Preparation method of Ba ion doped Na-beta'-Al2O3 solid electrolyte and solid electrolyte prepared by using same

A technology of solid electrolytes and ions, which is applied in the field of preparation of Na-β″-Al2O3 solid electrolytes, preparation methods and solid electrolytes prepared by this method, can solve problems limited to the theoretical calculation stage, and achieve a narrow range of particle size distribution , the composition is uniform, and the effect of improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

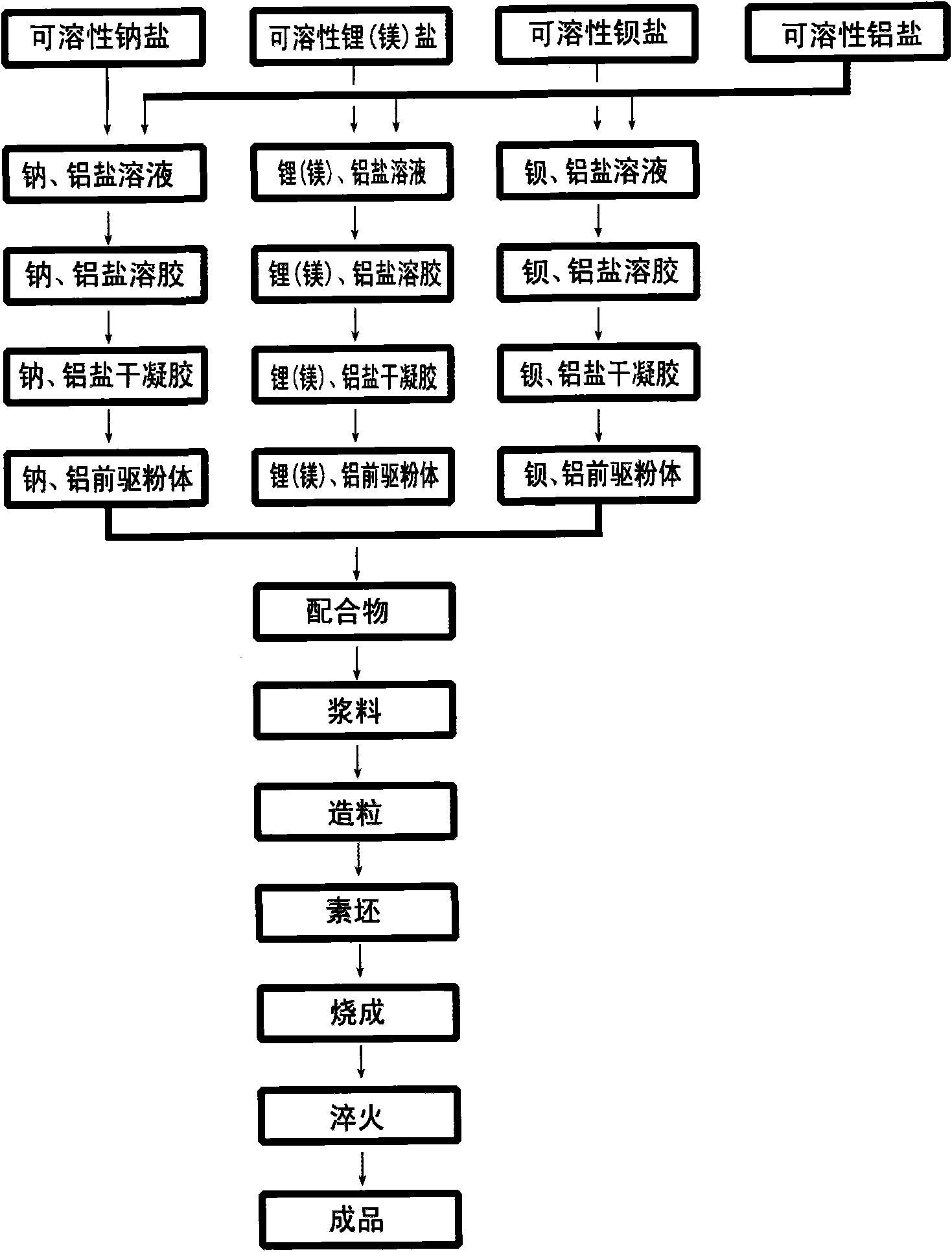

Method used

Image

Examples

Embodiment 1

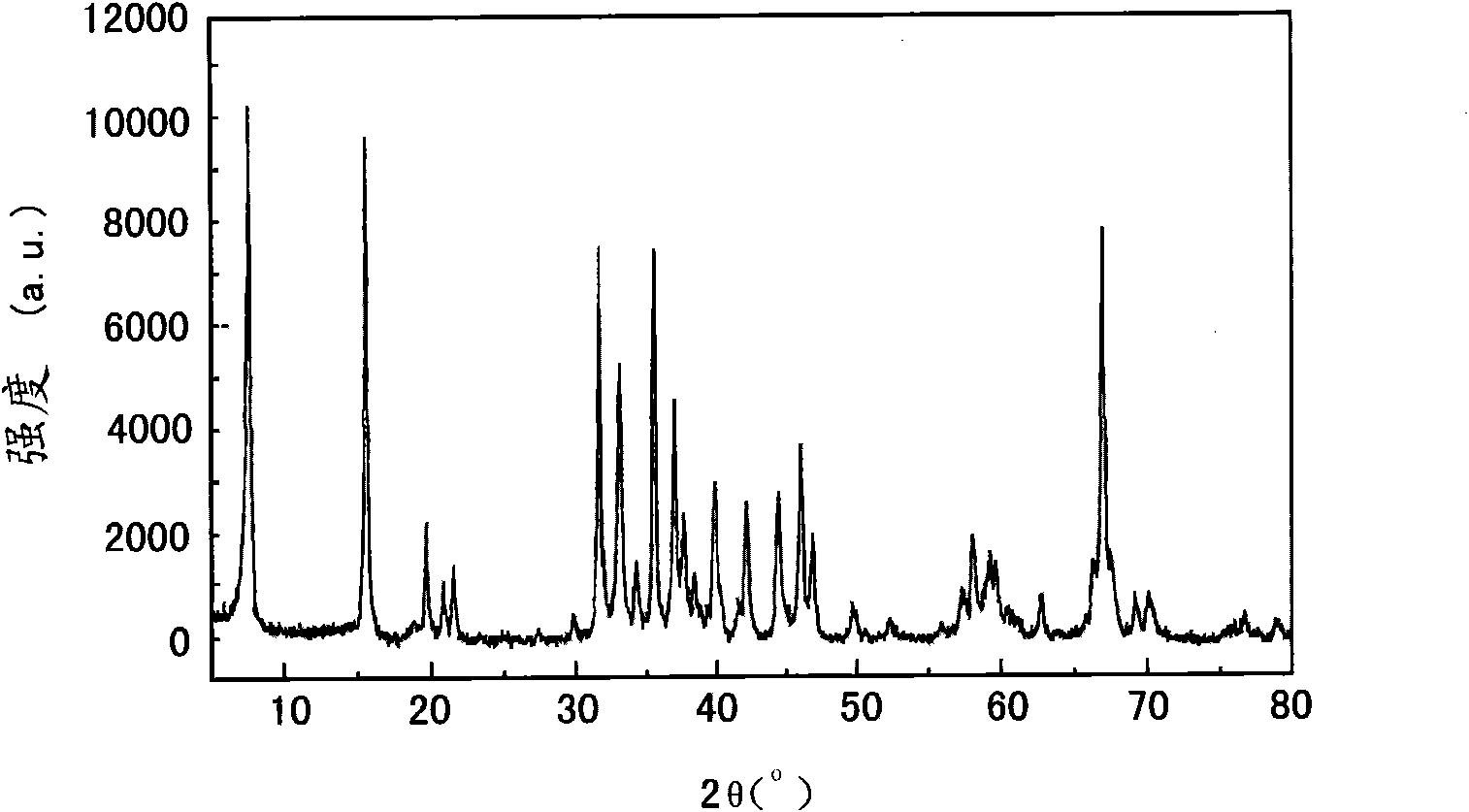

[0050] NaNO 3 , Al(NO 3 ) 3 9H 2 O as raw material, LiNO 3 As a stabilizer, Ba(NO 3 ) 2 As a regulator, according to the chemical formula of the intermediate target product is Na 2 O·5Al 2 o 3 , Li 2 O·5Al 2 o 3 and BaO·5Al 2 o 3 The stoichiometric ratio of metal elements, weighed 17.1601 grams of NaNO 3 and 378.6915 grams of Al(NO 3 ) 3 9H 2 O; Weigh 2.1574 g LiNO 3 and 58.6921 grams of Al(NO 3 ) 3 9H 2 O; Weigh 4.0887 grams of Ba (NO 3 ) 2 and 58.6911 grams of Al(NO 3 ) 3 9H 2 O, each group of salts was dissolved in deionized water as a solvent to prepare three solutions of 0.5 mol / L respectively. In the above three solutions, add C 6 h 8 o 7 ·H 2 O127.2801 grams, 19.7267 grams, 18.0825 grams, according to 1wt% of the sum of all metal salts in the dispersant and various solutions, add polyethylene oxide (PEO-600) 2.3218 grams, 0.3548 grams, 0.3741 grams respectively, respectively Adjust the pH=3 with diamine, and carry out stirring and mixing. T...

Embodiment 2

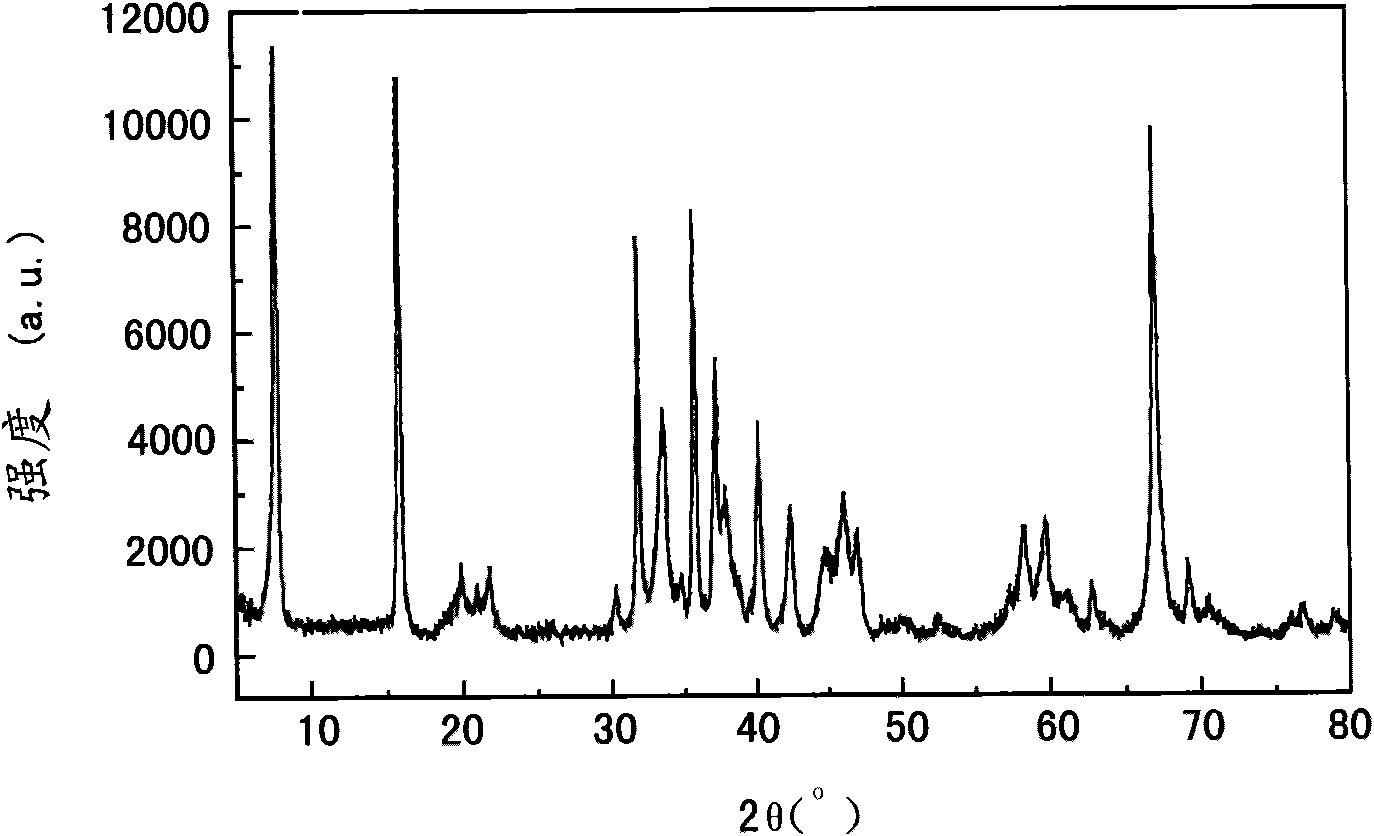

[0053] NaNO 3 , Al(NO 3 ) 3 9H 2 O as raw material, LiNO 3 As a stabilizer, Ba(NO 3 )2 As a regulator, according to the chemical formula of the intermediate target product is Na 2 O·5Al 2 o 3 , Li 2 O·5Al 2 o 3 and BaO·5Al 2 o 3 The stoichiometric ratio of metal elements, weighed 17.1601 grams of NaNO 3 and 378.6915 grams of Al(NO 3 ) 3 9H 2 O; Weigh 2.1574 g LiNO 3 and 58.6921 grams of Al(NO 3 ) 3 9H 2 O, weighed 4.0887 grams of Ba (NO 3 ) 2 and 58.6911 grams of Al(NO 3 ) 3 9H 2 O, each group of salts was dissolved in deionized water as a solvent to prepare three solutions of 0.5 mol / L respectively. In the above three solutions, add C 6 h 8 o 7 ·H 2 O84.8534 gram, 13.1511 gram, 12.0550 gram; Press the 0.2wt% of the sum of all metal salts in the dispersant and various solutions, add polyethylene oxide (PEO-600) 0.4644 gram, 0.0710 gram, 0.0748 gram respectively, use respectively Ethylenediamine was used to adjust the pH to 7, and stirred and mixed ...

Embodiment 3

[0056] NaNO 3 , Al(NO 3 ) 3 9H 2 O as raw material, LiNO 3 As a stabilizer, Ba(NO 3 ) 2 As a regulator, according to the chemical formula of the intermediate target product is Na 2 O·5Al 2 o 3 , Li 2 O·5Al 2 o 3 and BaO·5Al 2 o 3 The stoichiometric ratio of metal elements, weighed 17.1601 grams of NaNO 3 and 378.6915 grams of Al(NO 3 ) 3 9H 2 O; Weigh 2.1574 g LiNO 3 and 58.6921 grams of Al(NO 3 ) 3 9H 2 O; Weigh 4.0887 grams of Ba (NO 3 ) 2 and 58.6911 grams of Al(NO 3 ) 3 9H 2 O. Dissolve each group of salts in deionized water as a solvent to prepare three solutions of 3 mol / L. In the above three solutions, add C 6 h 8 o 7 ·H 2 O254.5602 grams, 39.4534 grams, 36.1650 grams, according to the 3wt% of the sum of all metal salts in the dispersant and each solution, add polyethylene oxide (PEO-600) 6.9653 grams, 1.0644 grams, 1.1224 grams respectively, respectively Adjust the pH to 1 with the amine, and carry out stirring and mixing. The heating rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com