Electro-hydraulic proportion control system of loader

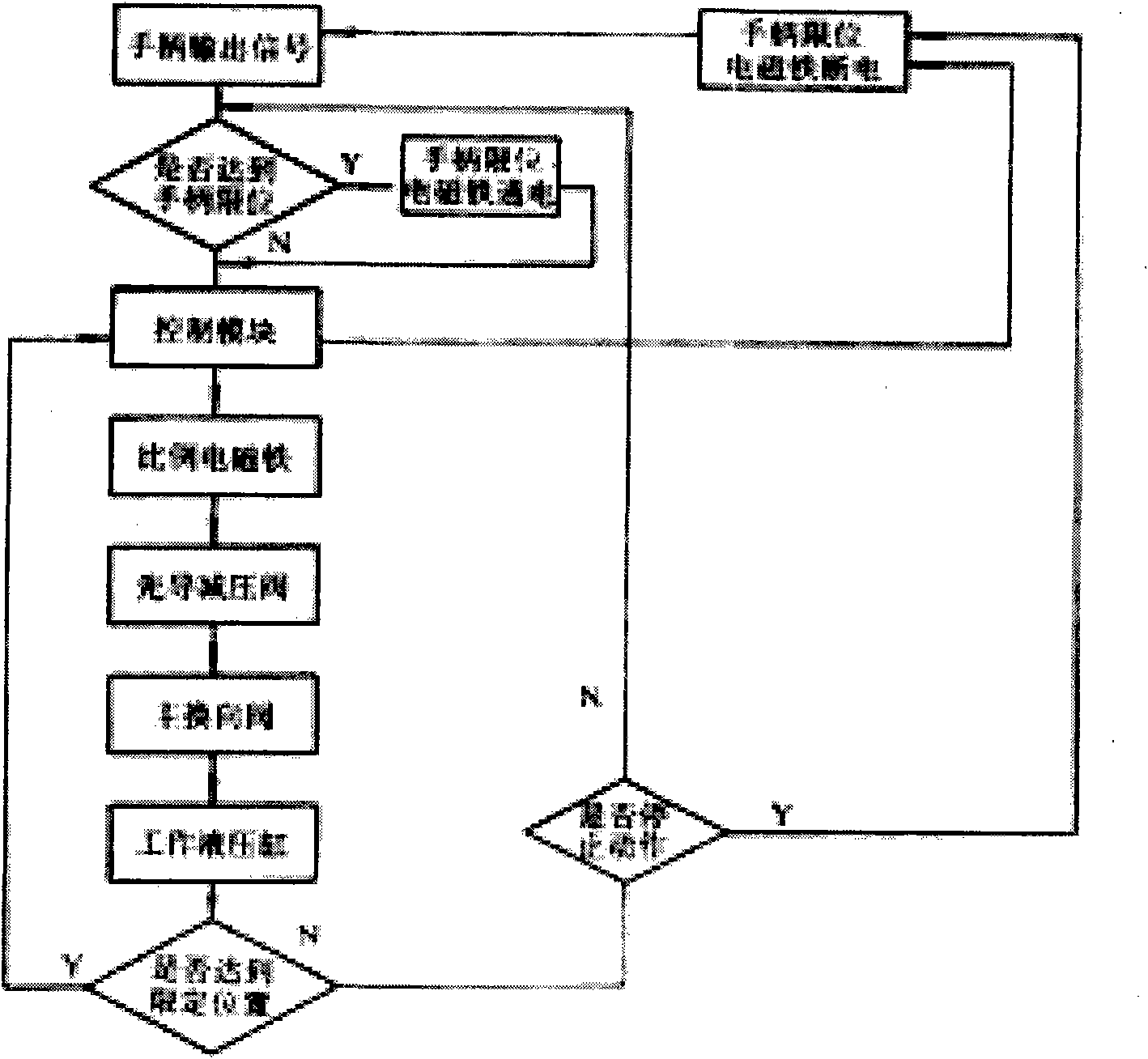

A proportional control, electromechanical hydraulic technology, applied in fluid pressure actuation system components, mechanical equipment, earth movers/shovels, etc., can solve the problems of uncontrollable reversing speed, single function, large operating force, etc., to achieve The effect of reducing labor intensity, reducing labor intensity, and reducing reversing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

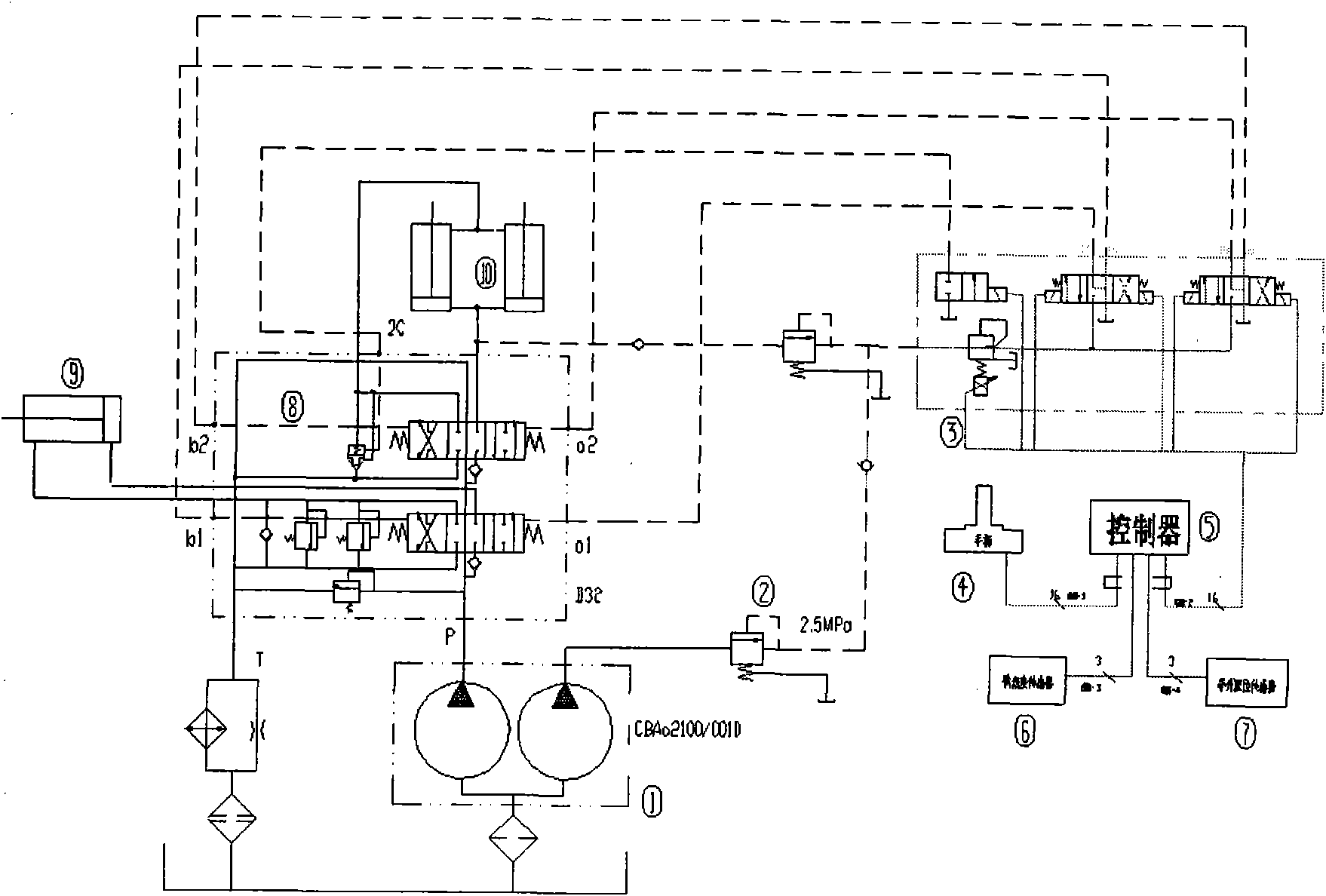

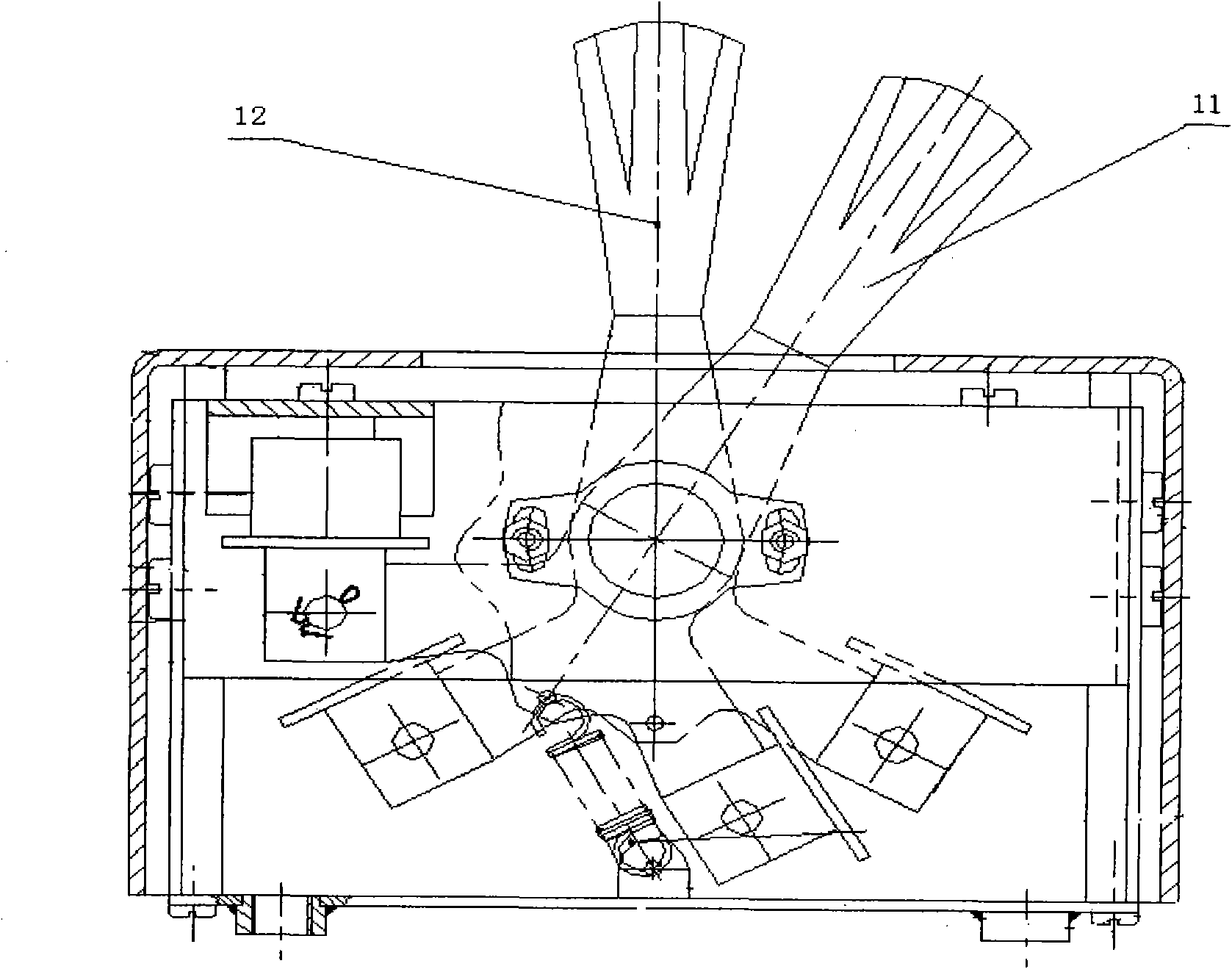

[0022] Embodiment 1: The control system includes: double oil pump 1, safety valve 2, pilot control valve group 3, operating handle 4, controller 5, boom positioning sensor 6, bucket level sensor 7, D32 multi-way valve 8, shovel Bucket oil cylinder 9, boom oil cylinder 10, bucket operating handle 11 and boom operating handle 12, the oil outlet of one oil pump of the double oil pump 1 is connected with the input port of the pilot control valve group 3 through the safety valve 2, and the operating handle 4, The boom positioning sensor 6 and bucket level sensor 7 are connected to the input end of the controller 5, and the output end of the controller 5 is connected to the control end of the pilot control valve group 3; the output end of the pilot control valve group 3 is connected to the D32 multi-way valve 8, the other oil pump of double oil pump 1 is connected to the input end of D32 multi-way valve 8, the output end of D32 multi-way valve 8 is connected to bucket cylinder 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com