High-strength aluminum alloy material applicable to motorcycle rim

An aluminum alloy material, motorcycle technology, applied in rims, vehicle parts, transportation and packaging, etc., can solve the problems of not obtaining the quenching temperature, the material can not be fully quenched, reduce the temperature of the extruded bar, and achieve chemical polishing and bright performance. Good, low natural aging effect, good elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

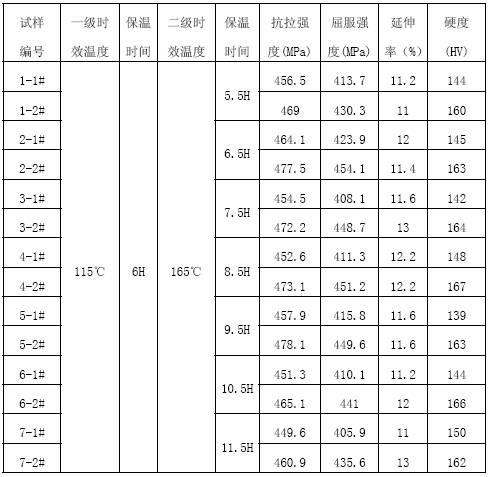

Image

Examples

Embodiment 1

[0021] Embodiment 1, the present invention provides a high-strength aluminum alloy material suitable for motorcycle rims, its components contain the following elements in mass percent: silicon 0.11; iron 0.15; copper 0.5; magnesium 1.35; manganese 0.13; zinc 5.9 ; titanium 0.06; chromium 0.13; zirconium 0.09; the rest is aluminum.

Embodiment 2

[0022] Embodiment 2, the present invention provides a high-strength aluminum alloy material suitable for motorcycle rims, its components contain the following elements in mass percent: silicon 0.13; iron 0.15; copper 1.3; magnesium 1.2; manganese 0.12; zinc 6.5 ; titanium 0.05; chromium 0.13; zirconium 0.10; the rest is aluminum.

[0023] The melting and casting process of the high-strength aluminum alloy material suitable for motorcycle rims comprises the following steps:

[0024] ⑴According to the above-mentioned component ratio, the ingredients except magnesium element are smelted in the furnace, and the temperature is 730-760 0 C, the time is 3h ~ 3.5h;

[0025] (2) According to the proportion of components, add magnesium element into the melting furnace, stir, and continue smelting for 0.5h, while removing slag;

[0026] ⑶ refining, the temperature is 720 ~ 750 0 C, the time is 15min, and the slag is removed at the same time;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com