Device for removing sulfur dioxide in flue gas

A sulfur dioxide and desulfurization device technology, applied in the direction of inorganic chemistry, ammonia compounds, chemical instruments and methods, etc., can solve the problems of improving energy utilization rate, complex process, large equipment investment, etc., to improve service life, simplify process flow, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

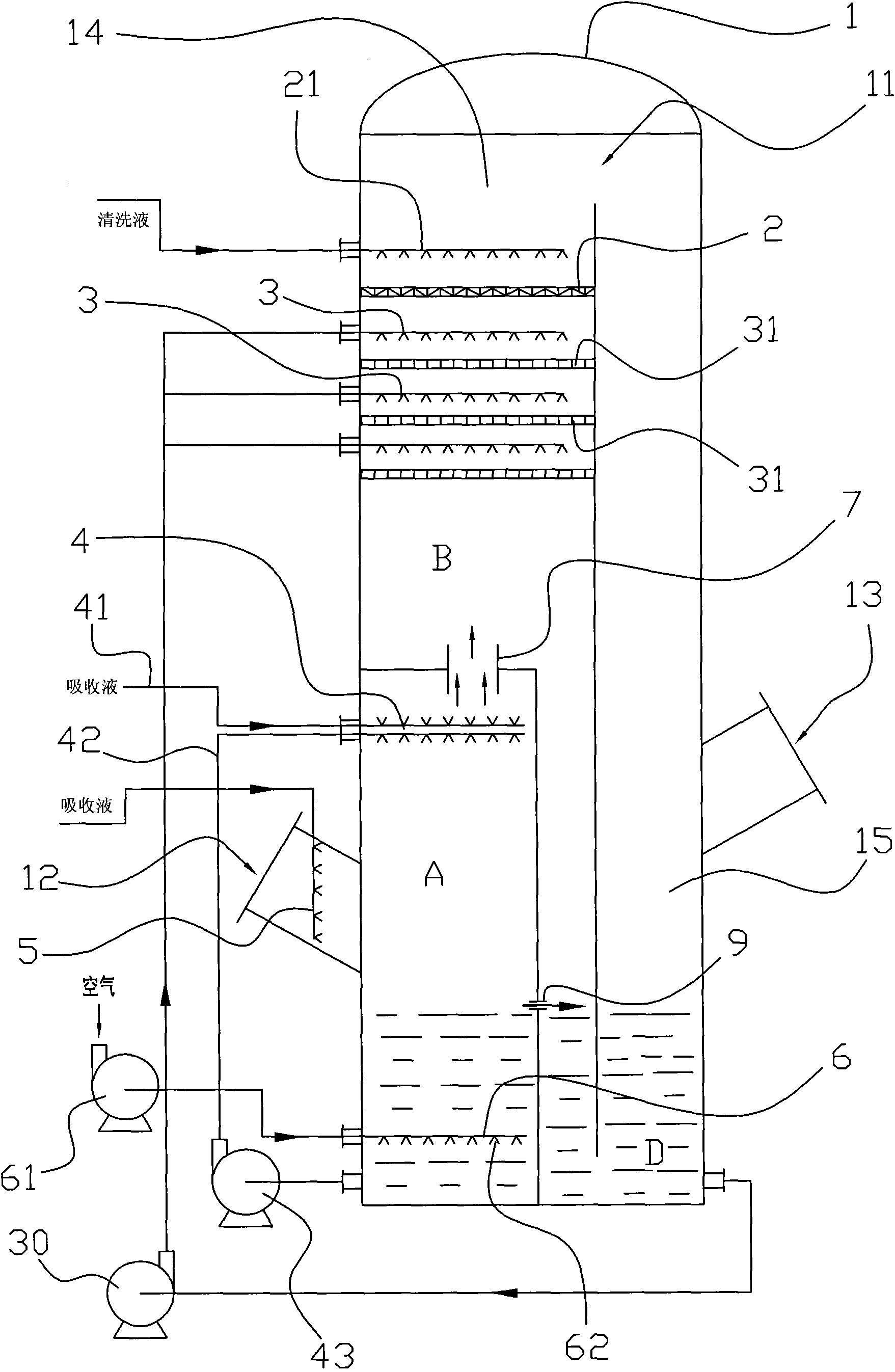

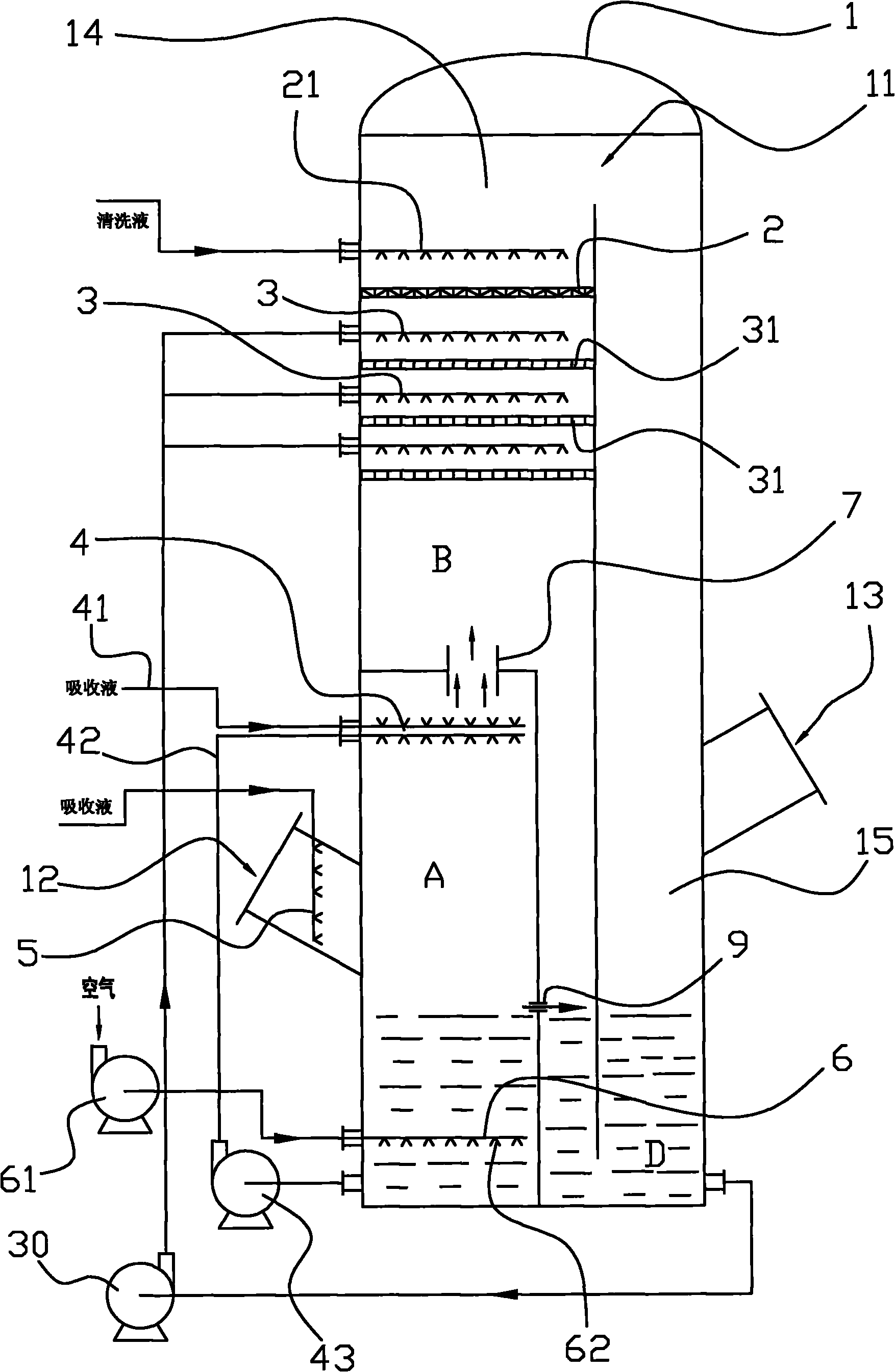

[0015] Such as figure 1 As shown, the device for removing sulfur dioxide in the flue gas in this embodiment includes a desulfurization tower 1, an oxidation device 6 for ammonium sulfite located at the lower part of the inner cavity of the desulfurization tower 1, and a demisting device 6 located at the upper part of the inner cavity of the desulfurization tower 1. Mechanism, outlet 13 for purifying gas to be emptied, and desulfurization device. The inner chamber of the desulfurization tower 1 is vertically divided into two parts, the front chamber 14 and the rear chamber 15, by a partition 8. The concentration area A and the desulfurization area B of the concentration device are arranged in the front chamber 14, and the flue gas inlet of the desulfurization tower 1 12 is provided with an absorption liquid atomizing device 5 . The flue gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com