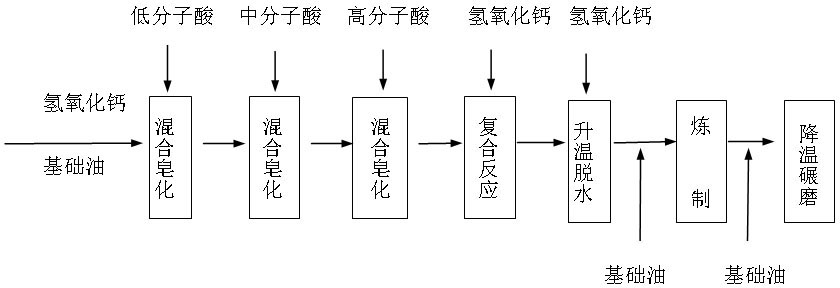

Method used

Image

Examples

Embodiment 1

[0016] Take the mixed oil of mineral oil and poly-α-olefin oil with a viscosity of 46sCt at 40°C: 539g is added to the fat-making kettle, and 73.20g of calcium hydroxide is added at the same time, and stirred evenly. Below 60°C, add 118.80g of glacial acetic acid, and stir for 40 minutes; then add 24g of adipic acid and 33.20g of sebacic acid, and stir for another 20 minutes; when the temperature rises to 90°C, add 49.50g of dodecyl hydroxystearic acid , stirred for 10 min and then heated to raise the temperature. Composite reaction at 90-150°C for 120 minutes. After 60 minutes of compounding, add 20.90 g of calcium hydroxide, and continue to heat up after compounding. When the temperature reaches 160-180°C, add 10.40 g of calcium hydroxide and 77 g of thickened oil. When the temperature continues to rise to 220-240°C, after heat preservation and refining for 5-15 minutes, add 154g of cooling oil, wait until the temperature is lowered to below 80°C, and grind twice with a thr...

Embodiment 2

[0018] Take the mixed oil of mineral oil and polyalphaolefin oil with a viscosity of 1000sCt at 40°C: 539g is put into the fat-making kettle, and 73.20g of calcium hydroxide is added at the same time, and stirred evenly. Below 60°C, add 118.80g of glacial acetic acid, and stir for 40 minutes; then add 24g of adipic acid and 33.20g of sebacic acid, and stir for another 20 minutes; when the temperature rises to 90°C, add 49.50g of dodecyl hydroxystearic acid , stirred for 10 min and then heated to raise the temperature. Composite reaction at 90-150°C for 120 minutes. After 60 minutes of compounding, add 20.90 g of calcium hydroxide, and continue to heat up after compounding. When the temperature reaches 160-180°C, add 10.40 g of calcium hydroxide and 77 g of thickened oil. When the temperature continues to rise to 220-240°C, after heat preservation and refining for 5-15 minutes, add 154g of cooling oil, wait until the temperature is lowered to below 80°C, and grind twice with a...

Embodiment 3

[0020] Take the mixed oil of mineral oil and polyalphaolefin oil with a viscosity of 40°C of 46sCt: 492.80g is added to the fat-making kettle, and 21.30g of calcium hydroxide is added at the same time, and stirred evenly. Below 60°C, add 34.40g of glacial acetic acid, and stir for 40 minutes; then add 7g of adipic acid and 9.80g of sebacic acid, and stir for another 20 minutes; when the temperature rises to 90°C, add 14.40g of dodecyl hydroxystearic acid , stirred for 10 min and then heated to raise the temperature. Composite reaction at 90-150°C for 120 minutes. After 60 minutes of compounding, add 6.10 g of calcium hydroxide, and continue to heat up after compounding. When the temperature reaches 160-180°C, add 3g of calcium hydroxide and 70.40g of thickened oil. When the temperature continues to rise to 220-240°C, after heat preservation and refining for 5-15 minutes, add 140.80g of cooling oil, wait until the temperature is lowered to below 80°C, and grind twice with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com