Device for automatically testing performance of cable bunch

An automatic test device and cable harness technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as poor contact, low efficiency, and failure to detect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

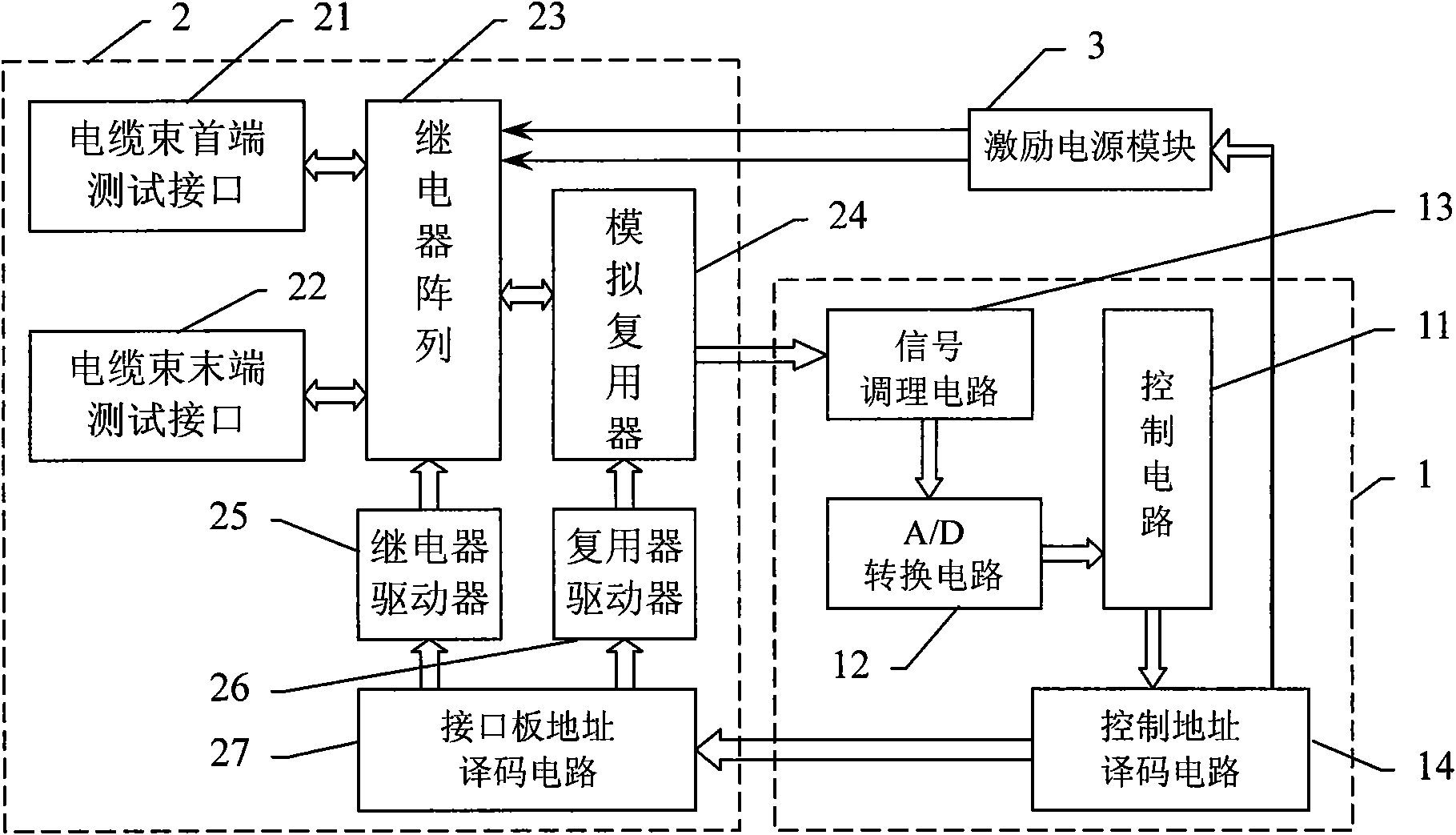

[0008] Specific implementation mode one: see figure 1 This embodiment will be described. The cable harness performance automatic test device described in this embodiment includes an excitation power supply module 3, a control measurement board 1 and a measurement interface board 2,

[0009] The control interface board includes a control circuit 11, a signal conditioning circuit 13, an A / D conversion circuit 12 and a control address decoding circuit 14, and the measurement address selection signal output terminal of the control circuit 11 is connected to the address selection signal input terminal of the control address decoding circuit 14 , the power control signal output end of the control circuit 11 is connected to the control signal input end of the excitation power module 3, and the two excitation power signal output ends of the excitation power module 3 are connected to the two excitation power signal input ends of the test interface board, A / D conversion The analog sign...

specific Embodiment approach 2

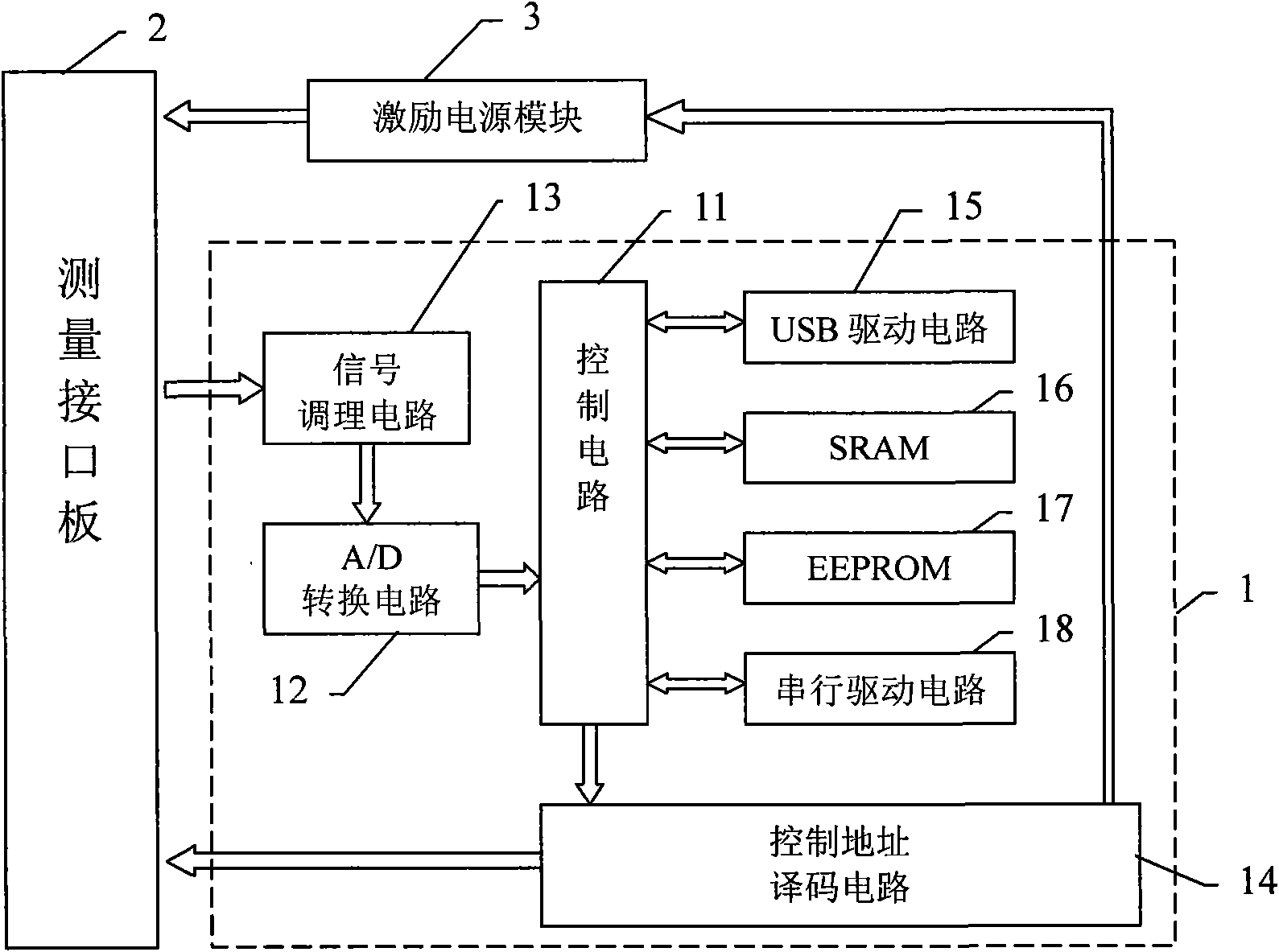

[0032] Specific embodiment two: The cable harness performance automatic testing device described in this embodiment is based on the technical solution described in specific embodiment one, and a serial drive circuit 18 is added, and the data of the serial drive circuit 18 The serial input / output terminal is connected to the serial data input / output terminal of the control circuit 11 .

[0033] The serial driving circuit 18 added in this embodiment can be realized by using an existing SPI communication driving circuit. After the serial driving circuit 18 is added, the cascade operation of multiple cable harness performance automatic testing devices can be realized.

[0034] In order to increase the communication speed and simplify the design, the synchronous serial peripheral interface SPI of the single-chip microcomputer C8051 is adopted in this embodiment, which provides a communication speed exceeding 2Mbps. The single-chip microcomputer SPI interface of the main test devic...

specific Embodiment approach 3

[0036] Specific embodiment three: The cable harness performance automatic test device described in this embodiment is based on the technical solution described in specific embodiment one or two, and a USB drive circuit 15 is added, and the serial number of the USB drive circuit 15 The row data input / output terminal is connected to the serial control data input / output terminal of the control circuit 11 .

[0037] The USB drive circuit 15 added in this embodiment can realize the communication function between the test device and the host computer. During the measurement process, the measured data obtained by the measurement is reported to the upper computer in real time through the USB drive circuit 15 . Described USB drive circuit 15 can adopt the device PDIUSBD12 type integrated circuit of PHILIPS company to be fully compatible with USB1. Just like a piece of RAM device externally expanded by the single-chip microcomputer, the main program is notified to handle the upper comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com