Heat-dissipation paint for light-emitting diode (LED) lamp

A heat-dissipating coating and LED lamp technology, applied in the field of coatings, can solve the problems of poor temperature resistance and aging resistance, low bonding force of substrates, inconvenient construction, etc., and achieve stable mechanical properties, high bonding force, and good heat dissipation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

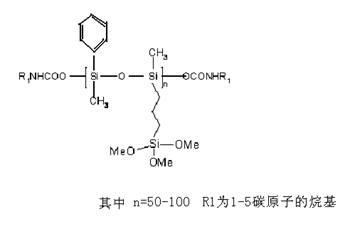

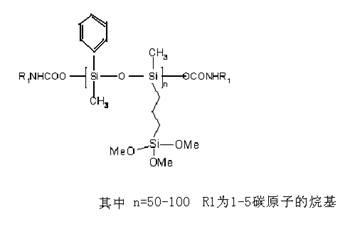

Method used

Image

Examples

Embodiment 1

[0012] 1. Proportion by mass percentage:

[0013] Silicone polyurethane prepolymer 30%,

[0014] Mixed solvent 20%,

[0015] Silane coupling agent KH560 5%,

[0017] Aluminum nitride, 29%,

[0018] Oleic Acid 1%.

[0019] 2. Preparation method:

[0020] Mix silicone-modified polyurethane prepolymer, mixed solvent, silane coupling agent KH%560, beryllium oxide, aluminum nitride and oleic acid and stir evenly in the reactor, grind to 5-10μm; stop grinding, pack .

[0021] During construction, spray heat-dissipating paint and dry at 200 degrees for 1 hour to form a film and make a 25-50 μm LE heat-dissipating coating.

[0022] Three, embodiment effect:

[0023] Artificial accelerated aging test under 80℃ and 300W ultraviolet irradiation conditions, the aging resistance time is 4800 hours, the temperature resistance is 250 degrees, the bonding shear force is 16MPa., and the thermal conductivity is 250W / (m·K).

Embodiment 2

[0025] 1. Proportion by mass percentage:

[0026] Silicone polyurethane prepolymer 50%,

[0027] Mixed solvent 10%,

[0028] Silane coupling agent KH560 1%,

[0030] Aluminum nitride, 24%,

[0031] Oleic Acid 5%.

[0032] 2. Preparation method:

[0033] The preparation method is the same as in Example 1.

[0034] Three, the effect of this embodiment:

[0035] Artificial accelerated aging test under 80°C and 300W ultraviolet irradiation conditions, the aging resistance time is 4800 hours, the high temperature resistance is 250 degrees, the bonding shear force is 19MPa., and the thermal conductivity is 268W / (m·K).

[0036]

Embodiment 3

[0038] 1. Proportion by mass percentage:

[0039] Silicone polyurethane prepolymer 40%,

[0040] Mixed solvent 10%,

[0041] Silane coupling agent KH560 2%,

[0043] Aluminum nitride, 38%,

[0044] Oleic Acid 1%.

[0045] 2. Preparation method:

[0046] The preparation method is the same as in Example 1.

[0047] Three, the effect of this embodiment:

[0048] Artificial accelerated aging test under 80°C and 300W ultraviolet irradiation conditions, the aging resistance time is 4850 hours, the high temperature resistance is 250 degrees, the bonding shear force is 20MPa., and the thermal conductivity is 290W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond shear | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Bond shear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com